🌱 Introduction: Quiet Comfort Isn’t Luck — It’s Geometry

Most homeowners think HVAC noise comes from “a loud unit,” “old equipment,” or “bad insulation.” But Savvy is here to spill the green truth:

➡️ HVAC noise is a design problem, not a hardware problem.

➡️ The geometry of airflow — angles, distances, openings, and pathways — determines 80% of the noise you hear.

➡️ Quiet HVAC is engineered long before the system is ever powered on.

From grille placement to vent sizing to air handler location, the hidden geometry of airflow determines whether your home sounds like a peaceful eco-retreat…

or a rumbling mechanical closet.

Today, you’ll learn how to design whisper-quiet HVAC systems using the same principles that architects, acousticians, and high-end builders rely on.

Let’s quiet things down — sustainably.

🧠 1. The Three Types of HVAC Noise (And Why Geometry Controls All of Them)

Before we dive into layout strategies, you need to understand the noise sources.

🔊 1.1 Airborne Noise (Whooshing, Whistling, Rushing Air)

Caused by:

-

high air velocity

-

undersized grilles

-

restrictive filters

-

sharp duct bends

-

vent placement near obstacles

This is the noise most homeowners notice first.

⚙️ 1.2 Mechanical Noise (Vibration, Humming, Buzzing)

Generated by:

-

air handler

-

blower motor

-

refrigerant flow

-

compressor operation

Proper placement and isolation dramatically reduce this noise.

🧱 1.3 Structural Noise (Noise Transmitted Through Walls/Floors)

Caused by:

-

ducts touching framing

-

air handler sitting on wood

-

uninsulated metal ducts

-

vibrations traveling through joists

Quiet HVAC is as much about decoupling as airflow.

🌬️ 2. Air Velocity — The #1 Factor in Perceived HVAC Loudness

Every grille, vent, and duct should be designed around velocity, not tonnage.

📏 2.1 Ideal Air Velocity Targets

| Component | Ideal Velocity | Noise Level |

|---|---|---|

| Return grille | 250–350 FPM | Whisper-quiet |

| Supply grille | 300–450 FPM | Balanced + quiet |

| Main trunk duct | 700–900 FPM | Quiet & efficient |

| Branch ducts | 500–700 FPM | Prevents whistle |

ASHRAE airflow recommendations:

🔗 https://www.ashrae.org/technical-resources

When you exceed these velocities…

➡️ grilles whistle

➡️ vents roar

➡️ rooms whoosh

➡️ system becomes noticeably loud

The fix is geometric:

-

larger ducts

-

wider grilles

-

gentler turns

-

slower blower speeds

Quiet = wide, slow, smooth airflow.

🪟 3. Grille & Vent Geometry — How Shape, Size & Placement Determine Noise

Let’s talk grilles, because Savvy knows:

➡️ Grilles are the speakers of your HVAC system.

They amplify whatever airflow you send through them.

🔲 3.1 Rule #1 — Bigger Grilles = Quieter System

A grille that is too small forces air to accelerate — instantly creating noise.

Minimum grille free area:

2 sq inches per 1 CFM of airflow

Example:

If a room needs 120 CFM → grille free area = 240 sq in → grille size ~14×20 or larger.

🎯 3.2 Rule #2 — Avoid High-Velocity Supply Grilles Near Seating

Supply grilles should NEVER be placed:

-

directly over beds

-

over couches

-

over desks

-

in spots where air blows at the face

Not for comfort — for noise.

🌀 3.3 Rule #3 — Use Long-Throw Grilles Only When Needed

Long-throw grilles send air further, but at higher velocity = more noise.

Use them only for:

-

large rooms

-

open floor plans

-

high ceilings

🧩 3.4 Rule #4 — Use Opposing Blade or Curved Blade Grilles for Quiet Flow

Curved blades break up turbulence and distribute air quietly.

Opposing blades help reduce throw velocity while improving mixing.

🎨 3.5 Rule #5 — Angling Matters

Supplies should:

-

aim upward or across rooms

-

NEVER downward

-

avoid blowing against nearby walls

A vent blowing directly at a wall creates reflection noise.

