Installing a propane or garage heater seems simple: mount the unit, run the gas line, wire the circuit, and flip the switch.

But ask any electrician and they’ll tell you:

The wiring isn’t the hard part — the planning is.

Electrical panels have rules.

Heaters have rules.

Your home’s load capacity has rules.

And if you don’t respect them, you get:

-

tripped breakers

-

overheated wires

-

panel overload

-

equipment failure

-

safety hazards

-

wasted energy

-

major repair bills

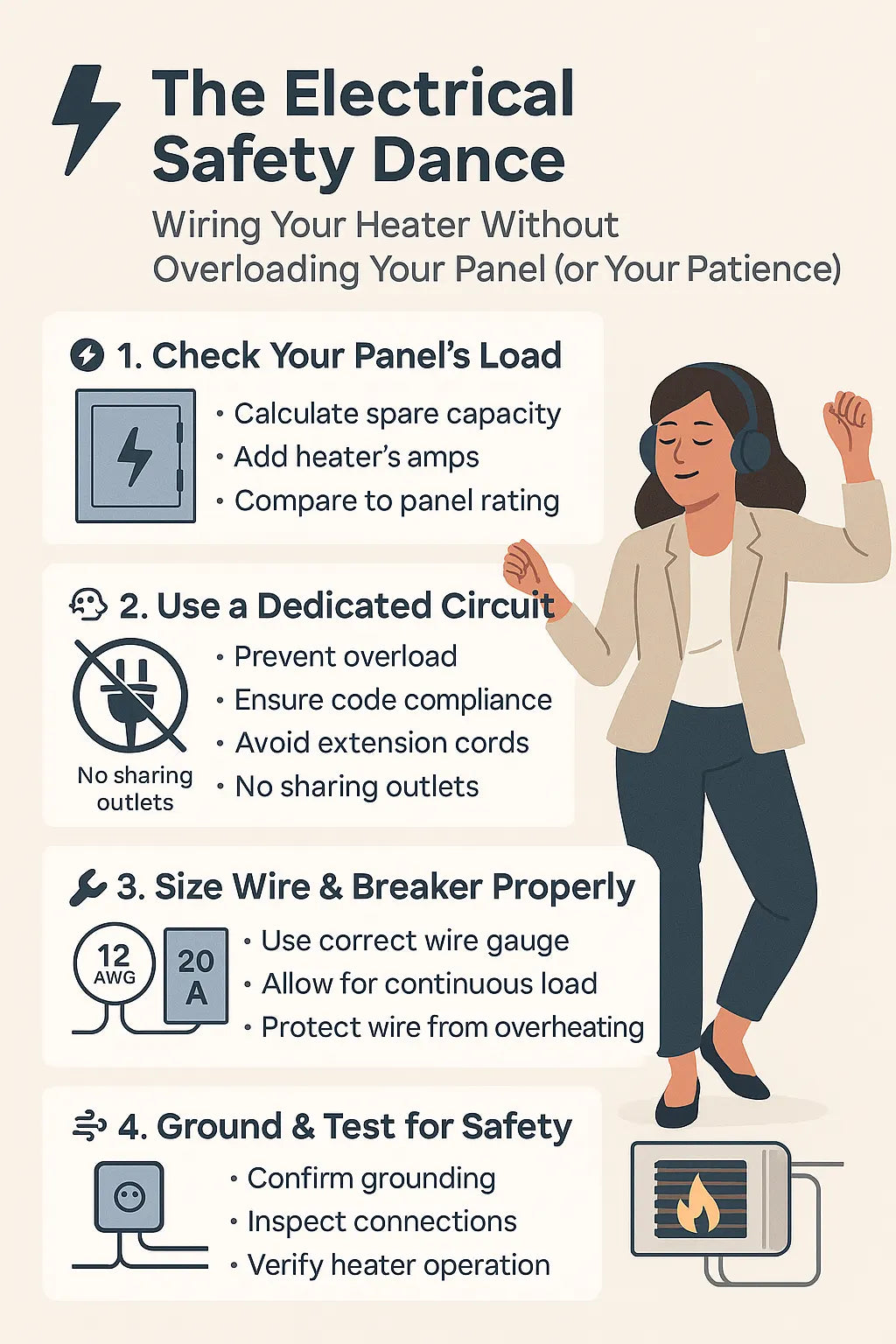

This guide walks you through the Electrical Safety Dance — Savvy’s methodical, eco-conscious, stress-reducing approach to wiring any shop heater, garage heater, or vented propane appliance without overloading your system or your sanity.

