Propane systems installed in cold climates require far more than heat, air, and venting.

They also require condensate management — the quiet, invisible system that prevents:

-

water damage

-

corrosion

-

freeze-ups

-

burner shutdowns

-

safety lockouts

-

acidic discharge

-

mold and structural decay

You can't run a high-efficiency propane appliance without removing condensate safely and responsibly.

And yet… condensate is often treated like an afterthought.

A hose thrown in a corner.

A pump plugged in wherever it fits.

A drain line routed “downhill-ish.”

Savvy says absolutely not.

Condensate is part of your fuel system.

When you manage it intentionally, your heater becomes cleaner, quieter, safer, and dramatically more durable.

Welcome to Condensate Without the Chaos — the definitive guide for homes, garages, shops, and outbuildings operating propane heaters in cold climates.

Reznor UDX 60,000 BTU Propane Unit Heater

💧 1. Why Propane Systems Produce Condensate (Especially in Cold Climates)

Condensate forms when hot exhaust cools rapidly, causing water vapor to condense.

High-efficiency propane appliances — direct-vent heaters, condensing furnaces, garage heaters — all create condensate because:

-

heat exchangers extract more energy

-

flue temperatures run cooler

-

exhaust loses heat in cold outdoor air

The colder the climate, the more condensate you produce.

Even non-condensing units can drip in freezing weather due to thermal shock inside the vent pipe.

DOE combustion efficiency reference:

https://www.energy.gov/energysaver/furnaces-and-boilers

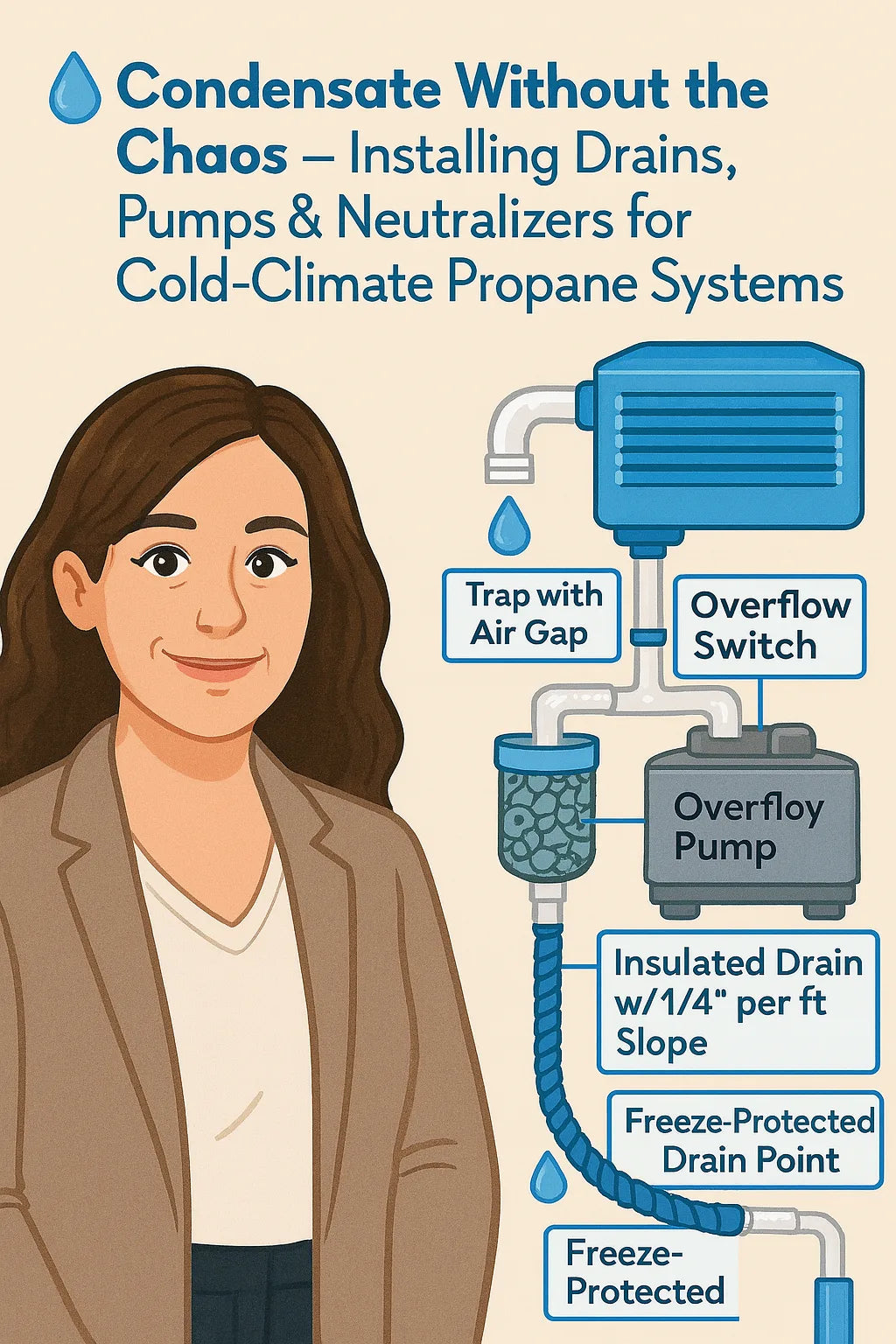

💧 2. The Three Components of a Chaos-Free Condensate System

Every safe, cold-climate propane installation uses ALL THREE components:

1️⃣ Drain Line

Moves water away safely.

2️⃣ Condensate Pump (when gravity won't do the job)

Provides elevation lift or long horizontal runs.

3️⃣ Neutralizer

Reduces acidity so water doesn't corrode pipes or harm septic systems.

EPA wastewater guidance:

https://www.epa.gov/septic

If any one piece fails, you get leaks, corrosion, freeze-ups, or appliance lockouts.

📐 3. Engineering the Perfect Condensate Drain Line

A condensate line is not “just a hose.”

It is a pressure-sensitive, freeze-prone, code-governed system.

Here’s how to build it right.

📐 3.1 Drain Line Slope — The Golden Rule of ¼ inch per foot

For gravity drainage:

-

Minimum slope: 1/4" per foot

-

Maximum recommended: 1" per foot

Too little slope = standing water.

Too much = splashing, noise, air gaps.

Always maintain continuous downward slope from the drain port to the exit point.

📐 3.2 Use Smooth-Wall PVC or CPVC — NOT Clear Vinyl Tubing

Clear vinyl:

-

kinks

-

traps algae

-

freezes easily

-

yellows and cracks

-

violates many cold climate guidelines

PVC/CPVC offers:

-

rigidity

-

freeze resistance

-

slope consistency

-

long-term reliability

📐 3.3 Trap Placement — Why It Matters

A condensate trap:

-

prevents flue gases from escaping

-

prevents vacuum lock

-

ensures water movement

-

protects indoor air quality

Many appliances include a trap, but if not:

-

install one within 6–12 inches of condensate outlet

-

never install multiple traps

-

never trap after a pump

Incorrect trapping causes:

-

gurgling

-

odor

-

shutdowns

-

pressure imbalance

📐 3.4 Freeze Protection Measures

Cold-climate lines must be protected:

✔ Insulate exposed lines

✔ Use heat tape on vulnerable sections

✔ Route indoors as long as possible

✔ Avoid exterior walls when possible

✔ Keep line lengths short

Even one frozen inch can stop the entire system.

📐 3.5 Termination Options

Approved discharge locations include:

-

floor drain

-

laundry standpipe

-

utility sink

-

condensate collection basin

-

approved exterior outlet (only if freeze-proofed)

Never drain onto:

-

sidewalks

-

driveways

-

soil without neutralization

-

walk paths where ice may form

⚙️ 4. Condensate Pump Design — Choosing the Right Model for Cold Climates

When gravity can’t carry water to a drain, a pump does the lifting.

But not all pumps are equal — especially the cheap ones.

Here’s what to look for.

⚙️ 4.1 Pump Lift Capacity

Typical lift requirements:

-

Basements: 8–15 ft

-

Garages: 4–12 ft

-

Shops/outbuildings: varies by layout

Pump must exceed your actual lift by at least 20%.

⚙️ 4.2 Cold-Climate Features You Should Demand

✔ Check valves rated for freezing conditions

Prevents backflow after shutdown.

✔ Thermal overload protection

Prevents burnout.

✔ Anti-siphon ports

Stops unintended suction.

✔ Insulated tank & housing

Reduces freeze risk.

✔ Backup overflow switch

Shuts off heater if pump fails.

⚙️ 4.3 Pump Placement Rules

Install the pump:

-

on a level surface

-

away from vibration

-

within 10 ft of heater

-

where noise won’t disturb

-

where you can access it

Never hide the pump behind walls or cabinetry.

⚙️ 4.4 Pump Drain Line Routing

Follow same slope rules as gravity lines, except allow:

-

uphill lift immediately after pump

-

downhill thereafter

Secure the line every 3–4 ft to avoid sagging.

🧪 5. Neutralizers — The Eco-Responsible Upgrade Most Homeowners Ignore

Condensate pH often ranges from 3.0 to 4.5 — acidic enough to:

-

damage concrete

-

corrode metal

-

ruin septic systems

-

poison lawns

Neutralizers solve this problem.

