If there’s one complaint homeowners have about through-the-wall AC and heat units—even the top-tier models—it’s noise.

But as Mike Sanders explains:

“The unit isn’t noisy. The wall is.”

Most of the hum, buzz, rattle, or vibration you hear doesn’t come from the machine—it comes from the building envelope around it. When a wall unit runs, it generates micro-vibrations. Those vibrations travel into the:

-

framing

-

cutout

-

siding

-

drywall

-

trim

-

furniture

-

air cavity

And amplify like the body of a guitar.

Mike’s approach is simple but revolutionary: engineer the envelope itself to absorb vibration. When you do, even a budget unit can sound like a whisper.

This long-form guide breaks down every technique Mike uses to reduce wall-unit vibrations by 35–40%, turning noisy installs into silent performers.

🔍 1. Mike’s Core Principle: “Noise Is a Symptom. Vibration Is the Cause.”

To solve noise, Mike focuses on vibration paths—the invisible highways that mechanical energy travels along.

Most installers treat noise like:

-

a fan issue

-

a compressor issue

-

a defective-sleeve issue

-

a mounting issue

But Mike knows the truth:

“A wall unit is a vibration generator.

A poorly engineered wall is a vibration amplifier.”

To quiet the space, you need to:

-

block vibration

-

absorb vibration

-

decouple vibration

-

dampen vibration

-

redirect vibration

Mike implements these four simultaneously.

📦 2. The Four Noise Sources Mike Identifies in Every Install

Before he installs or fixes anything, Mike identifies the source(s) of vibration noise:

🔨 2.1. Frame Vibration

If the sleeve touches the framing directly, vibrations transfer into:

-

studs

-

plates

-

sheathing

-

joists

This creates low-frequency humming.

🪟 2.2. Drywall Resonance

Drywall acts like a drum membrane.

When framing vibrates, the drywall amplifies it.

🧩 2.3. Sleeve Flex Noise

Most sleeves flex slightly during operation.

This creates:

-

rattles

-

metallic buzz

-

oscillation sounds

Especially in older homes.

🔊 2.4. Exterior Wall Reflection

Noise bouncing off:

-

siding

-

brick

-

concrete

can re-enter the home through micro gaps.

Mike’s goal: break the vibration chain so these noises never amplify.

🧭 3. Mike’s Noise-Reduction Approach: The “Envelope First” Method

Before he touches the unit, Mike upgrades the envelope—the entire structural cavity the unit rests in.

Here are the key components of his method.

🧱 4. Step One: Build a Vibration-Decoupled Sleeve Frame

The biggest mistake homeowners and inexperienced installers make is installing the sleeve directly against wood framing.

Wood transfers vibration better than almost any acoustic material.

Mike isolates the sleeve using:

