When I installed my Goodman 3-Ton 15 SEER2 Heat Pump System, I quickly learned that no matter how efficient or well-built a system is, sooner or later you’ll face a day when it doesn’t heat or cool like it should.

The good news? Most of the time, it’s not a major failure. It’s usually something simple — a tripped breaker, a clogged filter, or even a thermostat glitch.

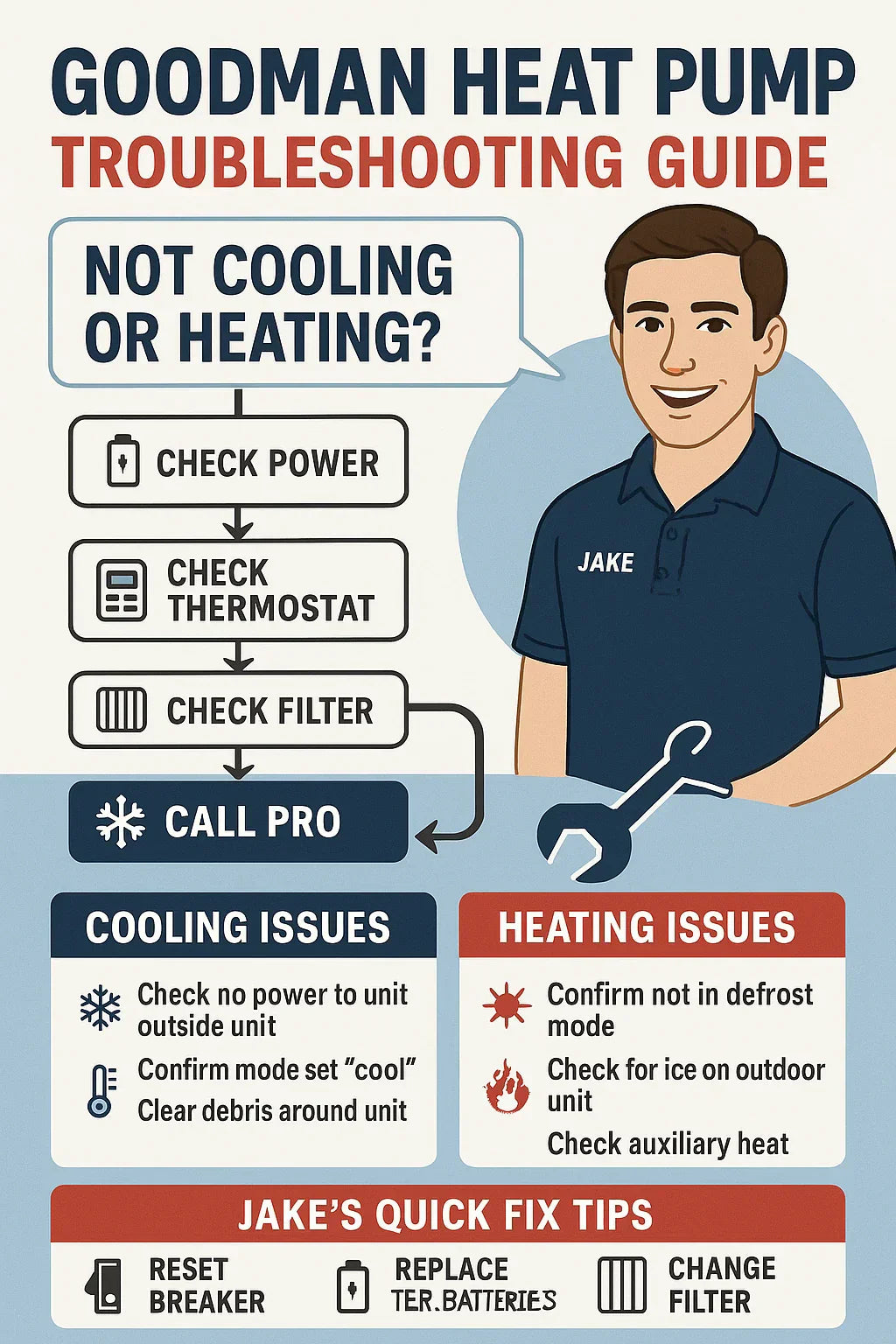

This step-by-step troubleshooting guide walks you through exactly what to check before calling a technician — based on my own hands-on experience maintaining a Goodman system in real-world conditions.