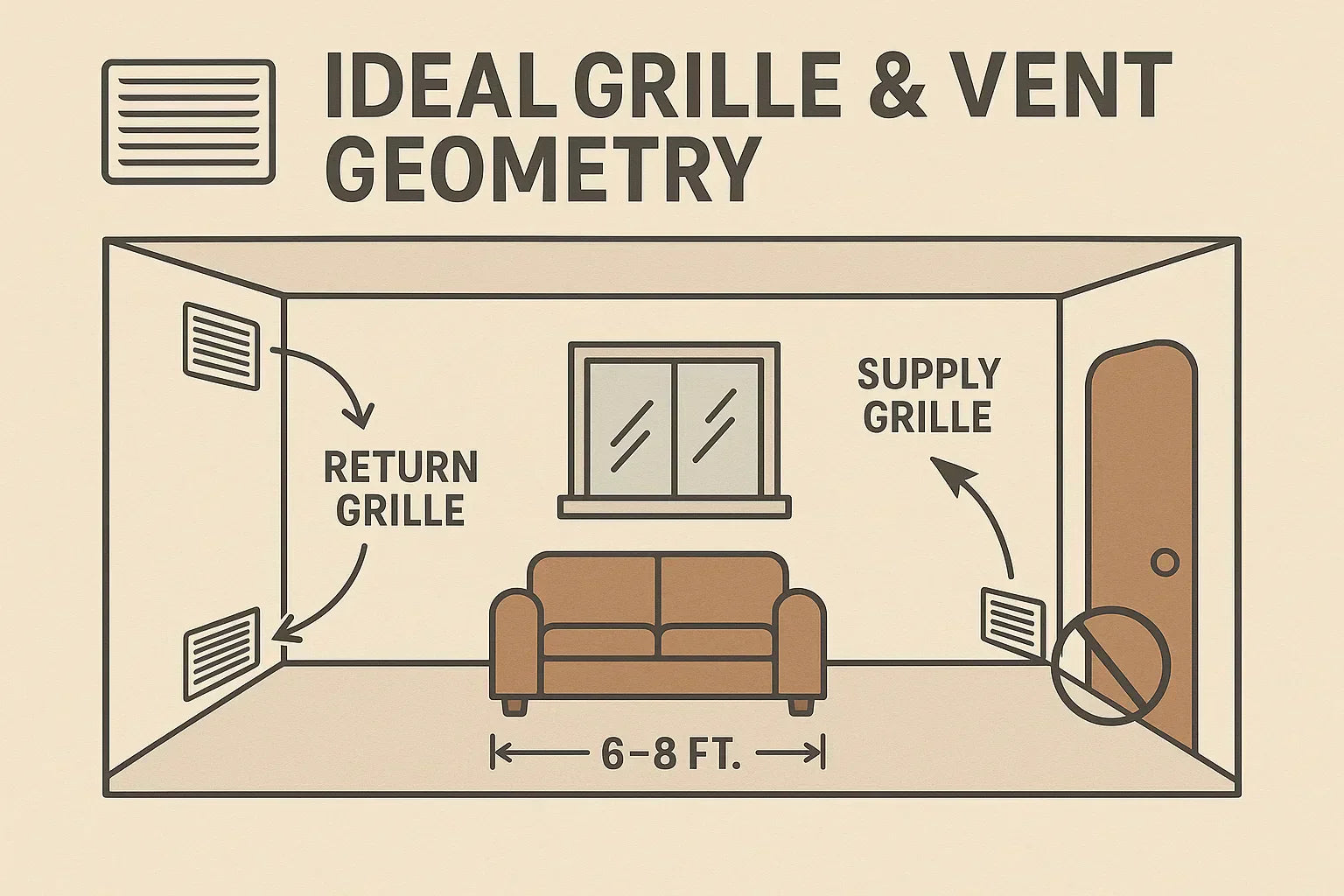

📍 4. Vent Placement — The Geometry of Where Noise Begins (and Ends)

Placement determines airflow patterns, which determines noise.

🧱 4.1 Supply Vent Placement Principles

Supplies should be:

✔️ Opposing heat gain

Placed under windows or on exterior walls.

✔️ Away from seating zones

At least 6–8 feet from common sitting areas.

✔️ Positioned for long mixing paths

Angled toward the center of room, not corners.

✔️ NOT behind doors

A vent restricted by a door produces pressure spikes → whistle.

✔️ NOT near ceiling edges

Creates turbulence as air hugs the wall.

🔁 4.2 Return Vent Placement Principles

Returns should be:

✔️ On interior walls

Exterior walls cause condensation issues.

✔️ High on the wall

Hot air = loud air if trapped at ceiling.

✔️ Away from supply vents

Never place supply directly across from a return (short cycling → loud airflow).

✔️ In hallways or central zones

Captures air from multiple rooms quietly.

EPA IAQ guidance on return pathways:

🔗 https://www.epa.gov/indoor-air-quality-iaq

🧊 5. Air Handler Placement — The Silent Heartbeat of Quiet Homes

Where you put the air handler determines:

-

vibration noise

-

duct pressure noise

-

refrigerant line noise

-

resonance

-

blower sound transfer

🚪 5.1 NEVER Place Air Handlers in These Locations

❌ Bedroom closets

The #1 source of HVAC noise complaints.

