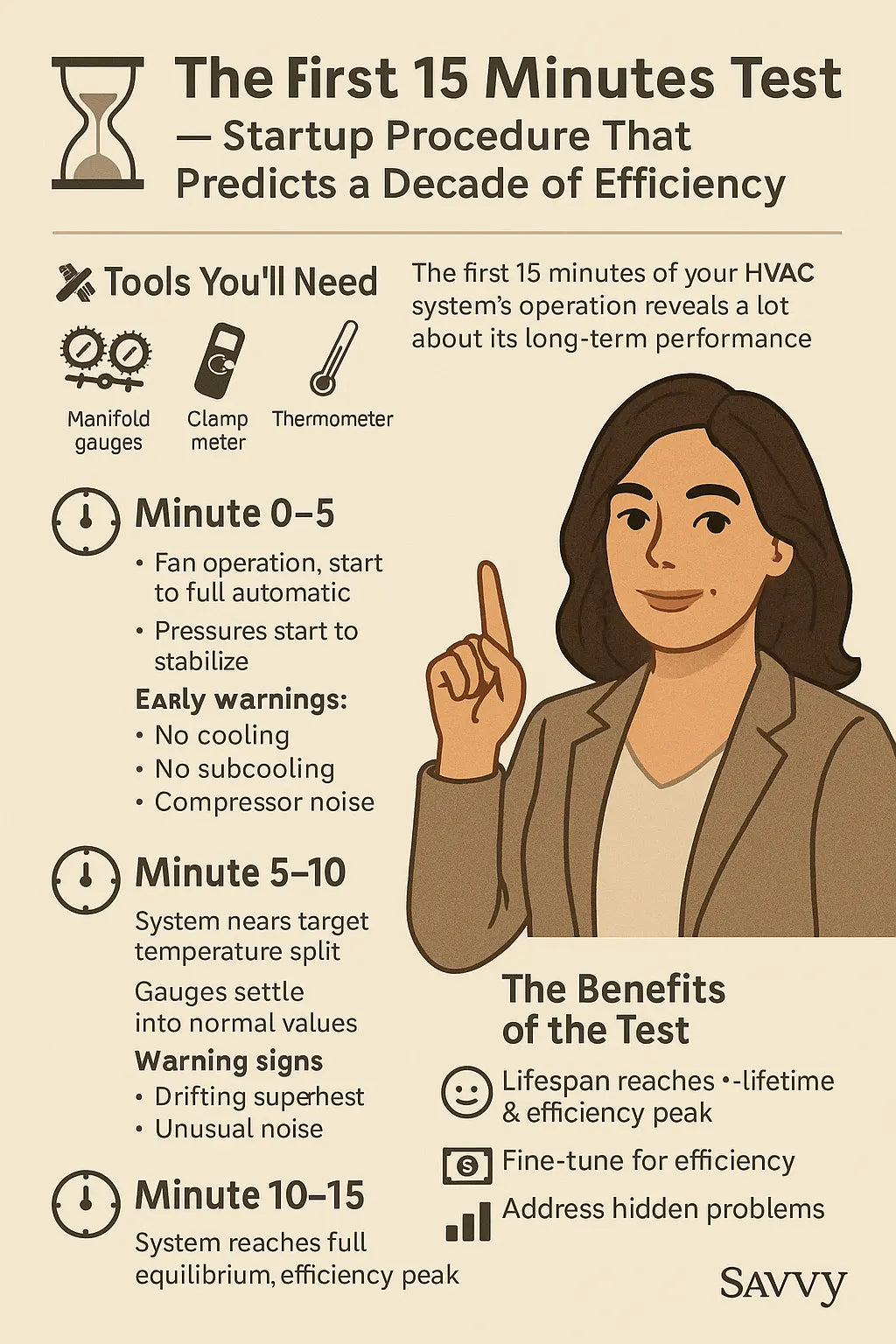

🌿 Introduction: The Most Important 15 Minutes of Your System’s Life

Most homeowners think HVAC efficiency is determined by equipment specs — SEER2 ratings, compressor type, blower speed, refrigerant, or duct layout. But Savvy knows there’s one moment that matters more than anything:

The first 15 minutes after startup.

This short window tells you:

-

Whether your refrigerant circuit is healthy

-

Whether airflow is adequate

-

Whether the TXV/EEV is behaving

-

Whether pressures are stable

-

Whether the coil is loading heat correctly

-

Whether the system is tuned for a decade of performance

-

Whether the homeowner will enjoy quiet, consistent comfort — or years of repairs

The “First 15 Minutes” Test is a predictive diagnostic.

Done correctly, it becomes a crystal ball for system longevity.

Let’s walk through it, Savvy-style.

🔌 1. Why the First 15 Minutes Matter More Than Most Homeowners Realize

Icon: ⏱️

Right after startup, the system transitions through several phases:

-

Initial compressor surge

-

Refrigerant pressure equalization

-

Coil saturation

-

Thermal stabilization

-

System equilibrium

If anything goes wrong during these phases, the system may still cool, but it will:

-

Run louder

-

Use more electricity

-

Wear the compressor faster

-

Lose 10–30% of efficiency

-

Suffer from premature failure

The First 15 Minutes Test reveals these hidden problems before they become expensive problems.

