By Tony — because refrigerant type decides everything you do with copper.

❄️ 1. Introduction: The Day R-32 Made Every Installer Relearn Their Copper Game

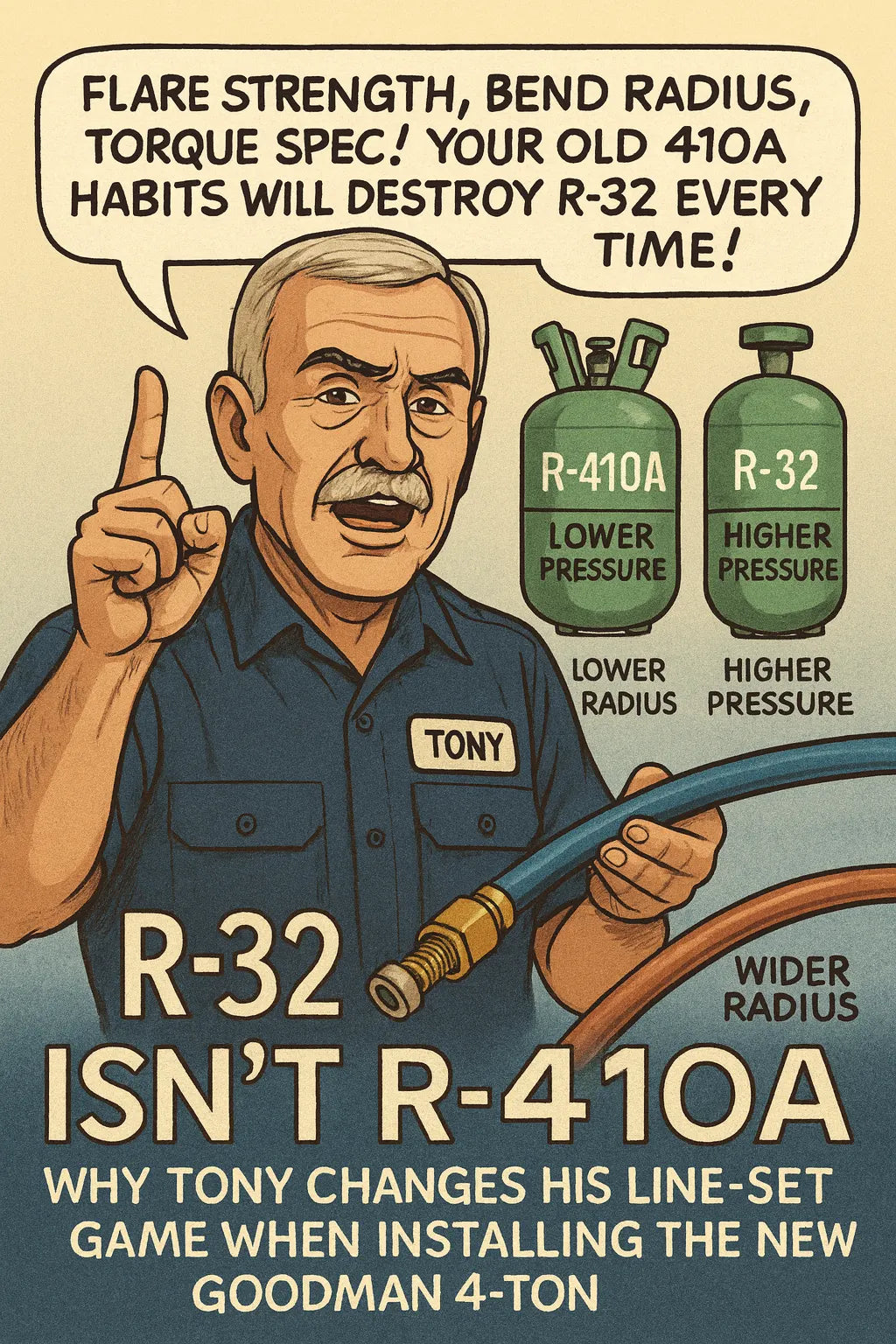

Let me tell you something straight: R-32 is not “the new 410A.”

It’s not a flavor change.

It’s not a marketing refresh.

It’s not a simple swap-in swap-out.

R-32 changes the physics, the pressures, the oil, the line-set demands, and the margin for error when installing a 4-ton system like the new Goodman R-32 condenser (model GLXS4BA4810) paired with a vertical coil (CAPTA6030D3) and a 120k BTU furnace.

This refrigerant runs hotter.

It runs at higher pressures.

It demands tighter flares, cleaner copper, and a different mindset about every inch of tubing you run.