🏁 1. When Your Heat Pump Stops Doing Its Job

Imagine this: it’s the hottest afternoon of July, and your Goodman system is blowing warm air instead of cool. Or it’s a frosty January morning, and the heat pump just… won’t heat.

Your first instinct might be panic, but don’t worry — about 70% of these issues come down to simple fixes you can handle safely at home.

This guide covers:

-

✅ How to diagnose both no-cooling and no-heating problems.

-

✅ What’s safe for DIY troubleshooting.

-

✅ When to call in a certified HVAC technician.

Safety note:

Always turn off power at the breaker panel before removing any covers or working near electrical components.

⚙️ 2. How Your Goodman Heat Pump Works (In Plain English)

A heat pump isn’t magic — it’s a two-way air conditioner. In summer, it moves heat out of your home. In winter, it reverses the process and moves heat in.

Key Components

-

Compressor: circulates refrigerant through the system.

-

Reversing Valve: switches the refrigerant flow between heating and cooling modes.

-

Condenser Coil (Outdoor Unit): releases or absorbs heat.

-

Evaporator Coil (Indoor Unit): absorbs or releases heat depending on mode.

-

Air Handler: blows air through your ducts.

-

Thermostat: tells the system when to heat, cool, or rest.

If any of these components lose power, get blocked, or miscommunicate, your system won’t function correctly.

👉 For model diagrams and wiring layouts, check the Goodman Product Manual Library.

🧭 3. The Smart Way to Troubleshoot

Before you grab a wrench, remember Jake’s Three Rules of Heat Pump Troubleshooting:

-

Start with the basics. Check for power, thermostat settings, and airflow.

-

Observe behavior before acting. Note sounds, airflow, and lights.

-

Work from simple to complex. Fix small, obvious issues before assuming a major failure.

Here’s a quick cheat sheet to get oriented:

| Symptom | Likely Cause | Quick Fix |

|---|---|---|

| System won’t turn on | Breaker tripped or thermostat issue | Reset breakers; check thermostat |

| Blows warm air in cool mode | Wrong mode or reversing valve stuck | Verify thermostat mode |

| Coils frozen | Low airflow or refrigerant | Replace filter; thaw coils |

| Runs nonstop | Dirty coil, undersized unit, or thermostat error | Clean coils; recalibrate thermostat |

| No heat in winter | Defrost problem or low refrigerant | Check outdoor coil; call pro |

🔋 4. Step 1: Check Power and Breakers

You’d be amazed how often this is the culprit.

🧾 Checklist

-

Confirm your thermostat display is lit — if not, replace batteries or check the air handler fuse.

-

Check both indoor (air handler) and outdoor (condenser) breakers in your main electrical panel.

-

If tripped, reset them fully OFF → ON.

-

-

Verify the disconnect switch near the outdoor unit is seated properly.

-

Inspect nearby GFCI outlets — if tripped, press “Reset.”

After restoring power, wait at least 5 minutes before restarting the thermostat. Heat pumps have built-in delay protection for compressors.

🌡️ 5. Step 2: Confirm Thermostat Settings

Your thermostat is the brain of your system — but even smart brains need reminders.

🧭 Steps to Check

-

Set the thermostat to HEAT (winter) or COOL (summer).

-

Set the fan mode to “AUTO.” (“ON” will just circulate air, not condition it.)

-

Lower or raise the setpoint by at least 3°F to trigger the system.

-

Ensure no “HOLD” program is locking in an old schedule.

-

For Wi-Fi thermostats, check app connectivity and power module.

Jake’s pro tip:

“A dead thermostat battery can mimic a total system failure. Replace those first — it’s a $5 fix.”

If the thermostat clicks but the unit doesn’t start, proceed to airflow checks next.

💨 6. Step 3: Inspect Airflow and Filters

Clogged filters and blocked vents are the number one reason for poor performance.

🧰 Steps:

-

Turn off the system.

-

Pull out the return filter and inspect it. If you can’t see light through it — it’s dirty.

-

Replace with a new MERV 8–10 pleated filter.

-

Check that all supply and return registers are open and unobstructed.

-

Inspect ducts for loose or disconnected joints.

If you hear the indoor blower but still feel weak airflow, remove the blower door and inspect the evaporator coil — if covered in dust or ice, clean it gently with coil cleaner or let it thaw.

Resource: EnergyStar Duct & Filter Maintenance Guide.

🧊 7. Step 4: Check the Outdoor Condenser (Cooling Issues)

If your Goodman unit runs but isn’t cooling, focus outside.

🧾 Checklist

-

Listen for the compressor hum and fan movement.

