By Tony — because a perfectly installed AC can still fail if the water has nowhere to go.

💧 1. Introduction — The Most Overlooked Problem in HVAC Installation

Ask any homeowner what causes AC failure.

They’ll say:

-

refrigerant

-

the blower

-

the thermostat

-

the condenser fan

Ask a rookie installer?

Same answers.

But ask Tony?

“Drainage. Drainage kills more systems than refrigerant ever will.”

Every summer, I respond to the same complaints:

-

“My AC is leaking.”

-

“The drip pan is overflowing.”

-

“Water is coming through the ceiling.”

-

“The unit won’t shut off.”

-

“The coil froze up.”

-

“There’s mold in my closet.”

In almost every case, the real cause is not the AC.

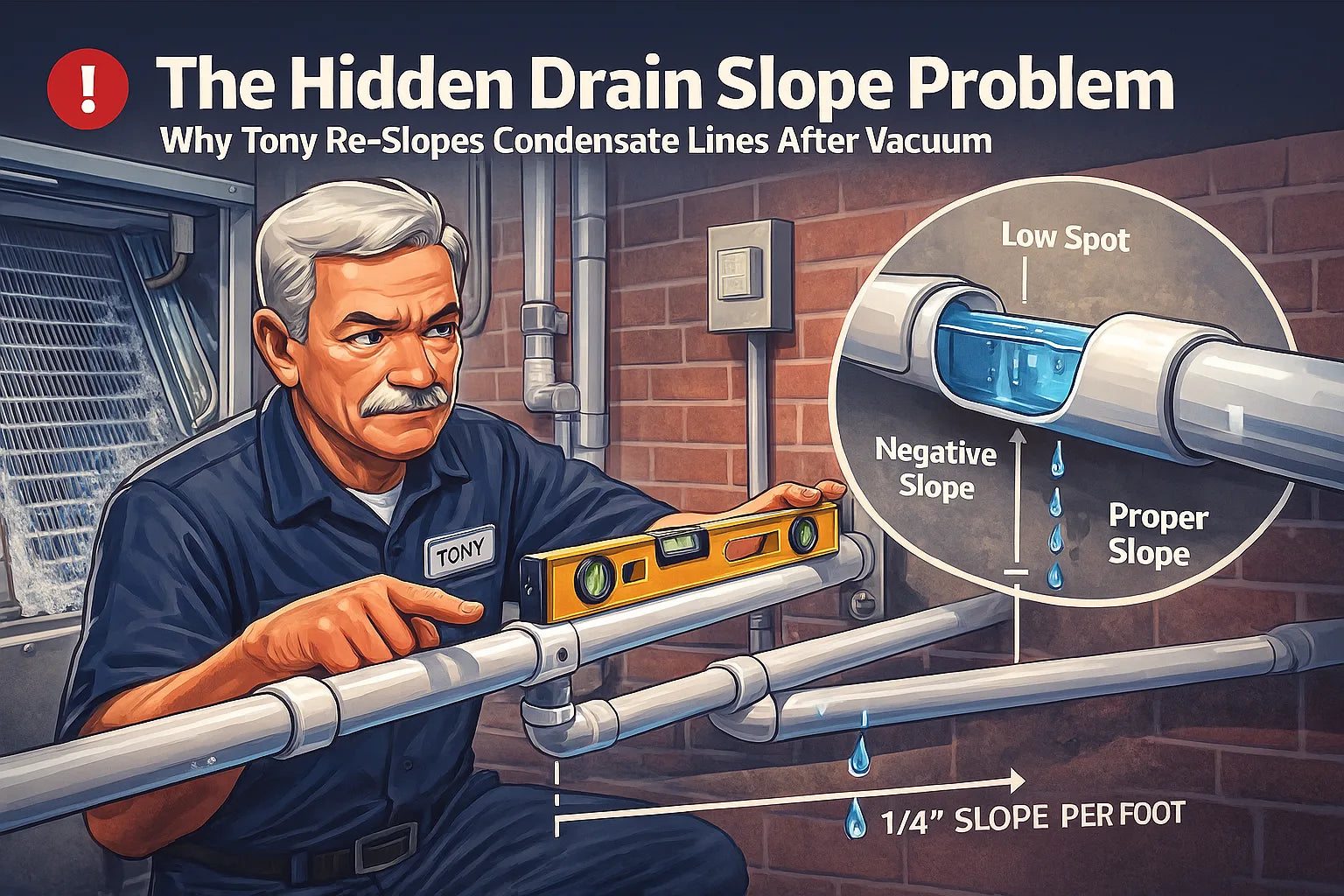

It’s the hidden drain slope problem — and the only reason it’s “hidden” is because installers forget something crucial:

Pulling vacuum causes the line set, coil cabinet, and drain assembly to shift — sometimes by as much as ¼ inch — which destroys the carefully set condensate slope.

