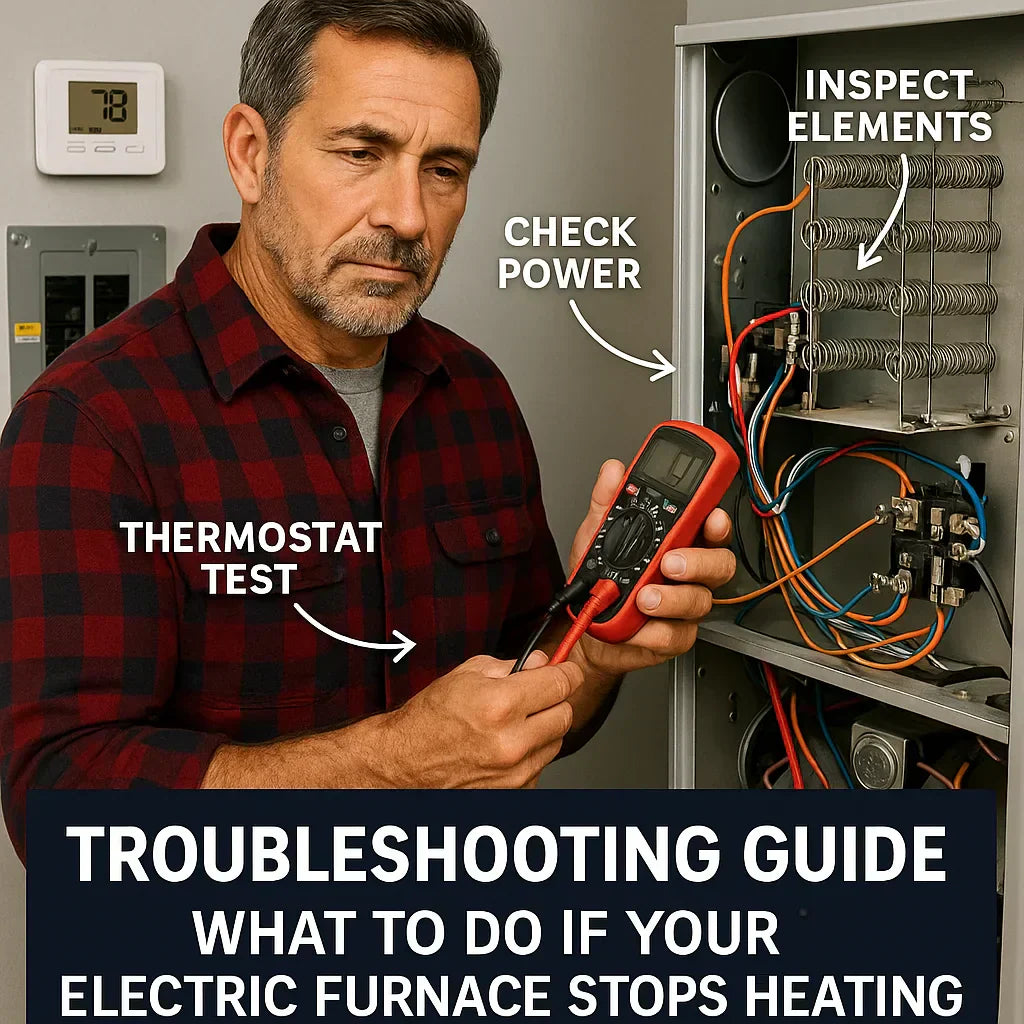

⚠️ 1. When the Heat Suddenly Stops

Mike Sanders woke up one January morning to an unexpected chill. The thermostat read 62°F — much lower than his usual 70. The fan was running, but the air blowing from his vents was cold.

“I knew something was wrong,” Mike recalls. “But instead of panicking, I grabbed my flashlight, turned off the breaker, and started investigating.”