-

No fan sound? Check for debris, sticks, or leaves lodged under the grille.

-

If the fan motor doesn’t spin freely, shut off power and try turning the blade by hand — stiffness indicates a bad bearing or capacitor.

-

-

Clean the condenser coil fins using a gentle garden hose spray (no high pressure).

-

Inspect refrigerant lines for frost buildup or oily residue (sign of a leak).

If the fan runs but the air from vents is warm, the issue may involve refrigerant or a faulty reversing valve — both require professional service.

🔁 8. Step 5: If the System Won’t Heat

During winter, your heat pump reverses operation. When it fails, follow this flow:

🧰 Quick Checks

-

Make sure it’s not in defrost cycle. During defrost, the unit temporarily blows cool air indoors while melting ice from the outdoor coil — this is normal and lasts 2–5 minutes.

-

Check thermostat mode: should read HEAT, not EMERGENCY HEAT.

-

Inspect outdoor coil for frost or ice accumulation.

-

If frozen, shut off system and allow ice to melt naturally.

-

Once clear, restart system and listen for compressor engagement.

If heat still won’t come on, possible causes include:

-

Defrost sensor malfunction.

-

Faulty reversing valve.

-

Low refrigerant charge.

👉 Refer to EnergyStar’s Cold Climate Heat Pump Guide for details on winter operation.

⚠️ 9. Step 6: Decode Goodman’s Error Lights or Codes

Most Goodman air handlers have small diagnostic LEDs visible through the panel.

| Flash Pattern | Meaning | Fix |

|---|---|---|

| 1 Flash | System lockout due to restart limit | Turn off power for 5 min; restart |

| 3 Flashes | Pressure switch open | Check filter, coil, and vents |

| 4 Flashes | High temp limit reached | Check airflow and clean coils |

| Continuous Flash | Thermostat call active | Normal operation |

If you see steady flashing + no response, it could be a low-voltage issue — check thermostat wiring and fuses.

Model-specific codes are in Goodman’s Product Technical Manuals.

🧠 10. Step 7: Test Auxiliary / Emergency Heat

When temps dip below 25°F, the auxiliary heat strips inside the air handler automatically help your system maintain comfort.

To test:

-

Set thermostat 3–4°F above current temp.

-

“AUX HEAT” or “EMERGENCY HEAT” should display.

-

If the blower runs but air remains cool:

-

Check the air handler breaker.

-

Ensure control board wiring (W2 or E terminals) is intact.

-

If heat still fails, the strip element or relay may need replacement.

-

Jake’s note:

“Aux heat is your backup quarterback. If it’s playing every down, something else is off — usually refrigerant or defrost control.”

🧊 11. Step 8: Dealing with a Frozen Outdoor Unit

Frozen coils are one of the most common cold-weather calls.

🧊 What to Do

-

Turn off your system immediately — running while iced can damage the compressor.

-

Allow the ice to thaw naturally (don’t use sharp tools or pour hot water).

-

Once thawed, clear debris around the base and ensure at least 24 inches of clearance for airflow.

-

Restart and observe operation — defrost should kick in as needed.

If icing repeats within 24 hours, call a pro. It could signal:

-

Defective defrost sensor.

-

Stuck reversing valve.

-

Low refrigerant pressure.

🔋 12. Step 9: System Running Constantly or Short Cycling

Constant Running

If your Goodman heat pump runs nonstop:

-

Check for dirty coils, clogged filters, or open windows.

-

Verify thermostat placement (not near lamps or vents).

-

Confirm refrigerant line insulation is intact.

Short Cycling

If your system turns on/off every few minutes:

-

Check for low refrigerant (pro job).

-

Ensure condensate drain isn’t backed up (float switch may cut power).

-

Replace thermostat batteries and recalibrate.

Frequent short cycling wears down compressors fast — if this persists, call a technician for diagnosis.

⚡ 13. Step 10: Know When to Call a Professional

Some problems are safe to diagnose; others require specialized tools and EPA certification.

Call a licensed HVAC technician if:

-

You see ice on refrigerant lines.

-

Breakers trip repeatedly.

-

You smell burning plastic or ozone.

-

The compressor hums but never starts.

-

The unit blows warm air in both modes.

To find certified help, visit EnergyStar’s HVAC Contractor Locator or contact a Goodman-authorized dealer.