🧪 5.1 What Neutralizers Contain

Typically:

-

limestone (calcium carbonate)

-

magnesium oxide

-

calcite media

These react with acidic condensate to raise pH to a safe 6–8.

Reference:

https://www.energystar.gov (efficiency + environmental standards)

🧪 5.2 When a Neutralizer Is Required

You MUST use a neutralizer if:

-

draining outdoors

-

draining to septic

-

draining into copper or steel pipes

-

required by code in your jurisdiction

Even if not required, Savvy recommends it.

🧪 5.3 How to Install a Neutralizer

Install:

-

In-line after trap

-

Before any pump (to protect pump internals)

-

Level and accessible

-

With unions on both ends for easy replacement

Replace media every 12–24 months depending on usage.

❄️ 6. Cold-Climate Condensate Engineering — Where Most Installers Fail

When temps drop below freezing, condensate becomes a hazard.

Here’s how to stay ahead of winter chaos.

❄️ 6.1 Avoid Exterior Drain Runs Whenever Possible

Exterior lines freeze unless heat-taped and insulated perfectly.

Interior routing is always the preferred method.

❄️ 6.2 Heat Tape Application

Use:

-

UL-listed heat tape

-

self-regulating models

-

wrap on PVC only (not vinyl)

-

plug into GFCI outlet

Never overlap heat tape over itself.

❄️ 6.3 The Heated Pump Option

In unheated garages or pump rooms, use a pump with:

-

built-in tank heater

-

insulated housing

These keep water above freezing when the heater is off.

❄️ 6.4 Overflow Safety Switches

Overflow switches protect your heater from water-related shutdowns by cutting power if the pump tank fills.

A frozen drain line without an overflow switch will flood the heater — or the floor.

Always connect the overflow switch inline with thermostat or safety terminal.

🔍 7. Condensate Troubleshooting Before It Becomes Chaos

Here’s Savvy’s rapid diagnostic matrix.

🔍 Symptom: Water pooling near heater

Cause: cracked or loose drain line

Fix: replace & secure properly

🔍 Symptom: Gurgling noises

Cause: incorrect trap height or missing trap

Fix: reinstall correctly

🔍 Symptom: Pump running constantly

Cause: float stuck, check valve leaking

Fix: clean or replace pump/check valve

🔍 Symptom: Freezing in drain line

Cause: line routed externally

Fix: reroute indoors or heat-tape

🔍 Symptom: Corroded pipes or concrete

Cause: unneutralized condensate

Fix: install neutralizer ASAP

🔍 Symptom: Musty smell

Cause: algae buildup

Fix: flush with vinegar solution (never bleach)

📋 8. Savvy’s Perfect Condensate System Checklist

Drain Line

✔ ¼" per foot slope

✔ no vinyl tubing

✔ trap installed correctly

✔ freeze-protected

✔ secure clamps every 3–4 ft

Pump

✔ correct lift capacity

✔ overflow safety switch

✔ anti-siphon protection

✔ insulated in cold climates

✔ easy access

Neutralizer

✔ installed before pump

✔ unions for servicing

✔ media replaced annually

✔ pH output 6–8

Cold Climate Safety

✔ heated lines where needed

✔ insulated pipes

✔ no exterior routing

✔ no droops or sags

If everything is checked, your system is condensate chaos-proof.

🌿 9. Sustainability Benefits of a Well-Designed Condensate System

A perfectly designed condensate system reduces environmental impact dramatically.

🌿 protects soil and groundwater

(acidic condensate becomes neutralized)

🌿 reduces heater corrosion

(less metal waste over time)

🌿 prevents pump failures and replacements

(less e-waste)

🌿 enables higher-efficiency appliances

(condensing units rely on proper drainage)

🌿 reduces energy waste

(systems don’t short-cycle due to drain blockages)

A chaos-free condensate system is a climate-friendly system.

🔚 Final Savvy Takeaway

Condensate lines aren’t “extra plumbing.”

They are structural components of your heating system’s long-term health.

A poorly routed or unprotected condensate line can stop your entire heater in its tracks — especially in freezing climates.

But when you design with intention:

-

correct slope

-

freeze protection

-

smart pump selection

-

pH neutralization

-

clean routing

…your propane heater becomes a silent, safe, sustainable powerhouse that runs without leaks, without odors, without pump failures, without corrosion — and without the chaos.

Buy this on Amazon at: https://amzn.to/4oCrGcV

In the next topic we will know more about: Propane-First Planning — Designing a Safe, Sustainable, Low-Emission Install from Day Zero