If you’ve ever faced the same problem, don’t worry — you’re not alone. Electric furnaces are dependable, but like any machine, they can stop heating for several common reasons: tripped breakers, faulty thermostats, burnt-out elements, or clogged filters.

This guide walks you through how Mike troubleshoots his furnace step-by-step, so you can diagnose safely, fix small issues yourself, and know when to call a pro.

Before you begin, remember:

-

Safety first — always turn off power at the breaker before opening panels.

-

Have a voltage tester or multimeter handy.

-

If at any point you feel uncertain, stop and call a licensed technician.

Let’s get started.

⚙️ 2. How an Electric Furnace Heats — A Quick Refresher

To troubleshoot effectively, it helps to understand the basic process behind electric heat.

When your thermostat calls for heat, it sends a signal to your furnace’s sequencer (a type of relay). The sequencer then activates the heating elements — long resistance coils that glow red-hot as electricity flows through them.

Next, the blower motor turns on, pushing air over those elements and into your ducts.

Here’s the step-by-step chain of operation:

-

Thermostat detects temperature drop.

-

24V signal sent to sequencer (control board).

-

Heating elements activate in stages to prevent current spikes.

-

Blower motor engages to circulate warm air.

-

Limit switch monitors for overheating and shuts elements off if needed.

If any one of these parts fails, heat stops.

As Energy.gov explains, electric resistance systems are nearly 100% efficient at point of use — but only if all components are working together in sync.

🔌 3. Step 1 — Check the Power Supply

This is the simplest — and most common — culprit.

⚡ What Mike Does First:

-

Goes to the main electrical panel.

-

Looks for the double-pole breaker labeled “Furnace.”

-

If it’s tripped, he flips it fully OFF, then back ON.

Electric furnaces typically run on 240 volts. A tripped breaker often means one of two things:

-

A temporary power surge or overload.

-

A short circuit or failing component downstream.

If the breaker trips again immediately, don’t reset it repeatedly. That’s a sign of a deeper issue like a shorted heating element or loose connection.

Mike also checks the furnace disconnect switch — a smaller on/off box mounted near the unit. Many homeowners accidentally bump this switch during cleaning or storage.

The NFPA’s electrical safety guide emphasizes inspecting these connections before assuming a major failure.

🌡️ 4. Step 2 — Test the Thermostat

If your furnace has power but isn’t turning on, the thermostat could be to blame.

Mike’s system uses a smart Honeywell T9 thermostat, but even basic digital units can fail due to wiring, dead batteries, or misconfiguration.

🔍 Troubleshooting Steps:

-

Check the display — if blank, replace batteries or confirm it’s receiving 24V power from the furnace.

-

Ensure settings are correct — “HEAT” mode, fan on “AUTO,” and setpoint at least 3°F above room temperature.

-

Reset Wi-Fi or firmware for smart thermostats (can resolve communication glitches).

-

Remove the faceplate and inspect the wiring terminals (R, W, G, C).

-

Use a multimeter:

-

Between R (power) and W (heat signal), test for 24V.

-

No voltage? The thermostat isn’t sending a signal.

-

If voltage is present, the furnace should engage the sequencer — meaning the problem lies inside the unit.

The Energy Star Smart Thermostat Guide recommends recalibrating and updating software regularly to prevent miscommunication between smart thermostats and HVAC systems.

“Half the time, it’s not the furnace — it’s the thermostat,” Mike says. “One loose wire or setting can stop everything.”

🧯 5. Step 3 — Inspect Fuses, Limit Switches, and Sequencer

If your furnace has power and the thermostat is sending a signal, but still no heat, the issue may be inside the cabinet.

⚠️ Safety First:

Always shut off the main power breaker before removing access panels.

Inside the furnace, Mike checks three key safety components:

1. Fuses

Some electric furnaces have inline fuses protecting the transformer or sequencer circuit. A blown fuse can cut control power. He removes and tests each with a multimeter set to continuity mode — if it reads “open,” the fuse is bad.