Let’s dance.

Reznor UDX 60,000 BTU Propane Unit Heater

⚡ 1. Why Electrical Planning Matters More Than You Think

Even gas or propane heaters require electricity for:

-

blower motors

-

igniters

-

safety circuits

-

thermostats

-

exhaust fans (in some models)

-

condensate pumps (if applicable)

Many homeowners underestimate electrical needs, which leads to dangerous improvisation.

⚠️ 1.1 What Goes Wrong When Electrical Loads Aren’t Planned?

-

overheated wires

-

nuisance tripping

-

melted insulation

-

damaged heater motors

-

code violations

-

reduced heater lifespan

-

shock hazards

Electrical failures are among the top contributors to residential fires, according to the U.S. Fire Administration:

https://www.usfa.fema.gov

Savvy rule:

If the panel isn’t right, the heater can’t be right.

📊 2. Load Calculation — The Heart of the Electrical Safety Dance

Before touching a wire, determine if the panel can support the heater.

This is what electricians call a load calculation — a required step in the National Electrical Code (NEC).

NEC reference:

https://www.nfpa.org

📊 2.1 Step 1 — Find Your Heater’s Electrical Requirements

Most propane or natural gas unit heaters require:

-

120V or 240V

-

3–12 amps

-

a dedicated circuit

Look at the heater’s nameplate or installation manual.

📊 2.2 Step 2 — Assess Your Current Panel Load

Locate your main panel and examine:

-

breaker sizes

-

labels (if any)

-

available spaces

-

total amperage rating (commonly 100A, 125A, 150A, 200A)

Now total up your running loads:

Examples of typical loads:

-

electric dryer: 20–30A

-

oven/range: 30–50A

-

HVAC blower: 3–7A

-

garage tools: 10–20A

-

lighting circuits: 5–10A

For accuracy, homeowners can use the DOE home electrical guidance

📊 2.3 Step 3 — Determine Spare Capacity

Use this formula:

Spare Capacity = Main Breaker Rating – (Total Running Load × 1.25)

The ×1.25 accounts for NEC continuous load requirements.

If the number is less than the heater's amps, the panel cannot support the unit without upgrades.

🧠 3. Understanding Dedicated Circuits — Your Heater Wants Its Own Dance Floor

Most heaters require a dedicated circuit, meaning:

-

nothing else shares the breaker

-

no outlets

-

no lights

-

no tools

-

no extension cords

Why Dedicated Circuits Matter:

-

prevents overload

-

reduces electrical noise

-

ensures clean power to motor and igniter

-

ensures code compliance

-

reduces fire risk

Electric heaters, mini splits, and propane heaters with high draw components all depend on isolation.

🔌 4. Choosing the Right Voltage — 120V vs. 240V

Some heaters allow dual-voltage operation.

🌡️ 120V Advantages

-

simpler wiring

-

lighter breakers

-

more circuits available

🌡️ 240V Advantages

-

more efficient motor performance

-

less voltage drop

-

quieter operation

-

handles longer runs

-

reduces amp load

Savvy rule:

If your heater supports 240V, wire it at 240V for quieter, more efficient operation.

🔧 5. Wiring Gauge, Conduit & Routing — The Physical Side of the Dance

🔧 5.1 Wire Gauge Matters

Use the correct gauge wire:

| Amps | Minimum Wire Gauge |

|---|---|

| 15A | 14 AWG (copper) |

| 20A | 12 AWG (copper) |

| 30A | 10 AWG (copper) |

| 40A+ | 8 AWG or larger |

Copper or aluminum?

Savvy says: Copper. Always copper.

Aluminum wiring introduces unnecessary risk.

🔧 5.2 Conduit Requirements

Garages and workshops often require:

-

EMT metal conduit

-

PVC Schedule 40 or 80

-

Flexible metallic conduit

Why?

Because exposed wiring must be protected from:

-

physical damage

-

moisture

-

pests

-

heat

Conduit installation ensures long-term safety and serviceability.