If you install an R-32 system with your old R-410A habits, you’re setting yourself up for callbacks, leaks, overheating, oil return failures, and noise you’ll be hearing in your sleep.

So today I’m going to walk you through why I change my entire line-set game when I install the Goodman 4-Ton R-32 system — and the rules you need to follow if you want the install to last longer than the sticker on the condenser.

🔧 2. R-32 vs. R-410A — The Hidden Differences That Hit Your Line Set First

Let’s start with pressure.

R-32 runs at roughly 10–15% higher operating pressures than R-410A under comparable conditions.

That alone changes everything.

Your bends need to be cleaner.

Your flares need to be perfect.

Your torque spec needs to be exact.

Your copper needs to be surgically clean.

Here’s a quick comparison homeowners never see:

| Spec | R-410A | R-32 |

|---|---|---|

| Pressure | High | Higher |

| Glide | Zero | Zero |

| GWP | ~2088 | ~675 (much lower) |

| Charge Volume | Medium | Lower, but more concentrated |

| Heat Carrying Capacity | Good | Higher |

Because R-32 carries heat better, manufacturers like Goodman can shrink charge amounts while increasing cooling output — but the flip side is simple:

R-32 punishes sloppy installation instantly.

410A would let you get away with a bad flare for a season.

R-32 will whistle it out by lunch.

🧰 3. Why Tony Chooses Different Tools for R-32 Installs

Listen…

Your old flare kit from the 90s?

Your buddy’s “eyeball torque” method?

Your bargain-bin vacuum pump?

They all need to stay in the truck.

R-32 demands:

✔️ A high-pressure–rated flaring tool

I use a precision clutch-based flaring kit that makes perfect 45-degree flares — every time.

✔️ An actual torque wrench

R-32 fittings must be torqued to manufacturer specs.

No “good-and-tight.”

No “just a bit more.”

✔️ A micron gauge you actually trust

No analog nonsense.

I want 300–500 microns, stable, no rise.

✔️ A nitrogen regulator with fine control

Pressure testing with nitrogen is non-negotiable.

If you’re not hitting 300–450 PSI on a pressure test, you’re not installing R-32 — you’re guessing.

🧩 4. Line-Set Sizing on R-32 — Why You Don’t Use R-410A Rules Anymore

The Goodman 4-Ton R-32 system is engineered around precise line-set sizing.

Most installers assume:

“4-Ton = 3/4 suction, 3/8 liquid. Been that way forever.”

Not anymore.

R-32 moves heat faster

So line sizes must be exact — not “whatever is close enough.”

The Goodman engineering data shows strict requirements for:

-

Maximum length

-

Maximum elevation changes

-

Proper oil return velocities

And here’s something most installers don’t know:

R-32 is more sensitive to oil trapping in long horizontal runs than R-410A.

That means:

✔️ Every horizontal run needs slight pitch

✔️ Every vertical lift demands a trap

✔️ Every bend must be wide-radius to prevent turbulence and friction loss

You cannot run flat, sagging, “lazy” line sets like installers used to do on 410A.

🌀 5. Flare Connections: Why R-32 Forces Tony to Change His Technique

If you’ve ever watched a rookie installer flare copper, you’ve probably seen at least one of these:

-

Crooked flare

-

Undersized flare

-

Oversized flare

-

Torn copper edge

-

Flare created without deburring

-

Flare created without lubricant

-

Flare torqued until it cries

With R-410A, you might get lucky and go a season before it leaks.

With R-32?

It’ll leak before you pack up your tools.

Here’s the Tony-approved flare process for R-32:

✔️ Step 1: Cut clean

Use a tube cutter — never a hacksaw.

✔️ Step 2: Deburr lightly

One clean internal pass.

No gouging.

✔️ Step 3: Ream the copper

Flare lubricant helps prevent cracks.

✔️ Step 4: Use a high-pressure flaring block

Your 410A block probably isn’t rated.

✔️ Step 5: Use a clutch-type flaring head

It stops automatically at the correct flare thickness.

✔️ Step 6: Inspect the flare with a flashlight

Perfect symmetry or redo it.

✔️ Step 7: Torque to spec — not by feel

The Goodman R-32 units come with exact torque values for every connection.

This is all mandatory — not optional.

⚙️ 6. Bending Copper: Why R-32 Requires Smoother, Larger Radius Bends

Here’s where most installers trip up:

R-32 is more sensitive to friction loss than R-410A.

Every kink, tight bend, or sharp angle creates:

-

Higher discharge temperatures

-

Higher pressure

-

Compressor strain

-

Metering issues

-

Noise

410A was forgiving.