2. Limit Switch

This safety sensor detects overheating and cuts power to the elements. If it’s faulty or dirty, it can open prematurely.

Mike locates it near the blower housing, removes dust gently, and checks continuity.

3. Sequencer

This is the “traffic cop” of electric heat. It turns heating elements on one at a time to prevent overloading.

If the sequencer fails, no elements activate, even though the blower may still run.

Symptoms of a bad sequencer:

-

Furnace fan runs, but air is cold.

-

No visible coil heating.

-

No 240V signal to elements.

Replacement costs range from $75–$200, depending on model.

Family Handyman offers a great visual breakdown of where to find limit switches and sequencers inside typical furnaces.

🔥 6. Step 4 — Check the Heating Elements

If everything else checks out, the issue may be a burnt-out heating element.

Each element works like a giant toaster coil. Over time, cycles of expansion and contraction can cause fractures or shorts to ground.

🧰 Mike’s Method:

-

Turn off power at breaker.

-

Remove the front panel to expose elements.

-

Disconnect one wire from each terminal to isolate the coil.

-

Set his multimeter to ohms and measure resistance:

-

A good element typically shows 10–15 ohms.

-

Infinite resistance means the coil is broken.

-

Replacing an element is straightforward for DIYers comfortable with wiring. Most cost $50–$150 and slide into the housing like an oven element.

Home Depot’s furnace element guide includes visuals and model-matching charts for replacement parts.

Mike once replaced a single failed element in under an hour — saving over $250 compared to a service call.

“It’s like changing a light bulb,” he says. “Once you’ve seen it done, it’s not intimidating.”

🌬️ 7. Step 5 — Inspect the Blower Motor and Airflow

If your heating elements work but warm air isn’t circulating, the blower could be at fault.

🔎 Mike Checks:

-

Fan setting — “AUTO” instead of “ON.”

-

Motor spin — Should move freely by hand (no scraping).

-

Capacitor — A weak capacitor prevents the blower from starting.

He uses his multimeter’s microfarad function to test the capacitor against its rated value (usually 5–15 µF). If it’s more than 10% off, he replaces it — capacitors cost about $20–$50.

He also vacuums the blower blades and lubricates bearings if applicable. Dust buildup can cause imbalance and vibration, shortening motor life.

If the blower hums but won’t start, the motor windings may have failed — time to call an HVAC pro.

Energy.gov’s HVAC maintenance page recommends blower inspection every heating season for optimal airflow and efficiency.

🧰 8. Step 6 — Look for Safety Switch or Door Interlock Problems

It sounds simple, but Mike once spent 30 minutes diagnosing a “dead furnace” before realizing the door safety switch wasn’t fully depressed.

These switches cut power when the panel is open. If the door isn’t aligned or snapped shut correctly, the furnace won’t run.

To check:

-

Open and reclose the furnace access panel firmly.

-

Inspect the switch for dirt or misalignment.

-

Test continuity across terminals with the door pressed in.

If the switch reads open when pressed, it’s faulty — a quick $15–$25 replacement part.

🧊 9. Step 7 — Rule Out Duct or Airflow Issues

Sometimes the furnace is working fine — but your home doesn’t feel warm because of airflow restrictions.

🕵️ Mike Looks For:

-

Blocked or closed supply vents.

-

Collapsed flex ducts (especially in attics or crawlspaces).

-

Leaky return ducts sucking cold air from unconditioned spaces.

He also replaces his filter again if it’s even slightly dirty. Restricted airflow can cause the limit switch to trip, shutting off heat cycles prematurely.

The Energy Star Duct Sealing Guide notes that sealing and insulating ducts can improve efficiency and comfort by up to 20%.

“I learned that sometimes, the ‘no heat’ problem isn’t inside the furnace at all,” Mike says. “It’s in the airflow.”

🧠 10. When to Call a Professional

There’s a limit to safe DIY. Mike’s rule: “If it involves live voltage, high amperage, or wiring replacement, I call a pro.”

