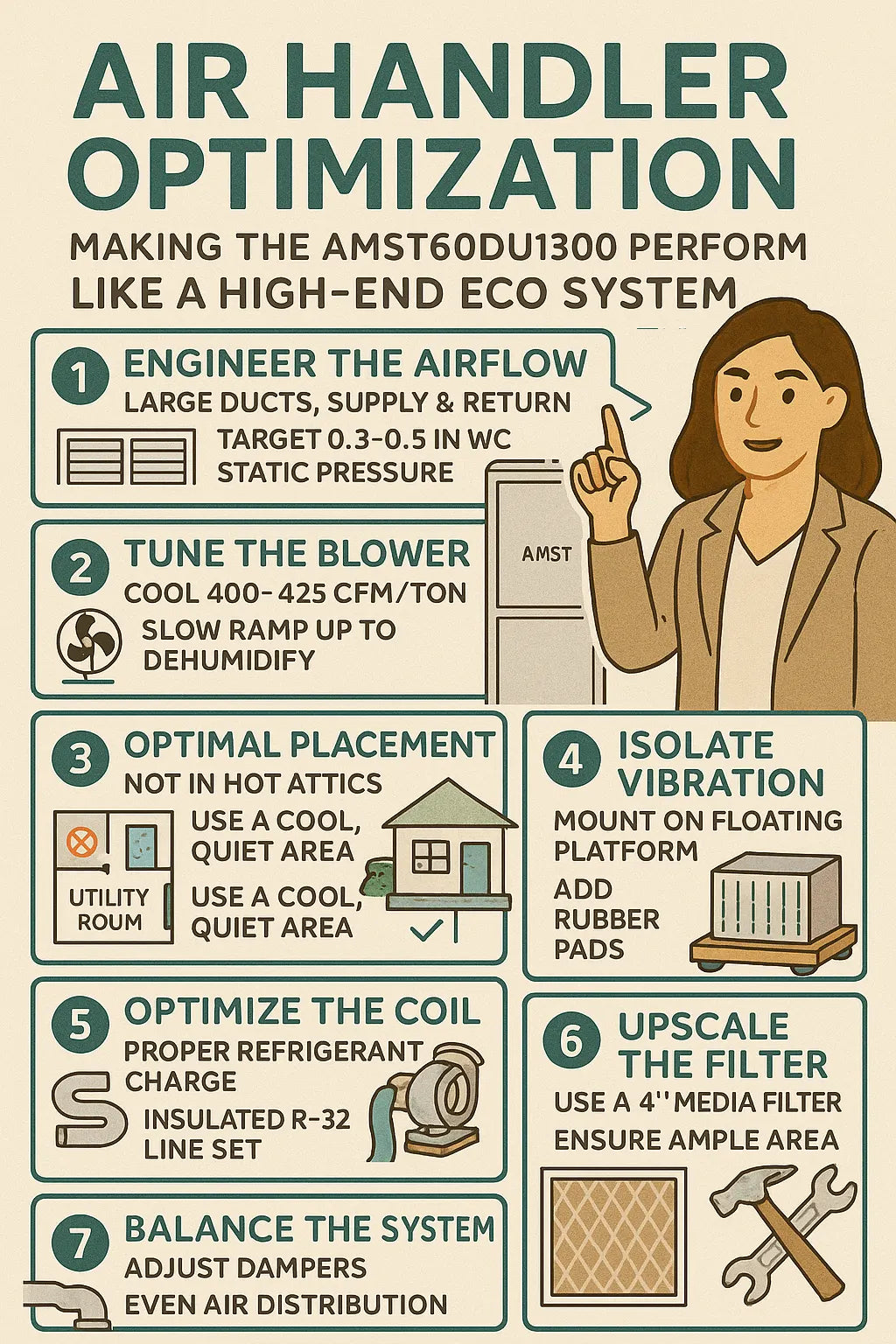

Introduction: The Secret to High-End HVAC Isn’t the Brand — It’s the Air Handler

You can buy the most efficient condenser on the market…

install the latest R-32 eco-friendly unit…

add a smart thermostat with all the bells and whistles…

But if your air handler isn’t optimized, your system will never perform like the high-end, eco-efficient powerhouse it’s supposed to be.

That’s why the Goodman AMST60DU1300 deserves this entire deep dive.