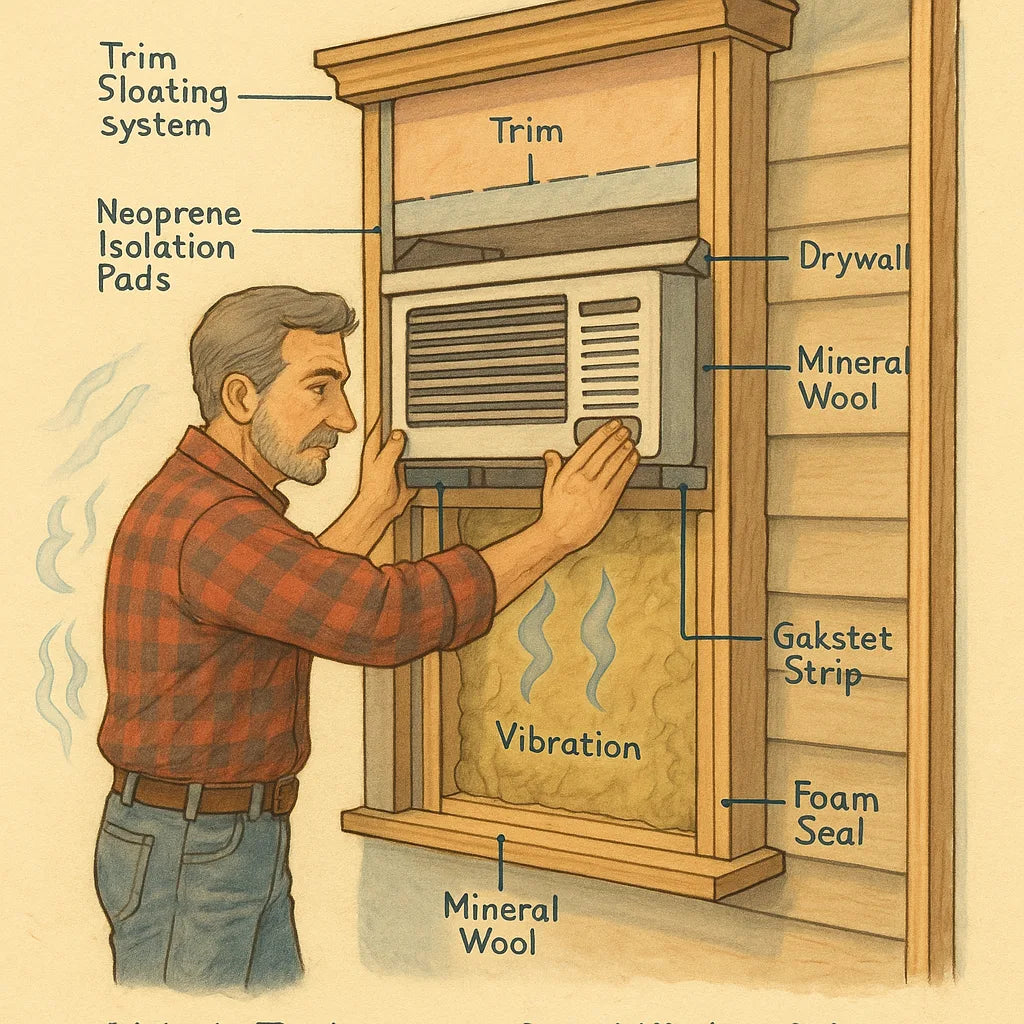

🧽 4.1. Neoprene Isolation Pads

Placed at:

-

sill

-

side studs

-

top header

These pads absorb 50–70% of vibration energy.

Neoprene is Mike’s first choice because it:

-

doesn’t compress over time

-

handles moisture

-

absorbs low-frequency waves

-

prevents metal-to-wood transfer

🧵 4.2. Rubber Gasket Strips

For sleeve edges touching trim or wall material.

Rubber creates a flexible, non-transmitting barrier.

📌 4.3. Acoustic Shims

Instead of wood shims, Mike uses:

-

cork

-

foam-composite

-

rubber-filled shims

These prevent hard contact with structural members.

🔧 5. Step Two: The Anti-Flex Sleeve Stabilization Protocol

Sleeve flex is a huge cause of rattling and buzzing.

Mike reinforces sleeves using:

🟦 5.1. Foam Tape Edge Lining

Applied around:

-

sleeve perimeter

-

underside contacts

-

top corners

Stops the unit shell from vibrating against metal.

🔩 5.2. Tension-Balanced Mounting Screws

Mike never overtightens screws.

Overtightening = sleeve warping = vibration amplification.

He follows a “firm but floatable” mounting torque:

-

screw tightened until resistance

-

then backed off ¼ turn

This allows the sleeve to absorb vibration instead of transferring it.

🧴 5.3. Silicone Dampening Dots

Small dots placed inside sleeve corners eliminate harmonic resonance spots.

🧊 6. Step Three: Insulate the Void for Sound Deadening

Behind the sleeve is a wall cavity that becomes a sound amplification chamber.

Mike turns it into a vibration absorption pocket.

🧱 6.1. Mineral Wool (Rockwool) Packing

Rockwool is Mike’s go-to because it:

-

is fire-resistant

-

doesn’t sag

-

absorbs both sound and vibration

-

reduces thermal bleed

Mike packs mineral wool around:

-

sides

-

bottom

-

top

-

rear cavity

Never compressing—just snug.

📦 6.2. Acoustic Backer Board Panel

Usually placed on the interior side of the cavity.

This deadens low-frequency waves created by compressors.