📞 Call an HVAC technician if:

-

The breaker trips repeatedly.

-

Wires show burn marks or melted insulation.

-

You smell electrical burning.

-

The blower runs constantly but never heats.

-

Voltage testing feels beyond your comfort level.

Professional repairs for electric furnaces average $150–$300, according to Angi. Serious repairs like replacing sequencers, motors, or control boards can range higher — but catching problems early often prevents major costs.

💬 11. Mike’s “Don’t Panic” Troubleshooting Checklist

When his furnace stops heating, Mike follows this order every time:

| Symptom | Likely Cause | Mike’s Fix |

|---|---|---|

| No power at all | Tripped breaker or blown fuse | Reset breaker, test fuses |

| Fan runs but no heat | Bad sequencer or burnt element | Test continuity, replace part |

| Furnace starts but shuts off quickly | Clogged filter or tripped limit switch | Replace filter, reset limit switch |

| Thermostat blank | Dead batteries or loose wiring | Replace batteries, tighten connections |

| Uneven heating | Blocked ducts or poor airflow | Clear vents, inspect ducts |

“Don’t skip steps,” Mike advises. “Start simple — filters, breakers, thermostat — then move deeper. Nine times out of ten, the fix is right in front of you.”

🧾 12. Preventing Future Heating Failures

After years of experience, Mike’s learned that most furnace problems are preventable.

🧭 His Preventive Maintenance Tips:

-

Replace filters every 60–90 days.

-

Keep return vents clear from obstructions.

-

Vacuum furnace cabinet twice a year.

-

Tighten wiring terminals annually (with power off).

-

Add a surge protector to safeguard electronic components.

-

Schedule a yearly tune-up for amperage and airflow testing.

-

Log maintenance tasks in a simple notebook.

According to Energy.gov, consistent maintenance can reduce furnace failures by up to 75% and extend lifespan by a decade.

Mike also uses his thermostat’s runtime reports to track performance trends — a steady rise in runtime may indicate reduced efficiency or airflow issues long before a total shutdown.

💡 13. When It’s Time to Replace Instead of Repair

Sometimes, even the best troubleshooting leads to one conclusion: it’s time for a new furnace.

Signs It’s Nearing the End:

-

Age over 20–25 years.

-

Frequent part replacements.

-

Rising energy bills with the same usage.

-

Noisy or vibrating blower.

-

Uneven or slow heating despite clean components.

Modern electric furnaces offer ECM blower motors, smart diagnostics, and compatibility with heat pumps — making them quieter, more efficient, and easier to maintain than older models.

Mike replaced his 15-year-old unit when repairs started stacking up, and he immediately noticed smoother performance and lower runtime.

“Replacing was cheaper in the long run than nursing it along,” he admits. “And the peace of mind is priceless.”

🧩 14. Final Takeaway — Knowledge Is Comfort

Mike’s troubleshooting philosophy boils down to one principle: understanding your system saves money and stress.

By following a methodical checklist, using a multimeter responsibly, and learning how each part functions, homeowners can fix small issues confidently — or at least narrow down the cause before calling a technician.

🧠 Mike’s Final Advice:

-

Start simple: Check breakers, filters, and thermostat first.

-

Stay safe: Turn off power before touching anything.

-

Keep tools handy: A flashlight, screwdriver, and meter are your best friends.

-

Don’t guess — test: Use a multimeter to confirm faults.

-

Learn your model: Keep your manual bookmarked or saved digitally.

“Troubleshooting isn’t just fixing something — it’s learning something. Every time you open that panel, you get better at understanding how your home works.”

If your furnace has stopped heating, don’t panic. With Mike’s approach, you’ll either get your heat back quickly or know exactly what to tell your technician — saving time and money while staying warm through the coldest months.

In the next topic we will know more about: Cold-Climate Performance: Can Electric Furnaces Handle Harsh Winters?