This air handler has the bones of a luxury system:

-

a high-efficiency ECM blower

-

variable-speed modulation potential

-

robust coil design

-

compatibility with R-32 refrigerant

-

multi-position versatility

-

low static tolerance for quieter, smoother airflow

But its performance depends almost entirely on how it’s installed, configured, balanced, and maintained.

Today, Savvy is here to show you how to turn the AMST60DU1300 into a high-end eco system that delivers whisper-quiet operation, lower energy bills, perfect airflow distribution, and the long-term sustainability modern HVAC homes deserve.

Let’s optimize this beauty from the inside out. 🌿

🧠 1. What Makes the AMST60DU1300 Special — The High-End Potential Hidden Inside

Before optimizing, you need to understand why this model can perform like premium equipment.

⚙️ 1.1 ECM Blower = High-End Efficiency at Heart

The AMST60DU1300 comes with an ECM motor, which:

-

self-adjusts torque

-

compensates for moderate static pressure

-

delivers smooth, quiet modulation

-

uses significantly less energy

-

improves comfort stability

DOE study on ECM energy savings:

🔗 https://www.energy.gov/energysaver/energy-saver

This is the same motor class used in high-end multi-stage and inverter systems.

❄️ 1.2 R-32 Coil Compatibility = Superior Heat Transfer

With R-32 refrigerant’s higher efficiency and lower Global Warming Potential (GWP), the air handler naturally supports:

-

faster heat absorption

-

better humidity control

-

higher cooling output

-

smoother coil temp stability

EPA R-32 Refrigerant Overview:

🔗 https://www.epa.gov/snap

🗃️ 1.3 Multi-Position Flexibility

Upflow

Downflow

Horizontal

This flexibility allows more climate-specific installation choices — a major optimization advantage.

🔧 1.4 5-Ton Capacity With Variable Airflow Tuning

This air handler can:

-

ramp slowly for humidity control

-

ramp fast for large spaces

-

maintain constant CFM for balanced comfort

But only if configured correctly.

🌬️ 2. The Airflow Formula — Making the Blower Work With Your Home, Not Against It

If you want your AMST60DU1300 to behave like premium equipment, you must engineer the airflow.

📏 2.1 Target Static Pressure: 0.3–0.5 in WC

The ECM motor can handle up to 0.8, but performance and efficiency drop dramatically above 0.5.

High static pressure causes:

-

noise

-

hot spots

-

coil freeze

-

poor dehumidification

-

energy spikes

Source: ACCA airflow standards

🔗 https://www.acca.org/standards/technical-manuals

📐 2.2 Duct Sizing Requirements for Optimal Performance

For a 5-ton air handler:

✔️ Main trunk: 16–18 inches

✔️ Branch ducts: 7–8 inches for large rooms

✔️ Returns: 2 large or 1 oversized return

✔️ Filter area: minimum 3–4 sq ft

Oversized ducts = quieter operation + smoother modulation.

🌀 2.3 Supply & Return Geometry Matters

Supply vents

-

should oppose heat gain

-

should not be placed behind doors

-

must be evenly distributed

-

must be sized to room CFM needs

Return vents

-

should be high-wall placement

-

should be centrally located

-

must match system tonnage airflow

EPA return-air recommendations:

🔗 https://www.epa.gov/indoor-air-quality-iaq

🔄 3. Blower Configuration — Where 80% of Performance Is Decided

This is the optimization most installers skip.

🚀 3.1 Cooling Mode: Medium-High Airflow

Ideal: 400–425 CFM per ton

Total: 1,600–1,700 CFM for a 4-ton condenser

or

2,000 CFM for a full 5-ton setup.

Why?

-

Improves coil efficiency

-

Reduces cycling

-

Spreads air evenly

-

Lowers energy use

🌫️ 3.2 Humidity Mode: Slow Ramp-Up

A 30–90 second slow start dramatically improves:

-

latent heat removal

-

humidity control

-

coil moisture retention

-

indoor comfort

Perfect for hot-humid climates.

🌬️ 3.3 Heating Mode: Medium or Medium-Low

Why?

-

prevents overshooting

-

maintains quieter operation

-

reduces blower stratification

🤫 3.4 Quiet Mode: Reduce Max Fan Speed by 10–20%

If your goal is noise reduction:

-

drop the fan speed

-

widen supply vents

-

open nearby dampers

This reduces pressure spikes and turbulence — making your AMST60DU1300 sound premium.