That’s why Tony checks the drain slope after the vacuum is pulled, not before taping up the line or sealing the coil.

And once you understand what vacuum does to copper, PVC, and cabinets, you’ll never trust a pre-vacuum slope again.

🧰 2. The Science: Why Vacuum Changes the Geometry of Your Install

R-32, R-410A, or any refrigerant — the vacuum process is the same:

You’re pulling the entire system down to:

-

500 microns

-

often 300 microns for best practice

This does more than remove air and moisture.

✔️ It compresses the line set slightly

Long, unsupported runs of copper shift under negative pressure.

✔️ It pulls the coil cabinet downward by a tiny amount

Especially if the coil isn’t fully secured yet.

✔️ It flexes the drain pan

Plastic changes shape under pressure differentials.

✔️ It slightly pulls the furnace or air handler toward the line set entry point

Especially in closet or upflow applications.

✔️ It changes the weight distribution of the entire assembly

Because refrigerant liquid and vapor are no longer inside the tubing.

Remember:

When the system is in vacuum, physics is not on your side.

Copper expands and contracts.

PVC settles.

Wall penetrations shift.

Supports take weight differently.

A perfect slope BEFORE vacuum may be a bad slope AFTER vacuum.

And THAT is the hidden drain slope problem.

📏 3. How Much Slope Is Required? (And Why Most Installs Miss It)

Industry standard slope for condensate lines is:

¼ inch per foot

(or 2% gradient)

This ensures:

-

water flows by gravity

-

debris does not accumulate

-

no standing water sits inside the pipe

But here’s what installers forget:

A small shift from vacuum — just ⅛″ — can turn that:

-

¼" per foot slope

into -

0"

or -

negative slope (deadly)

Negative slope is the kiss of death:

-

water backs up

-

algae grows

-

drain pans overflow

-

secondary drains activate

-

ceilings leak

-

homeowners panic

-

techs blame TXVs, condensate pumps, and insulation

When the truth is:

The slope was perfect — until the vacuum changed everything.

🧊 4. The Six Ways Vacuum Ruins a Previously Perfect Condensate Slope

Tony has seen drain lines fail for decades.

Here are the most common vacuum-induced slope problems:

❌ 1. Copper Line Set Pull-In

Negative pressure pulls long horizontal line sets inward toward the coil.

This shifts:

-

the coil

-

the drain pan

-

the PVC trap

-

the first 3 feet of condensate line

A ⅛” shift = failure.

❌ 2. Cabinet Flexing

Modern metal cabinets are thinner than older units.

Under vacuum:

-

the front panel flexes

-

the base shifts

-

the drain outlet drops slightly

Your perfect slope becomes a bad angle instantly.

❌ 3. PVC Expansion & Contraction

PVC moves — both from pressure and temperature.

Vacuum + temperature change = expansion shift.

PVC looks rigid but is not.

❌ 4. Trap Misalignment

The P-trap is the heart of the drain system.

Vacuum often pulls:

-

the trap sideways

-

the outlet upward

-

the inlet downward

Suddenly your trap is no longer trapping — or worse, is trapping TOO much.

❌ 5. Furnace or Air Handler Lean

In tight closets, pulling vacuum pulls the coil toward the line penetration, causing:

-

uneven leaning

-

furnace tilt

-

plenum stress

-

drain outlet positional changes

❌ 6. Unseen Sagging in Horizontal Runs

Vacuum reduces internal support in long PVC runs.

Even a tiny sag:

-

traps water

-

creates a biofilm zone

-

breeds slime

-

reduces flow

-

leads to eventual overflow

🔍 5. Tony’s Drain Slope Reality Test — AFTER Vacuum

Here’s how I test slope once the vacuum is complete, not before:

🧭 Step 1 — Visual Re-Level of the Coil Cabinet

Check:

-

cabinet level

-

cabinet twist

-

coil pitch

-

pan alignment

Even ⅛" off = slope problems everywhere.

🧭 Step 2 — Check Trap Inlet Height vs Outlet Height

The trap must have:

-

higher inlet

-

lower outlet

-

proper water column depth

Vacuum can flip the inlet/outlet relationship dynamically.