🧠 2. Tools You Need for the Test

Icon: 🧰

A seasoned tech or Savvy homeowner will have:

-

Digital manifold gauges

-

Temperature probes (supply/return/coil lines)

-

Clamp meter (amps)

-

Thermometer or hygrometer

-

Static pressure manometer

-

Anemometer (optional)

-

Smart thermostat with data tracking (highly recommended)

With these tools, you can observe the system’s entire startup behavior.

⚙️ 3. Minute-by-Minute Breakdown — What Should Happen and When

Icon: 📊

Here is the full Savvy diagnostic timeline:

🟩 Minute 0–1: Initial Startup Surge

What Should Happen:

-

Compressor kicks on without hesitation

-

Fan motor ramps smoothly

-

No loud clanking or vibration

-

No unusual humming or buzzing

What You’re Checking:

-

Locked rotor amperage (LRA) not triggered

-

Voltage stable

-

Start capacitor (if used) functioning

Red Flags:

-

Long crank time

-

Clicking

-

High vibration on pad

-

Fan sputtering

This predicts future compressor or capacitor failures.

🟩 Minute 1–3: Pressures Begin to Stabilize

What Should Happen:

-

Suction pressure starts descending

-

Liquid pressure starts rising

-

Subcooling begins to form

-

Superheat begins to settle

Target Values:

(General R-410A/R-32 system — always check manufacturer charts)

| Metric | Expected Range |

|---|---|

| Suction Pressure | 110–140 psi (R-410A) |

| Liquid Pressure | 350–425 psi |

| Subcooling | 8–14°F |

| Superheat | 8–20°F |

Red Flags:

-

Flatlined pressures

-

Wild fluctuations

-

Extremely high head pressure

-

No subcooling after 2–3 minutes

This stage predicts refrigeration-side issues like charge problems or TXV malfunction.

🟩 Minute 3–5: Coil Saturation Phase

What Should Happen:

-

Indoor coil achieves full thermal load

-

Return air temperature begins dropping

-

Supply air temperature stabilizes

-

Condenser fan exhaust becomes warmer

Target Values:

-

15–22°F temperature split typically ideal

-

Supply temp often 55–60°F under normal humidity

Red Flags:

-

Weak temperature split

-

No noticeable cooling

-

Coil freeze-up

-

Excess sweating on suction line

This phase predicts airflow issues or refrigerant mischarge.

🟩 Minute 5–10: System Approaches Steady-State Operation

What Should Happen:

-

Pressures steady, non-fluctuating

-

Subcool/superheat settle into target range

-

Fan noise levels consistent

-

Thermostat begins learning cycle behavior

Red Flags:

-

Rising amp draw

-

Excessive noise

-

Sweating compressor

-

Suction line below 32°F

-

Condenser fan blowing cold or lukewarm air

This stage predicts long-term compressor health.

🟩 Minute 10–15: Full Equilibrium Reached

What Should Happen:

-

System efficiency peaks

-

Temperature split remains constant

-

Refrigerant circuit fully saturated

-

Coil moisture removal becomes stable

-

Compressor amperage normalizes

Red Flags:

-

Temperature split drifting downward

-

Humidity not dropping

-

Amp draw creeping upward

-

Subcool drifting continuously

-

Low or unstable airflow

Minute 15 predicts the next 10 years of your system’s performance.

If the system behaves well here, it will behave well long-term.

🌬️ 4. Airflow Testing During the First 15 Minutes

Icon: 🌪️

Airflow is the hidden backbone of efficiency.

Tests to Perform:

1. Static Pressure Test

Target:

≤ 0.5" WC total external static

High static =

-

Noisy operation

-

Low efficiency

-

Coil freeze-up risk

2. CFM Measurement

General rule:

350–400 CFM per ton

A 3-ton Goodman system should deliver:

1,050–1,200 CFM

3. Filter Differential Pressure

Clogged filters reveal themselves fast in the startup window.

A smart thermostat may flag reduced airflow, but tools confirm it.

4. Duct Leakage Awareness

If temperatures drift too slowly, duct leakage is often the culprit.

💧 5. Humidity Response — The “Hidden Efficiency” Metric

Icon: 🌫️

Humidity removal is a major aspect of cooling efficiency.

What You Want to See in 15 Minutes:

-

RH drops by 1–4%

-

Coil condensation stabilizing

-

Suction line sweating normally

-

No re-evaporation from fan cycling

If humidity is unchanged:

-

Airflow is too high

-

Coil is too warm

-

Charge may be off

-

Indoor fan runtime mode needs adjustment

Humidity stability in the first 15 minutes predicts comfort quality for the entire season.

🔊 6. Acoustic Diagnostics — Noise Tells the Truth

Icon: 🔈

Most mechanical problems announce themselves early through sound.