📍 4. Air Handler Placement — One of the Most Important Parts of Optimization

The AMST60DU1300 can be installed anywhere…

But not everywhere is good for performance.

🚫 4.1 Worst Placements

❌ Hot attics

Air handler temperature can exceed 130°F → massive efficiency loss.

❌ Garages in humid climates

Moisture kills blower bearings and electronics.

❌ Tight closets

Restricted airflow leads to noise + vibration.

❌ Directly under bedrooms

Transfer noise becomes impossible to eliminate.

🏡 4.2 Best Placements

✔️ Encapsulated attic

✔️ Interior utility room

✔️ Conditioned basement

✔️ Dedicated mechanical room

Goal: give your air handler a cool, quiet, stable environment.

ASHRAE mechanical room standards:

🔗 https://www.ashrae.org/technical-resources

🧰 5. Vibration & Noise Isolation — Making It Sound High-End

The AMST60DU1300’s ECM blower is naturally quiet, but optimization elevates it further.

🪵 5.1 Mount on a Floating Platform

Prevents resonance transfer through framing.

🧵 5.2 Add Rubber Isolation Pads Under the Unit

Reduces vibration by 40–60%.

📏 5.3 Don’t Let Ducts Touch Wall Studs or Joists

Use:

-

rubber-backed clamps

-

padded supports

-

flexible connectors

Duct vibration is louder than blower vibration.

🎛️ 5.4 Line the Return Plenum With Acoustic Duct Liner

This absorbs:

-

high-frequency fan noise

-

turbulence noise

-

transition resonance

🧼 6. Coil Optimization — The Hidden Power of Air Handler Efficiency

The AMST60DU1300 coil becomes a high-end coil when installed correctly.

❄️ 6.1 Proper Refrigerant Charge = Peak Efficiency

Undercharging reduces cooling capacity.

Overcharging causes noisy operation + high head pressures.

📐 6.2 Correct Line Set Sizing

R-32 systems need:

-

fully insulated suction lines

-

minimal bends

-

proper separation from walls

-

correct diameter based on distance

Improper line sets cause noise and vibration.

💦 6.3 Perfect Drainage = Longer Coil Life

Add:

-

float switch

-

correctly sloped pan

-

secondary drain

-

anti-microbial tabs

This prevents leaks and mold.

🌬️ 7. Filter Pathway Optimization — The Air Handler’s Lifeline

A restrictive filter reduces blower performance more than anything else.

📏 7.1 Use a 4" Media Filter (Not 1")

4" filters:

-

lower static

-

maintain airflow

-

protect ECM motors

-

operate quieter

-

improve IAQ

DOE filtration research:

🔗 https://www.energy.gov/energysaver/energy-saver

🛠️ 7.2 Ensure Enough Filter Area

At least:

3 sq ft (48 sq in) per ton

= 12–15 sq ft minimum for this air handler.

🧭 7.3 Central Return Is Best

Pulls air smoothly across the coil.

🧩 8. Duct Balancing — The Final Step That Makes Performance Feel “Premium”

✔️ Add manual dampers

✔️ Increase airflow to long duct runs

✔️ Reduce airflow to short runs

✔️ Measure room CFM

✔️ Balance static across trunk lines

A balanced system equals:

-

quieter operation

-

even room temps

-

lower bills

-

longer equipment life

🌎 9. Maintenance Blueprint — Keeping It Performing Like New

✔️ Clean coil every 12–18 months

✔️ Replace 4" filter every 4–6 months

✔️ Inspect blower wheel annually

✔️ Check condensate slope at every service

✔️ Test static pressure each season

Healthy air handler = efficient air handler.

🌿 Conclusion: The AMST60DU1300 Can Perform Like a Luxury System — If You Optimize It

With the right:

-

airflow

-

static pressure

-

blower tuning

-

placement

-

vibration control

-

filtration

-

duct geometry

…the AMST60DU1300 transforms into a high-end, eco-efficient, whisper-quiet system that rivals premium brands costing thousands more.

The equipment already has the capability.

You just need to unlock it.

And that — as always — is the Savvy way. 🌱

Buy this on Amazon at: https://amzn.to/47usZUk

In the next topic we will know more about: The Efficiency Envelope — How Your Home’s Construction Dictates System Design Success