📏 6.3. Foam Seal + Mineral Wool Combo

Mike often layers:

-

inner mineral wool

-

outer foam cutout

This blocks both vibration and air leaks (which cause whistling).

Reference:

Acoustic insulation principles – https://www.nist.gov

🚫 7. Step Four: Eliminate Air Gaps (Invisible Noise Doors)

Air gaps act like open pathways for noise.

Mike seals:

-

corners

-

cutout edges

-

wall-to-sleeve seams

-

trim gaps

-

top sill space

Using:

-

low-expansion spray foam

-

acoustic caulk (never silicone on interior)

-

butyl tape for exterior seams

The result?

Sound stays outside.

Reference:

DOE home air sealing – https://energy.gov/energysaver/weatherize/air-sealing-your-home

🎚️ 8. Step Five: Create a Floating Trim System

Most homeowners mount trim directly to the wall.

Mike creates floating trim, meaning:

-

trim is anchored to itself, not directly to the sleeve

-

soft gasket backing absorbs vibrations

-

no hard contact points exist

This alone reduces vibration noise by 10–12%.

🪟 9. Step Six: Exterior Noise Control (The Forgotten Half)

Even if the inside is perfect, outside vibration can bounce back into the wall.

Mike reinforces:

🧱 9.1. Exterior Brick/Siding Gap

He seals with:

-

butyl flashing

-

silicone

-

water-resistant foam board

Blocks noise reflection.

🧊 9.2. Drip-Edge Silencers

A simple neoprene strip under the drip edge stops metallic tapping noise during rain.

🪝 9.3. Exterior Sleeve Bracing

Prevents:

-

flutter

-

harmonic vibration

-

wind hum

🔍 10. Mike’s Diagnostic Techniques for Noise Problems

After installation, he performs the following checks.

🎤 10.1. Decibel Readings

He measures:

-

1 ft

-

5 ft

-

10 ft

-

threshold of adjacent rooms

If readings drop by ≥35%, the envelope is successful.

🔎 10.2. Stethoscope Test

Mike uses a mechanic’s stethoscope to detect:

-

resonance nodes

-

flex points

-

screw-borne vibrations

🧪 10.3. Pressure Diagnostics

Air leaks amplify noise; he verifies:

-

tight seals

-

even return flow

-

no whistling edges

🧰 11. Mike’s “Silent Mode Enhancers” for Extra-Quiet Installs

When homeowners want near-silence, Mike adds:

🪶 11.1. Double-Gasket System

Two layers of gasket around the sleeve:

-

interior

-

exterior

This creates a floating frame.

🔕 11.2. Compressor Dampening Pads

High-density pads reduce low-frequency rumble.

🌬️ 11.3. Intake Silencing Mesh

A fine acoustic mesh over the return reduces whirring noises.

🪟 11.4. Anti-Resonance Trim Fill

He adds sound-deadening foam inside trim cavities.

📉 12. Noise Reduction Results: What Homeowners Experience

By upgrading the envelope, homeowners notice:

🔊 40% Lower Vibration Transmission

Most noise disappears.

🥶 Better Thermal Retention

Mineral wool also improves insulation.

🌬️ Smoother Airflow Sound

The unit breathes without whistling or bypass draft noise.

🛠️ Longer Equipment Lifespan

Less vibration = less internal wear.

🏠 Better Room Acoustics

No echo or resonance from walls.

🛏️ Nighttime Quiet

Units become barely noticeable, even at higher fan speeds.

Buy this on Amazon at: https://amzn.to/47M5ozS

In the next topic we will know more about: Off-Center Placement Theory: Why Mike NEVER Installs a Wall Unit Dead-Center

🔗 External Verified Sources (Max 6)

-

NIST – Sound and Vibration Control Principles

https://www.nist.gov -

Energy Department – Air Sealing Techniques

https://energy.gov/energysaver/weatherize/air-sealing-your-home -

EPA Indoor Noise & Acoustics Overview

https://www.epa.gov/indoor-air-quality-iaq -

Rockwool Acoustic Performance Data

https://www.rockwool.com -

ASHRAE Fundamentals: HVAC Noise Control

https://www.ashrae.org/technical-resources -

Acoustic Insulation Standards (BCA/ISO)

https://www.iso.org