🔧 5.3 Routing Strategy

Routes should be:

-

direct

-

free from sharp bends

-

away from gas piping

-

away from heat sources

-

accessible

Savvy’s shortcut:

Trace your path on the wall before cutting a single piece of conduit.

🧯 6. Breaker Sizing — The Rhythm of Electrical Safety

A breaker’s job is not to protect the heater.

Its job is to protect the wire.

If the heater needs 12A but you install a 30A breaker on 14-gauge wire, the wire melts before the breaker trips.

This is the #1 cause of electrical fire.

🧯 6.1 How to Choose the Right Breaker

Step 1: Check heater’s amp requirement

Step 2: Multiply heater amps × 1.25

(to meet continuous-load rules)

Step 3: Select the next breaker size up

Example:

10A heater → 10 × 1.25 = 12.5A → use a 15A breaker.

🧯 6.2 AFCI & GFCI Requirements

Garages often require:

-

GFCI protection for safety

-

AFCI protection for fire prevention

Your heater may need:

-

a GFCI breaker

-

a GFCI outlet

-

or both, depending on code updates

NEC updates often refine these rules; always check 2020/2023 code versions.

🌬️ 7. The Grounding & Bonding Two-Step (Don’t Skip It)

Grounding protects you from shock.

Bonding protects your system from surges.

Mistakes here can lead to:

-

nuisance trips

-

heater shutdown

-

motor failure

-

fire risks

🌬️ 7.1 Grounding Requirements

Ground wires must:

-

match or exceed circuit gauge

-

be connected to the panel’s grounding bus

-

bond securely to the heater chassis

🌬️ 7.2 Bonding to CSST Gas Line

If you use CSST gas piping, it must be bonded to prevent lightning damage.

This is not optional.

🔍 8. The Savvy Wiring Sequence — A Step-by-Step Installation Flow

This is how professionals wire safely and efficiently:

Step 1 — Turn Off Main Power

Never trust a breaker label; test with a voltage tester.

Step 2 — Install the Breaker FIRST

This confirms panel acceptance and ensures wiring has a destination.

Step 3 — Route Conduit & Pull Wire

Work slowly to avoid insulation damage.

Step 4 — Make Terminations at the Heater

Connect:

-

ground

-

neutral (if required)

-

hot(s)

Follow the wiring diagram exactly.

Step 5 — Make Terminations at the Panel

Ensure wire gauge matches breaker requirements.

Step 6 — Install Disconnect Switch (If Required)

Many heaters require a service disconnect within sight.

Step 7 — Turn Power On & Test Voltage

Verify:

-

correct voltage

-

polarity

-

grounding integrity

Step 8 — Test Heater Operation

Look for:

-

smooth ignition

-

steady blower start

-

quiet operation

-

no flickering lights (a sign of poor load balance)

📉 9. How Electrical Mistakes Waste Energy (and Money)

Bad wiring affects sustainability:

⚠️ Loose connections → heat → wasted power

⚠️ Undersized wires → resistance → wasted energy

⚠️ Overloaded circuits → motor stress → shorter heater lifespan

⚠️ Incorrect voltage → poor combustion performance

Efficient wiring = efficient heating.

📋 10. Savvy’s Electrical Safety Dance Checklist

Before closing the panel, confirm:

Panel & Load

✔ Panel has spare capacity

✔ Load calculation completed

✔ Breaker size matches heater requirements

Wiring

✔ Correct gauge

✔ Copper wire

✔ Clean conduit routes

✔ No sharp bends

Safety

✔ GFCI/AFCI compliance

✔ Grounding correct

✔ CSST bonding done

✔ No exposed conductors

Functionality

✔ Heater starts smoothly

✔ No breaker trips

✔ No buzzing or flickering

✔ Motor runs quietly

If everything checks out, your wiring is safe, efficient, and ready for years of service.

Final Savvy Takeaway

The Electrical Safety Dance isn’t about speed.

It’s about rhythm — the rhythm of safety, load balance, correct sizing, grounding, and clean planning.

When done right, you get:

-

steady heat

-

quiet operation

-

clean combustion

-

safe wiring

-

lower energy bills

-

longer heater lifespan

Electrical safety is sustainable safety.

And now you have Savvy’s complete system for mastering it.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Propane Like a Pro — Line Routing, Regulator Setup & Leak Testing for Ultra-Safe Operation