🧾 14. Preventative Maintenance Checklist

Keeping your Goodman system running smoothly is 90% maintenance, 10% luck.

| Task | Frequency | Tools/Notes |

|---|---|---|

| Replace air filter | Every 3 months | MERV 8–10 |

| Clean outdoor coil | Spring/Fall | Gentle water rinse |

| Flush drain line | Annually | Mix vinegar & warm water |

| Check thermostat calibration | Annually | Compare with digital thermometer |

| Inspect refrigerant lines | Seasonally | Ensure insulation intact |

| Schedule pro inspection | Annually | Include refrigerant and pressure checks |

Jake’s mantra:

“Good maintenance costs a few minutes now — bad maintenance costs hundreds later.”

🧩 15. Quick-Reference Troubleshooting Chart

| Problem | Common Cause | Quick Fix | Pro Needed? |

|---|---|---|---|

| No power | Tripped breaker | Reset circuit breakers | ❌ |

| Fan runs, no cooling | Low refrigerant | Clean coils, call tech | ✅ |

| Warm air in cool mode | Wrong thermostat setting | Reset to “Cool” | ❌ |

| Frozen coils | Dirty filter | Replace filter | ❌ |

| Loud humming | Bad capacitor | Shut off system | ✅ |

| Weak heating | Defrost issue | Inspect outdoor coil | ⚠️ |

| Unit cycles rapidly | Low charge or faulty sensor | Replace filter first | ✅ |

🧠 16. Pro Tips to Prevent Future Issues

After years of maintaining my own Goodman unit, I’ve developed a list of “HVAC survival habits.”

-

Keep clearance clear. Maintain 2–3 feet around outdoor unit — no bushes, mulch, or fences.

-

Install a surge protector. Voltage spikes during storms can fry circuit boards.

-

Inspect insulation annually. Bare refrigerant lines waste efficiency.

-

Don’t constantly adjust thermostat. Every degree change forces more cycles.

-

Upgrade filters before heat season. Clean filters equal better heating performance.

-

Test system twice a year. Run it briefly in both modes before each season.

🧰 17. When DIY Goes Too Far: Common Mistakes to Avoid

It’s great to be hands-on — until it isn’t. Here are the most frequent homeowner missteps I’ve seen:

-

Overcharging refrigerant. Without proper gauges, you’ll damage the compressor.

-

Powering on during defrost. Never override a defrost cycle — it’s there for protection.

-

Ignoring airflow balance. Closing too many vents leads to coil freezing.

-

Skipping annual service. Even “maintenance-free” systems need inspection.

-

Using incorrect filters. High MERV filters restrict airflow in systems not designed for them.

Jake’s advice:

“If you’re not sure whether it’s safe to fix — don’t. But if you can change a filter or check a breaker, do it now, not later.”

🧮 18. The Cost of Ignoring Problems

Neglecting small issues doesn’t just hurt performance — it hits your wallet.

| Issue | Short-Term Effect | Long-Term Cost |

|---|---|---|

| Dirty filter | Higher energy bills | Blower motor burnout |

| Low refrigerant | Reduced cooling | Compressor failure ($1,000+) |

| Blocked airflow | Icing coils | System shutdown |

| Faulty thermostat | Inefficient cycling | Uneven comfort |

| Skipped maintenance | Gradual efficiency loss | $300–$600 more per year in energy costs |

A little attention now can extend your Goodman’s lifespan from 10 years to 15–20+.

🌍 19. Goodman’s Durability Advantage

Here’s why I stick with Goodman:

-

Heavy-duty compressor protection: Built-in overload and delay relay.

-

SmartFrame™ cabinet design: Reduces vibration, noise, and frost impact.

-

Advanced defrost logic: Minimizes unnecessary energy waste.

Even with occasional hiccups, Goodman systems are engineered for homeowners who want reliability without luxury-brand prices.

Just remember — even the best system needs airflow, maintenance, and a little attention to keep working flawlessly.

🏁 20. Jake’s Final Thoughts: Stay Calm, Stay Smart

“Heat pump issues always seem to happen on the hottest or coldest day of the year — but that doesn’t mean your system’s toast.”

In most cases, a Goodman heat pump not cooling or heating just needs:

-

A reset breaker.

-

A clean filter.

-

A thermostat check.

If you follow the steps in this guide, you’ll solve most issues yourself and know exactly when to call a pro for the rest.

The more you understand your Goodman system, the less you’ll stress when something goes wrong — and the more efficiently it’ll keep your home comfortable all year long.

In the next topic we will know more about: Maintenance Tips to Keep Your Goodman 3-Ton System Running Like New