During the 15-minute test, listen for:

✔️ Normal Sounds:

-

Smooth fan whoosh

-

Mild compressor hum

-

Even airflow through vents

❌ Abnormal Sounds:

-

Buzzing

-

Clicking

-

Rattling

-

Pulsing

-

Whistling at vents

-

Clanging metal

Noise signatures often predict failing capacitors, loose mounts, improper refrigerant velocity, or duct design flaws.

🔥 7. Electrical Behavior — Amps, Voltages & Startup Current

Icon: 🔌

The First 15 Minutes Test includes monitoring:

-

LRA (Locked Rotor Amps)

-

RLA (Rated Load Amps)

-

FLA (Full Load Amps)

-

Voltage drop under load

What You Want:

-

Startup spike → quick drop

-

Running amps stable

-

Voltage consistent

Red Flags:

-

Spiking amps

-

Continuous rise in amps

-

Voltage sag >5%

These predict motor and compressor longevity.

🧊 8. Temperature Split Analysis — The Heart of the Test

Icon: 🌡️

A stable 15–22°F delta T during the first 15 minutes shows:

-

Good airflow

-

Correct refrigerant charge

-

Proper coil performance

-

Tight ductwork

-

Balanced return/supply

-

Healthy compressor

-

Good humidity control

A dropping or unstable split?

That’s the system waving a flag.

🧪 9. TXV/EEV Behavior — The Brain of the Refrigerant Circuit

Icon: 🧬

The TXV or EEV meters refrigerant precisely.

What Healthy Metering Looks Like:

-

Superheat stabilizes within 10–20°F

-

Subcool stabilizes within 8–14°F

-

Pressure fluctuations reduce over time

Red Flags:

-

Superheat swings

-

Chattering valve

-

No subcool

-

High head pressure

-

Low suction pressure

Metering problems often appear between minutes 5–12.

🧊 10. Condenser Exhaust Temperature — The Breath of the System

Icon: 💨

Use a thermometer at the condenser discharge.

Healthy exhaust:

110–150°F depending on ambient temperature.

Overheated exhaust:

Indicates recirculation issues — often due to poor clearance or sunlight exposure.

📉 11. Early Failure Prediction — What the First 15 Minutes Can Reveal

Icon: 🔍

This test can catch:

-

Low refrigerant charge

-

Overcharge

-

TXV issues

-

Coil clogging

-

Blower problems

-

Weak capacitors

-

Bad fan motors

-

Duct imbalance

-

High static pressure

-

Failing compressor

-

Incorrect airflow settings

-

Poor installation practices

-

System oversized or undersized

Think of it like an EKG for your HVAC system.

🏆 12. When the First 15 Minutes Look Perfect — What It Means for the Next 10 Years

Icon: ⭐

A system that passes all thresholds in the first 15 minutes will:

-

Run quieter

-

Use less energy

-

Reduce carbon emissions

-

Maintain coil health

-

Avoid compressor overheating

-

Maintain stable temperatures

-

Control humidity consistently

-

Require fewer repairs

-

Last much longer

This is the long-term benefit of proper startup.

🔧 13. How to Document the First 15 Minutes — Savvy’s Template

Icon: 📋

Record:

-

Ambient temperature

-

Return/supply temps

-

Suction/liquid pressures

-

Superheat/subcool

-

Delta T

-

Humidity

-

Amps

-

Static pressure

-

Exhaust temperature

-

Fan speed

-

Noise notes

This turns the test into a professional-grade diagnostic.

🌎 14. Sustainability Wins — Why the First 15 Minutes Are a Climate Tool

Icon: 🌱

A properly tuned startup:

-

Reduces watt draw

-

Prevents refrigerant leaks

-

Prevents over-exhaust conditions

-

Increases SEER2 performance

-

Protects compressors from early failure

-

Reduces landfill waste

-

Lowers carbon footprint

Sustainability starts with precision — and the First 15 Minutes Test is pure precision.

🔗 Final Verified Resources

-

EnergyStar HVAC Installation Guidelines

https://www.energystar.gov -

ACCA System Startup Procedures

https://www.acca.org -

ASHRAE Refrigerant & Compressor Behavior Standards

https://www.ashrae.org -

Building Science Corporation — Mechanical System Diagnostics

https://buildingscience.com -

EPA Indoor Air Quality & Moisture Standards

https://www.epa.gov/indoor-air-quality-iaq

🌟 Closing: A 15-Minute Ritual That Protects a Decade of Comfort

The First 15 Minutes Test isn’t just a diagnostic routine.

It’s the moment your HVAC system reveals who it will be for the next decade.

Will it be loud or quiet?

Efficient or wasteful?

Reliable or repair-prone?

Climate-smart or carbon-heavy?

Comfortable or inconsistent?

The answers appear in that tiny, powerful 15-minute window.

Interpret it correctly, and you unlock a lifetime of Savvy-approved performance.

Buy this on Amazon at: https://amzn.to/4hyDyKH

In the next topic we will know more about: Dual-Fuel Harmony — Installing AC + Gas Furnace Systems That Think (and Breathe) Like One Machine