Propane is one of the cleanest, most efficient heating fuels — but only when installed correctly.

A perfectly routed propane line and a properly tuned regulator can give you:

-

smoother combustion

-

quieter operation

-

higher heating efficiency

-

lower emissions

-

longer component life

-

dramatically safer performance

A poorly planned propane system?

That’s where leaks begin, regulators freeze, heaters pulse, and efficiency drops.

Reznor UDX 60,000 BTU Propane Unit Heater

Savvy's philosophy is simple:

Propane rewards precision. The cleaner the routing and the smarter the regulator setup, the safer and more efficient your entire heater becomes.

This guide delivers a complete, eco-forward blueprint for routing propane lines, setting up regulators, and performing professional-grade leak testing — all at homeowner level.

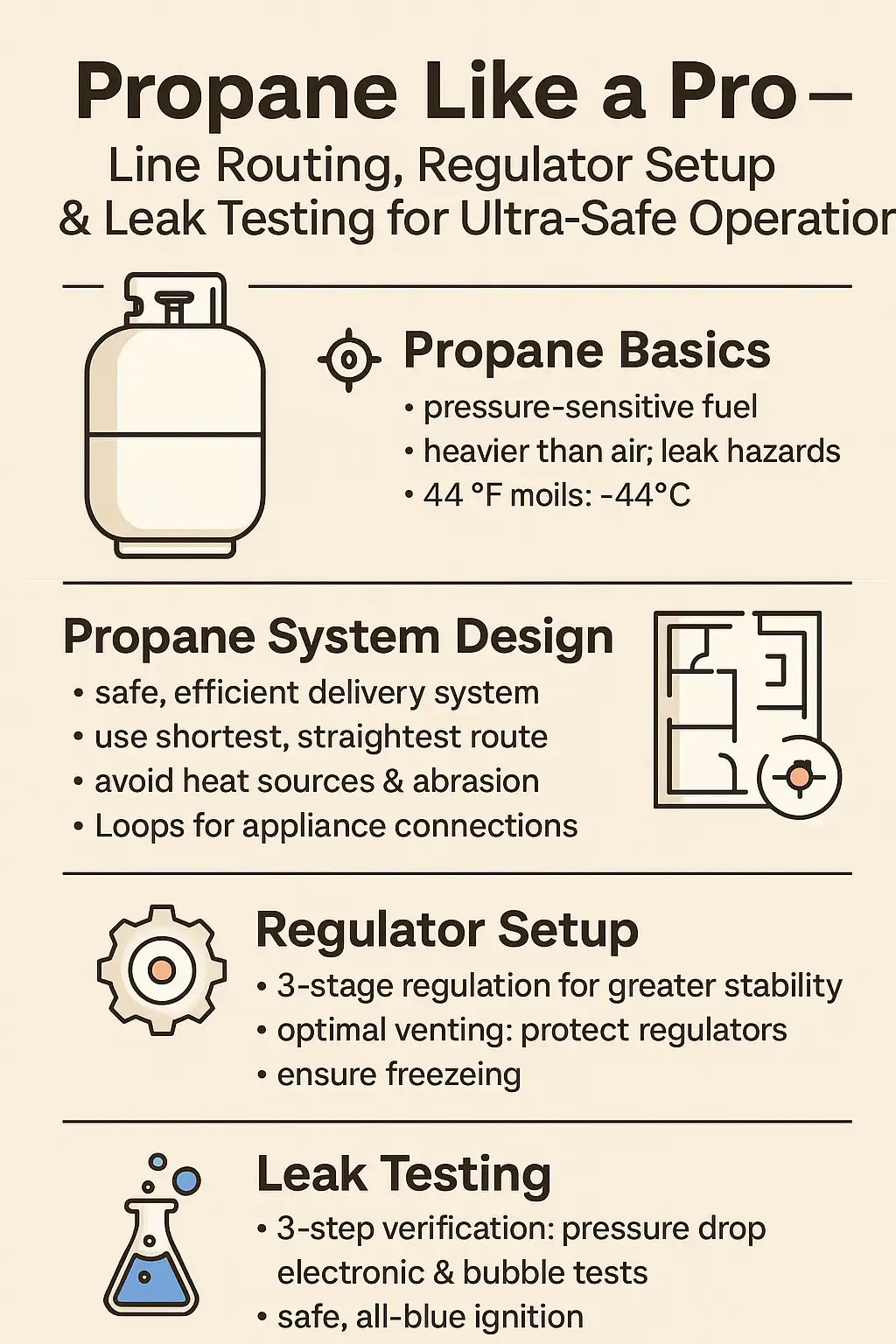

🧭 1. Propane Basics Every Installer Must Know (Before Touching a Wrench)

Understanding propane’s behavior makes every installation safer and more sustainable.

