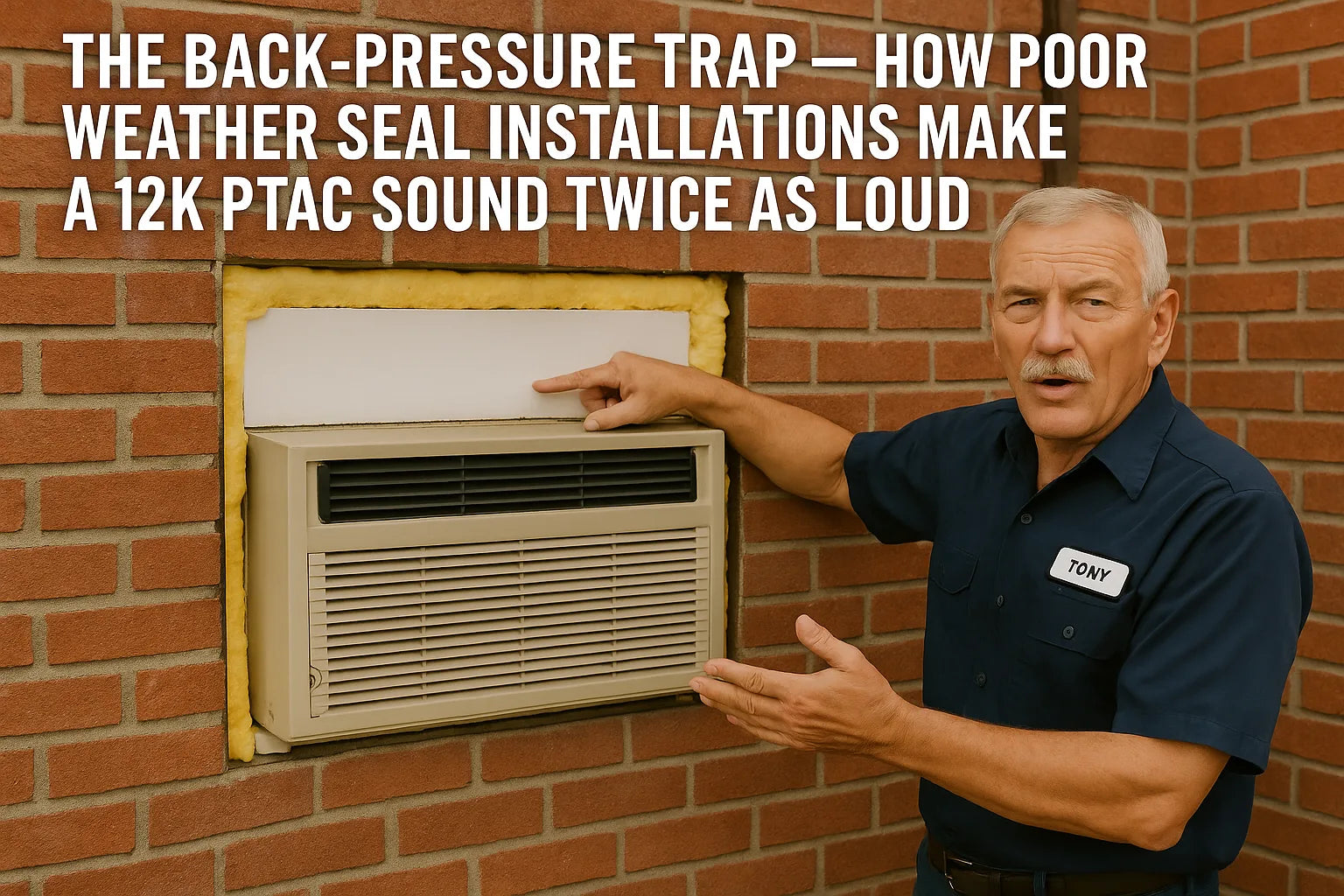

By Tony Marino — “Noise isn’t a mystery. It’s pressure fighting to get out.”

There’s a moment every HVAC tech knows—the customer calls and says:

“Tony, this PTAC is way louder than the last one. It sounds like a jet engine.”

And here’s what I always tell them:

“If you installed it right but didn’t seal it right,

you didn’t install it right.”

Because a badly sealed PTAC — especially a 12,000 BTU model with a 3.5 kW heat kit — doesn’t just leak air.

It creates back-pressure, and back-pressure is the silent killer of quiet PTAC operation.

