As HVAC regulations evolve and refrigerant landscapes shift, contractors are at the forefront of implementing change. With more manufacturers and governments endorsing R-32 as the next-generation A2L refrigerant, it’s essential for HVAC professionals to understand what’s required to service, install, and transition to R-32 systems. This guide outlines everything contractors need to know about transitioning to R-32 equipment, from safety practices to tools and training.

Why R-32?

R-32 is a low-GWP refrigerant (675) and part of the A2L (mildly flammable) class. It offers:

-

Higher efficiency than R-410A and R-454B

-

Single-component composition, simplifying charging and servicing

-

Widespread adoption across Europe, Asia, and North America

Contractors who adopt R-32 early can gain a competitive edge and streamline training and inventory across equipment lines.

Training & Certification

While R-32 is easier to handle than blended refrigerants like R-454B, proper training is still essential. Contractors should:

-

Complete A2L refrigerant certification (where required by state or local codes)

-

Review EPA and AHRI safety guidance on low-flammability refrigerants

-

Participate in programs such as the ESCO Group R-32 Technician Training

Technicians should be familiar with:

-

Leak detection procedures

-

Safe ventilation practices

-

Proper labeling and system pressurization

Tools & Equipment for R-32

Fortunately, many tools used for R-410A can also support R-32 with minimal updates. However, contractors should confirm the following:

✅ Required Tools

-

Compatible manifold gauges rated for R-32 pressure

-

Recovery machines rated for A2L refrigerants

-

Leak detectors calibrated for hydrofluorocarbons (HFCs)

-

Vacuum pumps with spark-free motors

-

Properly rated hoses and couplings (UL 1963)

🔧 Safety Gear

-

Flame-proof gloves and eye protection

-

Ventilation fans for enclosed work areas

Installation Guidelines

R-32 system installation is similar to R-410A in terms of layout, but with enhanced safety precautions:

-

Ensure adequate ventilation during refrigerant handling

-

Avoid open flames or ignition sources during service

-

Use non-sparking tools in areas of possible refrigerant accumulation

Many OEMs provide specific R-32 installation guidelines with their equipment—review them thoroughly before work begins.

Transitioning Inventory & Customer Messaging

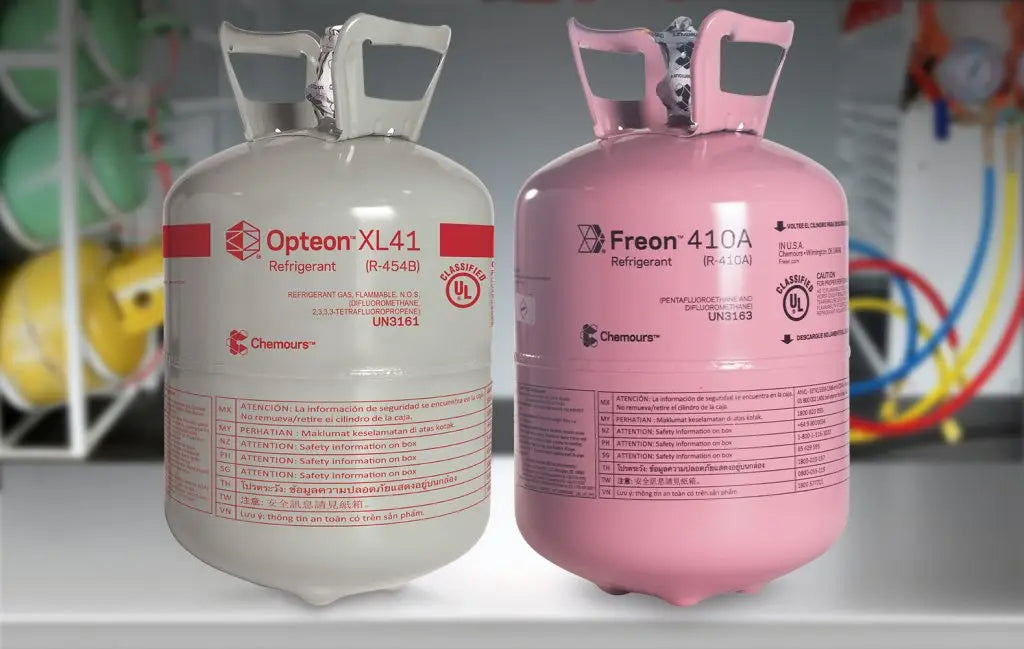

If you’re currently installing or servicing R-410A or R-454B systems:

-

Start transitioning inventory toward R-32-compatible parts and units

-

Train staff on the serviceability advantages of R-32 over blends

-

Update customer-facing documentation to include R-32 education

Position R-32 as a long-term investment for customers—emphasize its energy savings, widespread availability, and service simplicity.

Case Study: Early Adopters Share the Benefits

Contractors in regions like California and Florida, where state-led HFC phasedown rules have accelerated R-32 adoption, report:

-

Fewer service callbacks due to chemical stability

-

Simplified technician onboarding

-

Improved profit margins thanks to reduced inventory and faster installation times

As detailed in our global R-32 adoption report, these real-world outcomes align with the strategic shift to a single, proven refrigerant.

Final Thoughts

The transition to R-32 is not just a regulatory shift—it’s a business opportunity. Contractors who invest in training, safety, and streamlined operations now will gain long-term efficiency and market leadership.

For a complete overview of how R-32 compares to alternatives, check out our full refrigerant comparison.