A precision-based combustion, airflow, electrical, and safety assessment designed to validate a heater installation before long-term operation begins.

Most HVAC problems don’t begin in year five — they begin in minute one.

When a new propane heater, shop heater, or garage unit heater starts up for the first time, it tells a story.

A story about:

-

airflow quality

-

combustion stability

-

vent drafting

-

regulator performance

-

electrical health

-

safety controls

-

install integrity

But many installers never “listen.” They simply flip the switch and leave.

Savvy knows better.

Your heater’s first seven minutes predict its next seven years.

The Burn Test Protocol is a structured, 7-minute diagnostic designed to ensure your installation is truly safe, efficient, quiet, and combustion-stable before you put hours or fuel into the system.

Reznor UDX 60,000 BTU Propane Unit Heater

This guide will walk you through the complete Savvy method — simple enough for homeowners, thorough enough for professionals.

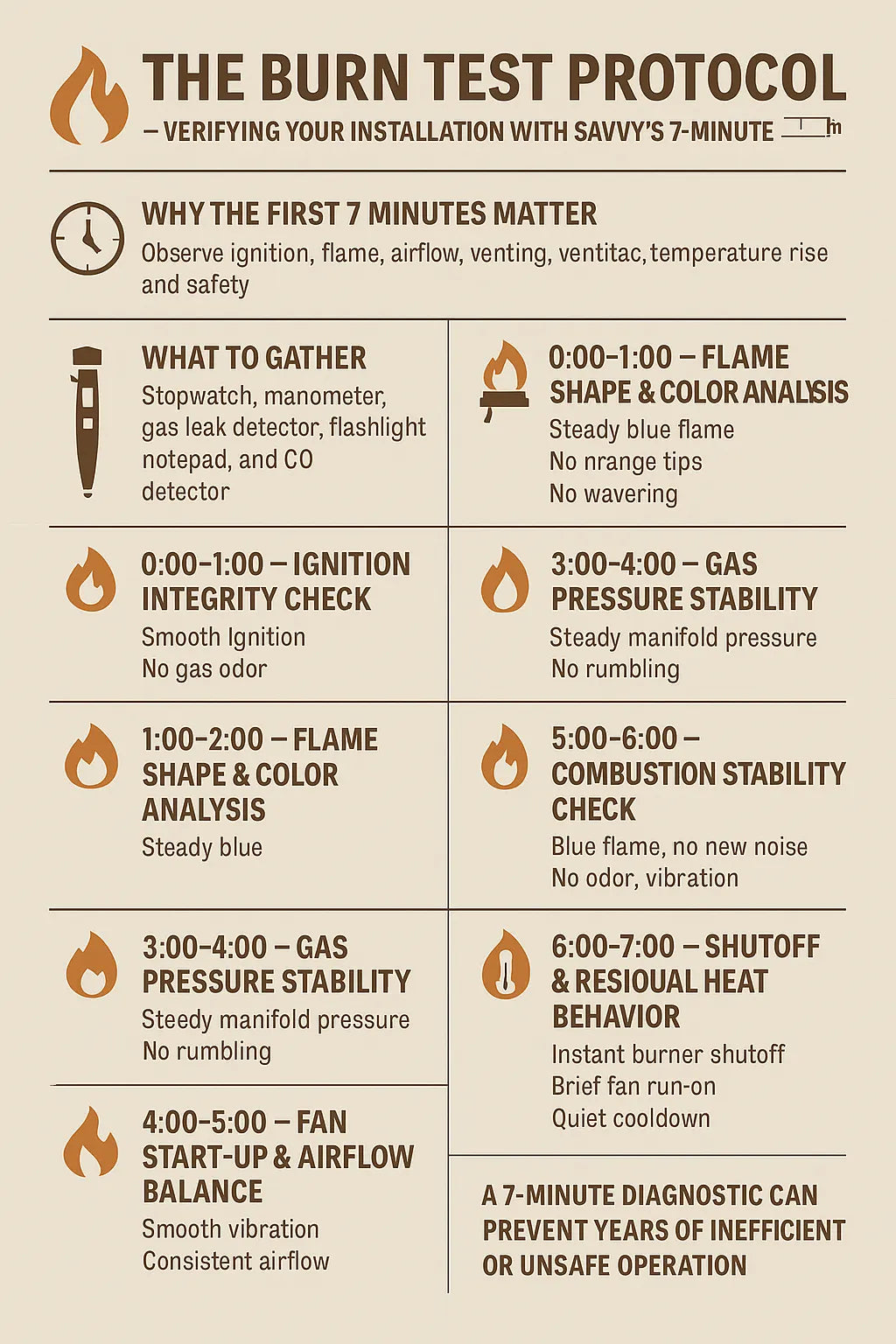

⏱️ 1. Why the First 7 Minutes Matter

In the first moments after startup, your heater transitions through:

1. Ignition

2. Flame stabilization

3. Early combustion tuning

4. Fan engagement

5. Vent equilibrium

6. Temperature rise

7. Safety verification

If anything is wrong with:

-

gas supply

-

vent slope

-

wiring

-

airflow

-

combustion air

-

pressure regulation

—you’ll detect it in these first 420 seconds.

