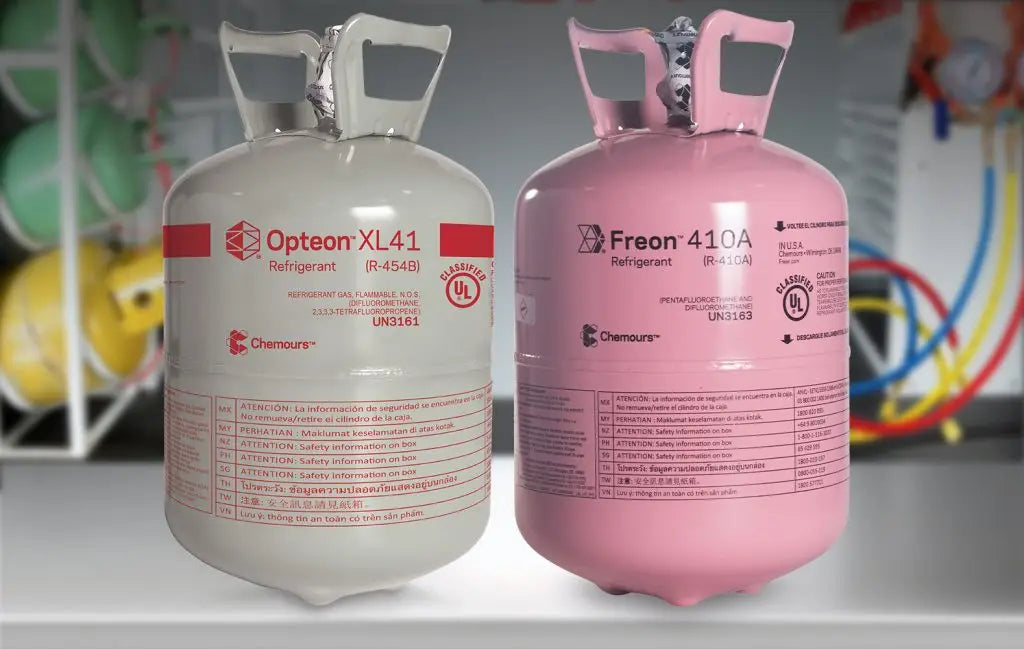

As HVAC professionals adapt to the new wave of A2L refrigerants, an often-overlooked but critical factor is serviceability. The choice between R-32 and R-454B extends beyond efficiency and environmental impact—how easy it is to service the system matters just as much for long-term ownership, technician workload, and warranty risk. In this article, we explain why R-32 systems offer superior serviceability over R-454B blends, making them the practical choice for contractors and manufacturers alike.

The Challenge with Blended Refrigerants Like R-454B

R-454B is a zeotropic refrigerant blend, composed of multiple components that boil at different temperatures. While this helps lower its Global Warming Potential (GWP), it introduces several maintenance issues:

-

Component separation: During a leak, lighter and heavier components escape at different rates, which can result in an off-ratio mixture.

-

Recharging difficulties: If the refrigerant charge is not recovered and replaced correctly, system performance may degrade.

-

Special handling requirements: R-454B must be charged in liquid phase, and improper recovery can lead to fractionation.

These factors mean that even minor service events require more careful handling, increasing the margin for error in everyday maintenance.

For more on blend behavior, see Honeywell’s guide on R-32 and R-454B.

Why R-32’s Simplicity Matters

Unlike R-454B, R-32 is a single-component refrigerant, meaning it doesn’t separate into different parts when leaked or recharged. This brings numerous advantages:

1. Straightforward Charging and Recovery

-

R-32 can be charged as a vapor or a liquid.

-

No risk of component imbalance from fractional loss.

-

Technicians can service systems faster and more accurately.

2. Reduced Risk of Performance Degradation

If an R-454B system is improperly recharged, performance can degrade due to chemical imbalance. With R-32, there's no such risk—what leaks out is exactly what gets replaced.

3. Fewer Technician Errors

Because R-32 has fewer variables, technicians don’t have to memorize complex blend ratios or follow specific charging angles. This reduces:

-

Callback rates

-

Equipment failure

-

Time spent troubleshooting refrigerant-related performance issues

Compatibility and Parts Management

Many HVAC manufacturers have streamlined their product lines to support R-32, meaning:

-

Fewer part SKUs across system types

-

Consistent training programs

-

Unified pressure charts and tools

Contractors benefit from faster repairs and reduced inventory management, which translates into lower operational costs.

Field-Tested Durability

In high-use, warm-climate installations, R-32 has shown strong stability and low service rates. A report from MAG HVAC found that R-32 units maintained higher output levels even after three seasons of use with minimal system drift.

Combined with its global adoption and technician familiarity, R-32’s track record continues to make it the most service-friendly low-GWP refrigerant on the market.

Final Word: Serviceability Should Drive Refrigerant Strategy

While environmental and regulatory factors rightfully shape refrigerant selection, HVAC professionals must also consider what happens after installation. R-32 offers the best combination of simplicity, reliability, and efficiency in service—qualities that reduce cost, downtime, and risk over the lifetime of the unit.

For a broader comparison, explore our pillar article on R-32 vs. R-454B.