As the HVAC industry navigates the transition to low-GWP refrigerants, many manufacturers and contractors are grappling with the operational reality of supporting both R-32 and R-454B systems. While each refrigerant has its technical merits, maintaining infrastructure and service models for two separate A2L refrigerants creates costly inefficiencies that ripple throughout the supply chain. In this guide, we break down the real-world financial and logistical burden of a dual-refrigerant approach—and why streamlining around one option, like R-32, is a smarter long-term move.

Dual Refrigerant Support: What It Really Entails

The decision to support multiple refrigerants isn’t just about offering consumer choice—it requires building parallel tracks for:

-

Inventory and storage

-

Equipment calibration and servicing tools

-

Technical training and certification

-

Regulatory documentation and safety protocols

According to the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), the refrigerant transition is already placing strain on manufacturer and distributor operations. Introducing multiple A2L refrigerants compounds that challenge.

1. Inventory and Supply Chain Strain

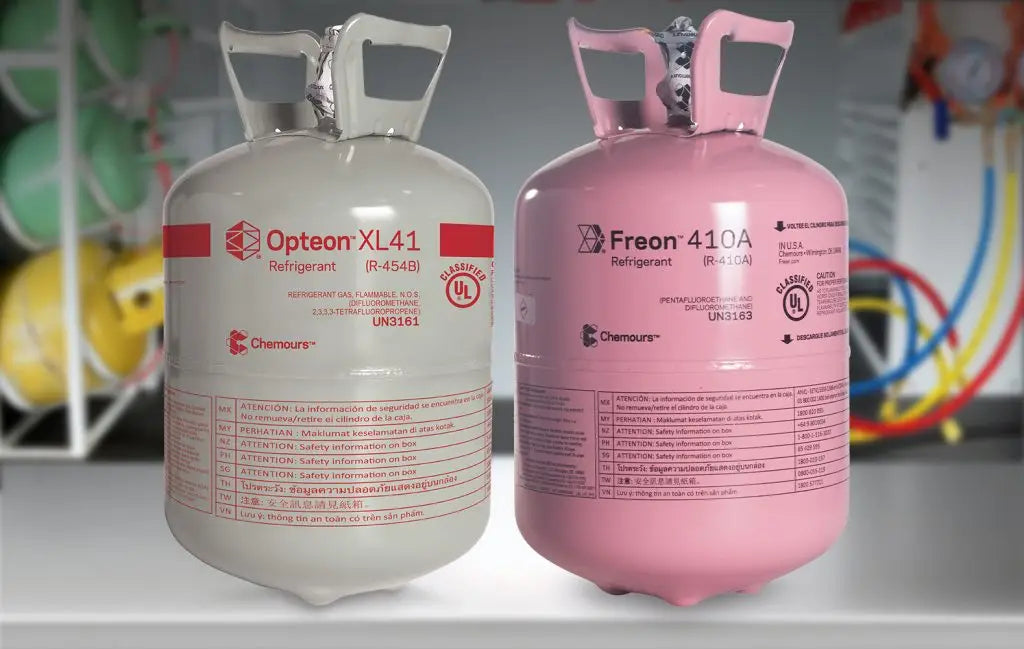

Supporting both R-32 and R-454B means doubling up on:

-

Refrigerant cylinders

-

Service valves, compressors, and metering devices tailored to each gas

-

Leak detection systems calibrated to differing flammability and chemical profiles

This increases warehouse space demands and introduces a higher risk of mislabeling, stocking errors, or shortages during peak season. For HVAC distributors and contractors, it becomes a question of cost per square foot vs. refrigerant return.

2. Increased Training Requirements

Technicians must be trained on the handling, installation, and recovery procedures for both refrigerants:

-

R-32 is a single-component refrigerant with unique pressure behavior and leak response protocols.

-

R-454B, a blend, introduces additional considerations in terms of component fractionation during leaks and recharge cycles.

This can result in duplicated or extended technician training hours, often requiring updates to tools and certifications. Manufacturers also incur costs for producing service manuals, documentation, and safety standards for both refrigerants.

3. Equipment and Tooling Duplication

Because R-32 and R-454B differ in pressure and composition, service tools like recovery machines, vacuum pumps, gauges, and leak detectors may not be interchangeable. Supporting both increases capital equipment investments across:

-

Manufacturer production lines

-

Contractor service fleets

-

In-house technical training labs

In effect, businesses have to choose between absorbing higher upfront costs or sacrificing service breadth.

4. Safety and Compliance Management

While both R-32 and R-454B are classified as A2L (mildly flammable), they present different handling risks. Maintaining regulatory compliance for both requires redundant safety training and liability management.

Contractors must develop and maintain two sets of hazard communication plans, refrigerant storage procedures, and installation guidelines—all of which require third-party auditing or review to meet compliance standards like those outlined by ASHRAE.

5. Cost Burden Passed to Homeowners

The end result of this complexity is clear: increased costs for the consumer. Whether it’s higher installation fees, longer service times, or confusion over which refrigerant is being installed, homeowners pay for the inefficiencies built into a split-refrigerant system.

In contrast, aligning around a single refrigerant streamlines operations and simplifies purchasing decisions. Many contractors and wholesalers are already signaling preference for R-32 due to its availability, service simplicity, and global adoption.

Conclusion: Efficiency Demands Consolidation

As we transition to low-GWP refrigerants, supporting both R-32 and R-454B may seem like a hedge—but in practice, it's a liability. The HVAC industry thrives on scalable, standardized systems. Streamlining to a single refrigerant like R-32 not only saves money but also reduces errors, accelerates training, and improves service outcomes.

For a deeper comparison between the two refrigerants, read our full guide on R-32 vs. R-454B.