DOE combustion safety reference

🛠️ 2. What You Need Before Running the Burn Test

To complete Savvy’s 7-Minute Protocol accurately, gather:

✔ Stopwatch or phone timer

✔ Manometer (optional but ideal)

✔ Electronic gas leak detector

✔ Flashlight

✔ Notepad

✔ Hearing awareness (listening matters!)

✔ CO detector nearby (required for safety)

EPA CO safety guidance:

https://www.epa.gov/indoor-air-quality-iaq

No specialized HVAC tools? You can still complete most steps visually and audibly.

🔥 3. Savvy’s 7-Minute Burn Test Protocol (Minute-By-Minute)

This is the signature sequence.

Start your timer the moment you power on or call for heat.

🔥 Minute 0:00–0:30 — Ignition Integrity Check

Listen for:

✔ Smooth ignition “whoomp”

Not explosive. Not delayed. Not repeated.

✔ No sulfur or “raw gas” smell

If detected: shut off immediately.

✔ Flame lights fully and consistently

Partial lighting = burner issues, air imbalance, or gas starvation.

What can go wrong here?

-

miswired igniter

-

incorrect gas pressure

-

air trapped in gas line

-

blocked burner ports

If ignition is delayed by more than 3 seconds, note it — this predicts future failure.

🔥 Minute 0:30–1:00 — Flame Shape & Color Analysis

Look through the flame observation window.

You're checking:

✔ Blue flame, steady and sharp

The ideal flame looks like a blue knife — not a candle.

✔ No orange tips

Indicates dust or improper air/fuel ratio.

✔ No wavering

Suggests vent pressure instability or intake blockage.

✔ Flame carries evenly across all burner ports

Uneven burn = bad alignment or clogged ports.

NFPA combustion references:

https://www.nfpa.org

If the flame “pulses,” your venting may be fighting your combustion.

🔥 Minute 1:00–2:00 — Vent Draft & Exhaust Behavior

Move to the vent termination (outside).

You're checking:

✔ Steady, warm exhaust flow

✔ No backdraft sensation

✔ No soot at termination

✔ No flapping noises from vent cap

✔ No visible vapor blowing back toward building

Backdraft risk increases dramatically if:

-

vent is too low

-

slope is incorrect

-

wind direction is ignored

-

intake & exhaust are too close together

If you feel exhaust being pushed back toward you → stop test and fix venting.

DOE venting resource: https://www.energy.gov/energysaver/ventilation

🔥 Minute 2:00–3:00 — Gas Pressure Stability (Optional: Manometer Test)

If you have a manometer, check manifold pressure during burner operation:

Propane heaters typically require:

-

10–11 inches WC (low pressure model)

-

Full BTU output requires stable pressure

You're looking for:

✔ No pressure drop after ignition

✔ No oscillation in reading

✔ Steady output with fan turning on

If you don’t have a manometer, listen for:

-

smooth, non-pulsing flame

-

no rumbling or roaring

-

no pitch change

Pressure instability causes noise instability.

🔥 Minute 3:00–4:00 — Fan Start-Up & Airflow Balance

Once the heat exchanger rises in temperature, the blower engages.

Listen and observe:

✔ Fan starts smoothly — no rattles

✔ No duct or casing vibration

✔ No metallic resonance

✔ Airflow feels consistent and not overly forceful

✔ No whistling or turbulence near intake

If the heater vibrates against its mount, add anti-vibration pads.

If airflow is weak, check:

-

filters

-

return path blockage

-

intake obstruction

-

incorrect thermostat settings

🔥 Minute 4:00–5:00 — Temperature Rise Validation

Place your hand:

-

in front of heater

-

several feet away

-

at shoulder level

You should feel a noticeable temperature difference.

Look for:

✔ Smooth warm-up

✔ No “cold blow” after initial heat

✔ Consistent temperature across output area

✔ No burning odor

(slight “new metal smell” is normal for first burn)

If temperature rise is slow, possible issues include:

-

weak gas pressure

-

vent blockage

-

incorrect regulator setup

-

oversized space

-

recirculation of cold air

🔥 Minute 5:00–6:00 — Combustion Stability Check (Mid-Burn)

At mid-cycle, the system stabilizes. This is when flaws reveal themselves.