🧭 1.1 Propane Is Highly Efficient — But Pressure Sensitive

Propane boils at –44°F, turning from liquid to vapor. That vapor must reach your heater at the correct pressure to maintain:

-

blue, clean flame

-

proper BTU output

-

low emissions

-

quiet operation

Incorrect pressure = poor combustion.

Propane combustion basics:

https://www.propane.com

🧭 1.2 Propane Expands With Heat & Contracts With Cold

This affects:

-

regulator performance

-

line pressure

-

appliance ignition behavior

In cold climates, undersized or poorly routed lines reduce heater output dramatically.

🧭 1.3 Propane Is Heavier Than Air

This matters for safety:

-

leaks settle at low points

-

basements, pits, and low garages require special ventilation

-

leak detectors must be placed near floor level

EPA propane safety reference:

https://www.epa.gov/natural-gas-star-program

📐 2. Propane System Design — The Eco-Safe Blueprint

Let’s design a safe, efficient delivery system from tank to heater.

Propane systems have three major components:

-

The supply tank

-

The regulator system

-

The delivery line routing

A mistake in any one creates systemic issues.

📦 3. Choosing the Right Propane Line

You have three main options:

📦 3.1 Black Iron Pipe (Traditional, Very Durable)

Pros:

✔ extremely strong

✔ handles vibration

✔ fire-resistant

✔ long lifespan

Cons:

– requires threading tools

– heavy

– not flexible

This is the gold standard for rigid indoor runs.

📦 3.2 Copper Tubing (Allowed in Many States, Not All)

Pros:

✔ easier to install

✔ lightweight

✔ corrosion resistant

Cons:

– some states restrict use

– must use flare fittings (never compression)

Check local code before choosing copper.

📦 3.3 CSST (Corrugated Stainless Steel Tubing)

Pros:

✔ flexible

✔ fast installation

✔ ideally suited for complex routing

Cons:

– MUST be bonded for lightning safety

– more expensive

– susceptible to damage if not protected

📍 4. Propane Line Routing — The Savvy Precision Method

Routing lines is both engineering and art.

Savvy’s routing rules reduce:

-

vibration strain

-

leak risk

-

regulator freeze-ups

-

pressure drop

-

installation waste

📍 4.1 Rule #1: Keep the Run as Short as Possible

Every foot of line adds:

-

pressure loss

-

potential leak points

-

more fittings

Fewer fittings = safer system.

📍 4.2 Rule #2: Use Straight Paths, Avoid Excess Bends

Each elbow adds equivalent resistance to multiple feet of straight pipe.

This causes:

-

delayed ignition

-

flame instability

-

low BTU output

Aim for smooth, sweeping curves for flexible lines and minimal elbows for rigid lines.

📍 4.3 Rule #3: Avoid Heat Sources & Abrasion Points

Never route propane lines near:

-

furnace vents

-

exhaust pipes

-

hot surfaces

-

moving parts

-

saw stations or workbenches

Protect lines with:

-

conduit sleeves

-

wall plates

-

rubber grommets

📍 4.4 Rule #4: Anchor Lines at Regular Intervals

Loose lines vibrate.

Vibrating lines wear out fittings.

Worn fittings leak.

Use:

-

clamps

-

straps

-

isolation pads

Spacing recommendations:

-

Black iron: every 6–8 ft

-

Copper/CSST: every 3–4 ft

📍 4.5 Rule #5: Use Appliance Loops to Protect the Heater Connection

Create a gentle service loop of CSST or copper before connecting to the heater.

Benefits:

-

reduces stress on fittings

-

absorbs vibration

-

allows heater servicing

-

prevents metal fatigue

⚙️ 5. Understanding Regulators — The Heart of Propane Performance

A propane system without a properly sized and tuned regulator is like a car with no throttle control.

Regulators reduce tank pressure from 100–250 psi down to:

-

First-stage: ~10 psi

-

Second-stage: 11 inches WC (water column)

Most propane appliances require 11" WC.

⚙️ 5.1 Two-Stage Regulation — The Savvy Standard

Stage 1 Regulator (Tank Side)

Purpose: move vapor long distances

Pressure: 10 psi

Located at the tank.

