As the HVAC industry transitions to low-GWP refrigerants, much attention has been placed on the new class of A2L refrigerants—mildly flammable alternatives to traditional high-GWP gases. While some technicians and homeowners have expressed hesitation over the term “flammable,” the reality is that A2L refrigerants like R-32 offer a safe and effective bridge to climate-friendly cooling when properly handled. In this article, we’ll explore the facts behind A2L refrigerant safety and explain why R-32 may be one of the most stable and manageable refrigerants in its class.

What Are A2L Refrigerants?

Under ASHRAE Standard 34, refrigerants are categorized by their toxicity (A or B) and flammability (1, 2L, 2, or 3). A2L refrigerants are:

-

Low toxicity (A)

-

Mildly flammable (2L)

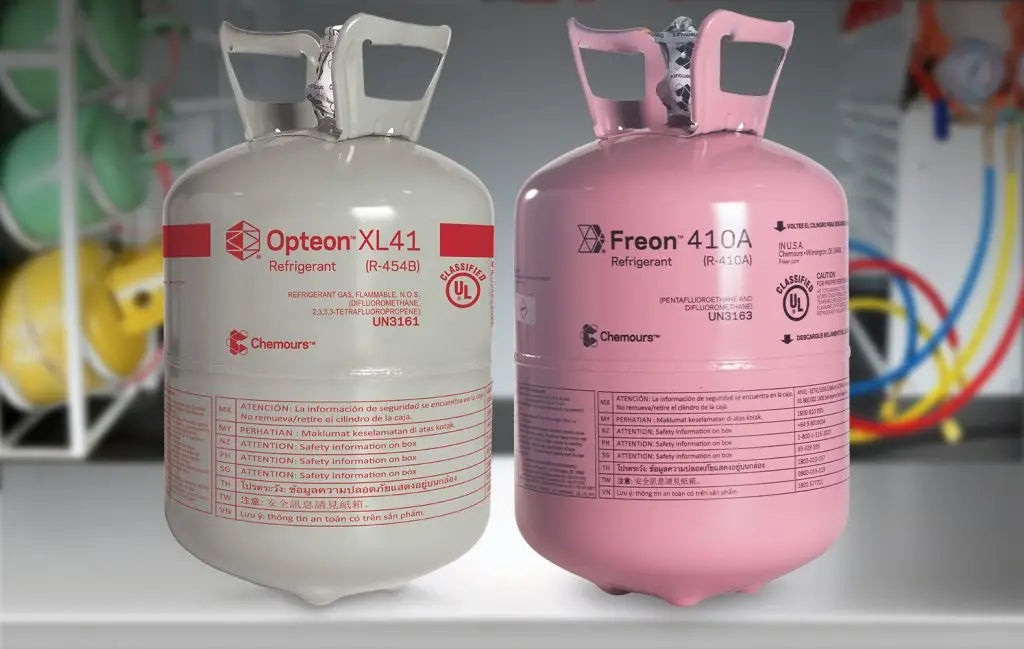

This classification includes refrigerants such as R-32 and R-454B, both of which are being adopted as eco-friendlier alternatives to R-410A. A2Ls are designed to have a lower Global Warming Potential (GWP) while maintaining acceptable performance.

For more details, see the ASHRAE safety classification guide.

R-32 Safety Profile: Separating Fact from Fiction

1. Lower Flammability Risk Than Common Fuels

R-32 is often labeled “flammable,” but the ignition characteristics of A2L refrigerants differ significantly from gases like propane or butane:

-

R-32 has a higher minimum ignition energy

-

It requires concentrations and conditions rarely found in residential HVAC applications

-

Flame propagation is limited and typically self-extinguishing in open environments

According to Honeywell’s technical comparison, R-32 is more stable and has lower combustion potential than many commonly used household gases.

2. Proven Safety Record in Global Markets

R-32 has been used in over 160 million residential AC units globally, especially in countries like Japan, Australia, and across the EU. Field data shows that incidents involving R-32 are extremely rare when standard safety protocols are followed.

Regulatory bodies, including the International Electrotechnical Commission (IEC), have reviewed and approved increased charge limits for R-32, signaling confidence in its safety.

3. Built-In Safety Mechanisms in HVAC Equipment

Modern R-32-compatible systems include:

-

Leak detection sensors

-

High-pressure cutouts

-

Flame-retardant construction materials

These design elements minimize risk even further and align with new UL and ISO standards for A2L installations.

Technician Training and Handling Protocols

Transitioning to R-32 does require proper technician training, including:

-

A2L-safe handling practices

-

Ventilation and leak mitigation

-

Equipment labeling and pressure-specific tools

Programs like the ESCO Institute’s R-32 training curriculum provide field technicians with the knowledge needed to handle R-32 safely and confidently.

Myths vs. Facts: A Quick Recap

| Myth | Reality |

|---|---|

| “R-32 is highly flammable.” | R-32 is classified as mildly flammable and requires strict conditions to ignite. |

| “A2Ls are dangerous in homes.” | Over 160 million R-32 units operate safely worldwide with minimal incidents. |

| “Technicians can’t work with R-32.” | Certified training programs are widely available and accessible. |

Why R-32 is the Practical A2L Choice

Between its strong safety record, efficiency advantages, and widespread availability, R-32 continues to be the A2L refrigerant of choice for leading HVAC manufacturers and contractors. It balances climate performance with safety, giving the industry a clear path forward.

For more on the technical and strategic case for R-32, see our full article on why standardizing on R-32 makes sense.

Final Thoughts

R-32 doesn’t just meet modern refrigerant safety standards—it exceeds them when paired with proper system design and technician training. As A2L refrigerants become the new norm, informed handling and industry-standard precautions make R-32 a safe, scalable solution for homes and businesses alike.