Check:

✔ Flame still blue

✔ No new noise (“roaring” or “popping”)

✔ No vibration increase

✔ No odor

✔ Exhaust remains steady

If flame begins to flicker or turn orange this late in the test, you likely have:

-

pressure starvation

-

regulator icing

-

vent backpressure

-

indoor negative pressure

-

filter blockage

🔥 Minute 6:00–7:00 — Shutoff & Residual Heat Behavior

Turn the heater off at the thermostat.

Observe:

✔ Burner extinguishes instantly

Delay indicates gas valve wear or poor ignition control.

✔ Fan continues running briefly

This is healthy — removes heat from exchanger.

✔ No flame re-lighting

If flame returns momentarily, pressure is unstable.

✔ No banging noises

Indicates metal expansion issues or duct resonance.

✔ No backdraft smell

Residual exhaust being pulled in = bad drafting.

After fan turns off:

✔ The unit should cool quietly

Popping noises are normal for first few cycles, but loud bangs are not.

🌡️ 4. Burn Test Failure Indicators & What They Mean

Below is Savvy’s quick-diagnosis matrix.

❌ Symptom: Delayed ignition

Likely causes:

-

dirty igniter

-

wrong gas pressure

-

air in line

-

poor regulator output

❌ Symptom: Flame pulsing

Likely causes:

-

vent obstruction

-

intake blockage

-

pressure instability

-

negative indoor pressure

❌ Symptom: Orange flame

Likely causes:

-

dust

-

poor air/fuel mix

-

vent too short or too long

❌ Symptom: Loud blower

Likely causes:

-

vibration

-

unbalanced fan

-

heater mounted to hollow wall

❌ Symptom: Weak heat output

Likely causes:

-

low gas pressure

-

wrong regulator

-

incorrect pipe sizing

❌ Symptom: Exhaust smell indoors

Immediate shutdown required.

Backdraft or leak.

EPA indoor air safety:

https://www.epa.gov/indoor-air-quality-iaq

📦 5. Tools to Enhance Your Burn Test Results

Optional but extremely helpful tools:

✔ Infrared thermometer — track temperature rise

✔ Sound level meter — log noise levels

✔ Gas leak detector — verify joints

✔ CO detector — mandatory safety

✔ Anemometer — measure airflow

These tools give you professional-level insight.

🔧 6. Pre-Burn Test Checklist

Before starting, verify:

✔ All connections tightened

✔ All wiring secured

✔ Gas supply turned on

✔ Venting installed at correct slope

✔ Intake air path unobstructed

✔ Thermostat calling for heat correctly

✔ CO detector active

If everything checks out, begin the Burn Test.

📋 7. Savvy’s Official 7-Minute Burn Test Summary Checklist

Minute 0–1:

✔ Clean ignition

✔ Blue flame

✔ No smells

Minute 1–2:

✔ Stable flame

✔ No flicker

✔ Proper vent drafting

Minute 2–3:

✔ No pressure fluctuations

✔ No roaring

Minute 3–4:

✔ Smooth fan start

✔ No rattles

Minute 4–5:

✔ Strong temperature rise

✔ Even heat distribution

Minute 5–6:

✔ Quiet mid-cycle

✔ Blue flame maintained

Minute 6–7:

✔ Clean shutdown

✔ No backdraft

✔ Quiet cooldown

If any step fails, address the issue immediately — don’t run the system long-term until corrected.

🌿 8. Why This Protocol Improves Efficiency & Sustainability

Perfect installation = perfect combustion.

When the Burn Test verifies proper operation, you automatically get:

🌿 less propane wasted

🌿 lower emissions

🌿 longer heater life

🌿 fewer repairs

🌿 more consistent comfort

A 7-minute diagnostic can prevent hundreds of dollars in fuel waste per season.

🔥 Final Savvy Takeaway

The Burn Test Protocol is the last step of installation, but the first step of long-term performance.

Think of it as a new heater’s “health check.”

If the flame is stable, the exhaust is clean, the airflow is smooth, and the heater shuts down quietly — congratulations.

Your installation isn’t just correct.

It’s Savvy-certified.

Your heater will run cleaner.

Your home will stay safer.

Your fuel use will drop.

Your comfort will rise.

All because you spent 7 minutes listening to your system.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Condensate Without the Chaos — Installing Drains, Pumps & Neutralizers for Cold-Climate Propane Systems