Stage 2 Regulator (Building or Appliance Side)

Purpose: deliver appliance pressure

Pressure: 11" WC

Located near the house or heater.

Using two-stage is more stable, efficient, and safe.

NFPA propane regulator guidelines apply:

https://www.nfpa.org

⚙️ 5.2 Regulator Orientation Matters

Install regulators:

-

oriented upright

-

protected from weather

-

with drip legs to prevent freezing

-

with hood vents pointing downward

If a regulator becomes filled with water or snow → combustion instability happens.

⚙️ 5.3 Regulator Vent Protection

A regulator must breathe.

Block its vent and the entire system becomes unsafe.

Use a screened vent cap to prevent:

-

insects

-

dirt

-

ice

📏 6. Pressure Testing — The Science Behind Safe Combustion

A propane system must be pressure tested before use.

There are three types of testing:

-

Pressure Drop Test (PDT)

-

Electronic Leak Detection

-

Soap-Bubble Testing

All three create a complete safety picture.

🧪 7. Leak Testing Like a Pro (Savvy’s Three-Step Protocol)

🧪 Step 1 — Isolate & Pressurize the System

-

Close all appliance valves

-

Introduce nitrogen (never air!) to test pressure

-

Pressurize to test standard (often 10 psi)

Hold for required time (depends on local code).

🧪 Step 2 — Electronic Leak Detector Sweep

Use a propane-compatible electronic detector to check:

-

joints

-

valves

-

regulator housings

-

appliance connection

Electronic detection finds micro-leaks quickly.

🧪 Step 3 — Bubble Solution Test (Manual Verification)

A simple but reliable method:

-

apply bubble solution to all fittings

-

observe for growing bubbles

-

retighten or redo fittings as needed

Never use dish soap alone — it causes corrosion over time.

Use an HVAC-safe bubble solution.

🧯 8. Emergency Shutoff Strategy — Plan for Safety, Not Panic

A propane system must include:

✔ Tank shutoff

✔ Building shutoff

✔ Appliance shutoff

Each valve must be:

-

clearly visible

-

clearly labeled

-

easy to reach during emergencies

Install shutoff valves where you can reach them without climbing over the heater.

🧊 9. Cold Climate Considerations — Preventing Regulator Freeze-Up

In cold environments:

-

moisture enters regulators

-

propane vapor pressure drops

-

regulators freeze internally

Savvy solutions:

🧊 Install regulator covers

🧊 Use two-stage regulation

🧊 Keep vents pointed downward

🧊 Avoid low spots where water collects

Frozen regulators ruin efficiency and create ignition issues.

🔧 10. The Savvy Propane Start-Up Checklist

Before first ignition:

System

✔ correct pipe size

✔ clean routing

✔ anchored and protected

Regulator

✔ two-stage system

✔ vents protected

✔ correct orientation

Testing

✔ pressure test passed

✔ electronic leak test passed

✔ bubble test passed

Operation

✔ blue flame

✔ quiet burner

✔ stable ignition

If all boxes are checked → your system is safe, efficient, and ready.

🌿 11. Sustainability Benefits of Proper Propane Installation

A precise propane installation supports:

🌿 cleaner combustion

Fewer emissions from stable flame.

🌿 reduced leaks

Less propane wasted = lower environmental impact.

🌿 longer equipment life

Regulators and heaters run much longer when correctly routed.

🌿 lower energy bills

Efficient combustion burns less fuel per BTU produced.

🌿 minimal maintenance waste

Correct routing prevents future repairs.

Propane is already eco-efficient — Savvy installation makes it even better.

📋 12. Savvy’s Propane Like a Pro — Complete Homeowner Checklist

Line Routing

✔ shortest, smoothest path

✔ minimal fittings

✔ protected & anchored

✔ proper appliance loop

Regulator Setup

✔ two-stage system

✔ proper vent direction

✔ weather protection

✔ correct pressures

Leak Testing

✔ pressure drop test

✔ electronic detection

✔ bubble verification

Safety

✔ labeled shutoff valves

✔ CO detector installed

✔ no ignition sources nearby

Performance

✔ stable flame

✔ quiet operation

✔ consistent heating

Master these steps and your propane heater will deliver safer, cleaner, quieter, more sustainable heat for decades.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Smart Thermostat Pairings — Installing Controls That Cut Fuel Use Without Cutting Comfort