🧭 Step 3 — Run 1–2 cups of water into the drain

Tony always pours water into the primary drain before sealing the coil.

What he looks for:

-

smooth flow

-

no stalls

-

no backward surge

-

no gurgling

-

no slow drainage

-

no standing puddles

If ANY of that happens — the slope is wrong.

🧭 Step 4 — Inspect Every Elbow and Horizontal Run

The line must maintain continuous slope:

-

no bellies

-

no upward dips

-

no sideways lean

Vacuum often induces micro-bellies in:

-

ceiling cavities

-

crawlspaces

-

attics

🧭 Step 5 — Shake Test

Tony lightly shakes the drain line to reveal:

-

hidden sags

-

unsupported segments

-

stress points

-

weak glue joints

If the pipe clicks or flexes, slope correction is needed.

🧭 Step 6 — Full System Test

Once refrigerant charge is confirmed:

≈ 10 minutes into cooling mode, water starts flowing.

Tony watches the drain:

-

smooth stream? good

-

pulsing or bubbling? slope issue

-

slow trickle? slope issue

-

noisy drain? slope issue

-

no flow? major problem

🔥 6. Real-World Examples of Vacuum-Induced Drain Failures

These are actual field cases Tony has fixed:

💀 Case 1 — “The attic waterfall”

The coil shifted ¼″ during vacuum.

The slope inverted.

Result:

-

14-foot PVC line filled with condensate

-

attic drywall caved in

-

$14,000 repair bill

💀 Case 2 — “The mystery backup”

Water flowed fine during initial test.

After vacuum, the sag deepened.

Result:

-

trap airlocked

-

coil pan filled

-

water poured into furnace

-

furnace shorted out

💀 Case 3 — “The foamy drain”

Vacuum pulled the trap sideways.

Result:

-

negative slope

-

algae grew in 10 days

-

customer smelled mildew

💀 Case 4 — “The line that hummed”

Vacuum pulled the line closer to a supply trunk.

Result:

-

water vibration

-

resonant humming

-

customer thought something was “living” in the wall

🧱 7. Tony’s Fix: Re-Sloping Every Drain After Vacuum (Step-by-Step)

🔧 1. Re-level the furnace or air handler

Even tiny shifts cause slope errors.

🔧 2. Re-align and re-secure the P-trap

Critical. Must be perfect.

🔧 3. Re-support the PVC every 4–6 feet

More supports = fewer bellies.

🔧 4. Re-pitch all horizontal runs

Laser level or digital inclinometer.

🔧 5. Add ¼″ slope per foot minimum

1/8″ slope is NOT enough.

🔧 6. Re-test drainage under load (10–20 minutes)

Water flow must be continuous.

🔧 7. Only when perfect — seal the coil

Tony seals last because:

-

once sealed

-

you can’t adjust the slope

-

you can’t observe the drain pan

-

you can’t fix internal alignment

📘 8. Verified External Technical Resources

Here are reputable, verified external resources supporting coil installation, condensate management, and TXV behavior:

-

ASHRAE Fundamentals – Coil Construction & Airflow (Technical)

https://www.ashrae.org/technical-resources/ashrae-handbook -

HVAC Drainage Code Requirements (ICC)

https://codes.iccsafe.org/ -

EPA HVAC Moisture & Condensate Guidelines

https://www.epa.gov/mold -

AHRI Air Coil Performance Standards

https://www.ahrinet.org/standards -

RSES TXV Installation & Superheat Guidelines

https://www.rses.org -

Goodman (Daikin) Coil & TXV Transition Resources

https://www.daikincomfort.com/

🏁 9. Final Thoughts — The Drain Line Is the Achilles Heel of Every System

Installers obsess over:

-

charge

-

superheat

-

subcool

-

flare nuts

-

vacuum microns

-

plenum

-

return air

But the drain line — the simplest component — is often the most damaging when installed incorrectly.

The vacuum shifts everything.

The slope changes.

The drain pan lies.

And the only way to stop leaks is to re-check slope after vacuum.

This is why Tony re-slopes every condensate line after vacuum — not before.

It prevents:

-

callbacks

-

water damage

-

fungal issues

-

premature equipment failure

-

angry customers

-

insurance claims

And most importantly?

It keeps the system running clean, dry, and reliable.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: R-32 Isn’t R-410A — Why Tony Changes His Line-Set Game When Installing the New Goodman 4-Ton