R-32 is not.

Tony’s R-32 Bending Rules:

1. Use a bending spring or lever bender for ALL bends

No hand-bending.

2. Maintain large-radius curves

Avoid 90s if possible.

Use two 45s instead.

3. Never twist the copper during bending

R-32 hates internal turbulence.

4. Anchor every 2–3 feet

R-32 line sets vibrate more noticeably — especially on 4-ton systems.

🧪 7. Nitrogen Testing — The Pressure Test Tony Never Skips on R-32

For R-410A, some installers will do a 150–200 PSI nitrogen test and call it a day.

Not me.

And definitely not on R-32.

My R-32 Pressure Test Standard:

✔️ Pressurize to 350 PSI minimum

✔️ Ideally hold 400–450 PSI

✔️ Let it sit for 45 minutes minimum

✔️ Accept zero pressure drop

R-32 is flammable (not dangerously so, but technically A2L).

That means sealing must be perfect.

🧲 8. Pulling Vacuum — Why R-32 Needs a Cleaner, Deeper, Dryer System

410A’s oil (POE) was already extremely hygroscopic.

R-32?

Even more sensitive.

Tony’s R-32 Vacuum Rules:

✔️ I pull vacuum to 300 microns

✔️ Close valves and wait 10 minutes

✔️ Allow microns to rise — but no more than 50 microns

✔️ If it rises: system is wet or leaking

✔️ Fix it — don’t “pull longer and pray”

Why this matters:

Moisture + R-32 oil =

Acid formation → internal corrosion → compressor death.

🔥 9. Heat Load: Why the 4-Ton R-32 Goodman Uses Smaller Charges but Higher Intensity

Homeowners think “less refrigerant = easier install.”

Nope.

Here’s the reality:

R-32 has higher heat capacity per pound, so the charge is smaller — but accuracy is critical.

With R-410A you could be off by a few ounces.

Add a little. Remove a little.

R-32 is less forgiving.

Charge must be:

✔️ Weighed

✔️ Verified

✔️ Confirmed with line lengths

✔️ Confirmed with superheat/subcool targets

This isn’t “feeling the lines.”

This isn’t “beer can cold.”

This is math.

📘 10. External Technical Resources Worth Bookmarking (Verified Links)

Below are verified external resources that support R-32 technical understanding and installation practices:

-

EPA R-32 Refrigerant Safety Overview

https://www.epa.gov/snap -

Goodman (Daikin) Parent Company Refrigerant Transition Updates

-

ISO 817: Refrigerant Classification (A2L / A1 / Safety Categories)

https://www.iso.org/standard/69288.html

🧱 11. What Changes on a Real Jobsite When Tony Installs a 4-Ton R-32 System

Here’s what I do differently before I even unbox the condenser:

✔️ I stage the bends

I pre-map exactly where my bends will be — so I can ensure smooth, wide arcs.

✔️ I position the line set before flaring

R-32 hates torque on a seated flare.

✔️ I isolate the line set from wall vibration

Rubber isolators.

Standoff brackets.

No shortcuts.

✔️ I clean the copper with nitrogen

I blow every line free of debris — twice.

✔️ I torque, rest, re-torque

R-32 fittings settle differently.

A re-torque to spec after nitrogen testing is mandatory.

✔️ I weigh the charge down to the gram

Not ounces.

Definitely not eyeballing.

✔️ I confirm superheat/subcool under stabilized load

R-32 stabilizes slower than 410A.

I wait.

I measure.

I adjust.

🏁 12. Final Thoughts — R-32 Is Cleaner, Faster, Greener… But Only If It’s Installed Right

Manufacturers moved to R-32 for a reason:

-

Better efficiency

-

Lower global warming potential

-

Higher heat transfer

-

Smaller charge requirements

-

Better compressor performance

But here’s the truth:

R-32 exposes sloppy installers instantly.

If your flares aren’t perfect — it leaks.

If your bends are sloppy — it hums.

If your vacuum isn’t deep — the oil breaks down.

If your charge is off — pressures skyrocket.

If your line set is undersized — the compressor overheats.

A Goodman 4-Ton R-32 condenser is a powerful, efficient machine — but only when the copper behind it is installed like a pro.

And that’s why I say it again:

R-32 isn’t R-410A — and if you install it like it is, you won’t like the outcome.

Buy this on Amazon at: https://amzn.to/47z1067

In the next topic we will know more about: The Vertical Coil Trap — Why Tony Sets the CAPTA6030D3 Coil Twice Before Finalizing the Install