❌ Shared walls with bedrooms

Even with insulation, mechanical noise transfers.

❌ Unconditioned attics in hot climates

Heat amplifies blower noise.

❌ Under stairwells

Creates resonance chambers.

🏡 5.2 Best Locations for Quiet Operation

✔️ Utility closets with insulated walls

✔️ Conditioned basements

✔️ Encapsulated attics

✔️ Garage mechanical rooms (in non-humid climates)

✔️ Dedicated mechanical rooms

Isolate the sound → isolate the equipment.

🔧 5.3 Mounting Geometry — The Silent Engineering Trick

To eliminate vibration noise:

-

mount air handler on anti-vibration brackets

-

create isolation gap between platform and structure

-

install rubber standoffs for blowers

-

use vibration-absorbing pads under unit

ASHRAE vibration control guidance:

🔗 https://www.ashrae.org/technical-resources

🌀 6. Duct Layout Geometry — The Hidden Mathematics of Quiet Airflow

Now we get to the heart of geometric engineering.

🧭 6.1 Rule #1 — Use Long-Radius Elbows

Sharp 90° bends cause:

-

turbulence

-

velocity spikes

-

whistling

-

static pressure increases

-

blower strain

Use long-radius 90° elbows or two 45° elbows.

📏 6.2 Rule #2 — Avoid Sudden Transitions

Going from a 12" duct to a 6" duct instantly doubles velocity.

The noise is loud and unpredictable.

Use:

-

tapered transitions

-

smooth metal connectors

-

gently reducing adapters

🌬️ 6.3 Rule #3 — Oversize the Main Trunk for Quiet

Quiet trunk sizing:

-

4-ton system → 16–18" trunk

-

3-ton system → 14–16" trunk

-

2-ton system → 12–14" trunk

Bigger trunks = slower air = quiet.

DOE duct noise research:

🔗 https://www.energy.gov/energysaver/energy-saver

🎻 7. Sound Dampening — The Acoustic Layer Most Homes Are Missing

Even perfect geometry can benefit from noise dampening.

🧼 7.1 Duct Liner

Internal duct liner absorbs:

-

high-frequency fan noise

-

turbulence

-

vibrations

Use in:

-

metal trunks

-

return ducts

-

mechanical closets

🧵 7.2 Acoustic Closet Insulation

Insulate:

-

walls

-

floors

-

ceilings

-

door panels

Use mineral wool for best performance.

🧰 7.3 Flexible Couplings

Breaks vibration transmission between:

-

blower

-

ductwork

-

air handler

-

home framing

🌿 8. Smart Thermostats & Blower Settings — The Sound Control You Didn’t Know You Had

ECM blowers + smart thermostats = hidden quiet mode.

✔️ Slow ramp-up

Reduces initial blast noise.

✔️ Quiet mode

Lower maximum velocity.

✔️ Circulation mode

Keeps system quieter during mixing cycles.

✔️ Longer runtime at lower speed

Quieter and more efficient.

(Ecobee recommended)

🔗 https://www.ecobee.com/en-us/

🧩 9. How R-32 Systems Fit In — The Eco-Quiet Advantage

R-32 refrigerant systems run:

-

cooler discharge temperatures

-

lower noise scroll compressors

-

higher efficiency at lower airflow

Meaning:

➡️ R-32 systems are naturally quieter — when designed correctly.

EPA R-32 guidance:

🔗 https://www.epa.gov/snap

But only if your geometry supports quiet airflow.

🧡 10. Savvy’s “Quiet Geometry Blueprint” (Copy This)

✔️ Oversize grilles & returns

✔️ Keep air velocity under 450 FPM

✔️ Locate returns away from supplies

✔️ Place supplies on exterior walls

✔️ Use long-radius elbow ducts

✔️ Never place air handlers near bedrooms

✔️ Mount equipment on vibration-isolation pads

✔️ Use lined ductwork for returns

✔️ Use smart thermostat quiet modes

✔️ Keep static pressure < 0.5 in WC

You follow this?

You get a whisper-quiet home.

🌎 Conclusion: Quiet HVAC Isn’t Magic — It’s Math

The geometry of airflow creates or eliminates noise.

When you shape:

-

the duct angles

-

the vent layout

-

the return paths

-

the air handler location

-

the airflow velocity

-

the mounting isolation

…you shape the sound profile of your entire home.

Design for quiet, and your system becomes sustainably efficient — because quiet airflow is almost always low-static, low-energy airflow.

Quiet is green.

Quiet is engineered.

Quiet is Savvy. 🌿

Buy this on Amazon at: https://amzn.to/47usZUk

In the next topic we will know more about: Air Handler Optimization — Making the AMST60DU1300 Perform Like a High-End Eco System