The blower tries to move air…

The air tries to go somewhere…

The seal won’t let it…

And now the blower sounds like it’s fighting a losing battle underwater.

Amana Distinctions Model 12,000 BTU PTAC Unit with 3.5 kW Electric Heat

This article breaks down the real mechanics behind the noise — the Tony way.

🔊 1. Why a PTAC Gets Loud: It's Almost Always Back-Pressure, Not the Blower

Most people think a loud PTAC means:

-

The fan is bad

-

The motor is weak

-

The bearings are worn

-

The blower wheel is hitting

-

The unit is defective

Nope.

95% of PTAC noise complaints come from bad weather sealing.

Why? Because a PTAC is designed to breathe.

It needs a clean pressure path:

-

Indoor airflow → blower → coil → outdoor compartment

-

Outdoor airflow → coil → blower discharge → grille

But when you install a PTAC sleeve and use:

-

Overstuffed foam

-

Wrong-density insulation

-

Caulk in the wrong place

-

Blocked air paths

-

Cheap weather stripping

-

Too much expansion foam

-

The wrong exterior grille angle

-

Gaps causing turbulence

The air has nowhere to go.

Pressure builds.

Noise skyrockets.

Vibration resonates.

Blower RPM goes unstable.

The compressor even sounds louder because pressure waves distort the acoustics.

A weather-seal mistake amplifies every sound the PTAC makes.

🧱 2. Understanding the “Pressure Box” the PTAC Lives In

A PTAC doesn’t sit in open air like a mini split.

It sits in a pressure box — the sleeve.

The sleeve has:

-

An outdoor compartment

-

An indoor compartment

-

A divider

-

Drain paths

-

Pressure relief channels

When you close that box with bad weather sealing, you create:

🎯 1. Pressure reflections

Sound waves bounce and amplify.

🎯 2. Aerodynamic turbulence

Airflow smashes into foam or gaps.

🎯 3. Return-air starvation

Blower speed ramps up to compensate.

🎯 4. Increased ESP (external static pressure)

Even +0.1” WC will double perceived noise.

🎯 5. Venturi effect through gaps

Whistling, hissing, or “sucking” sounds.

Back-pressure is basically “air trying to escape through mistakes.”

🌀 3. The Most Common Weather Seal Mistake: Over-Foaming the Sleeve

Installers love spray foam.

They trust it too much.

Spray foam is the #1 cause of PTAC back-pressure noise.

Why?

Because they fill three areas that should NEVER be filled:

❌ A. The top of the sleeve (blocks pressure relief)

This should NEVER be sealed completely.

It must remain a flexible pressure buffer.

❌ B. The lower drain area (restricts exhaust airflow)

Blocking this creates water retention + pressure bounce.

❌ C. The airflow return paths (causes blower starvation)

Even a slight foam intrusion narrows the path and creates noise.

The Tony Rule:

“Seal the drafts, not the airflow.”

Spray foam is only for the rough opening, not the air path.

If it expands into the sleeve, the unit gets louder instantly.

🔍 4. How to Tell If Back-Pressure Is the Culprit (Tony’s 30-Second Test)

Want to diagnose in 30 seconds?

Do this:

Step 1 — Turn the PTAC to high fan

Listen to the blower noise.

Step 2 — Open the front intake grille

If the noise drops instantly?

Your return path is starving.

Step 3 — Pull the chassis out 2 inches

If noise drops significantly?

Back-pressure or sleeve sealing is wrong.

Step 4 — Remove the outdoor grille

If that quiets the unit?

The grille angle or seal is restricting exhaust path.

Step 5 — Check the foam around the sleeve

If you see ANY foam inside the sleeve?

That’s your noise amplifier.

🧰 5. Where Weather Seals MUST Go (And Where Tony Never Lets Them Go)

Let’s break this down cleanly.

✔ Where Seals MUST Be Installed

These areas require a proper seal to stop drafts:

-

The perimeter of the rough opening

-

The metal-to-drywall boundary

-

The gap between sleeve and wall

-

The top corners (only lightly)

-

The exterior flange to stop water intrusion

-

Any location where conditioned air meets unconditioned air

These seals prevent:

-

Outdoor air infiltration

-

Insects

-

Water intrusion

-

Thermal bleed

❌ Where Seals Must NEVER Be Installed

Tony forbids sealing in these areas:

-

Behind the PTAC chassis

-

Below the drain pan

-

Around the condenser discharge

-

Across the sleeve’s top airflow relief

-

In the interior path between blower and coil

-

Over the return-air leak points that the unit needs to breathe

Sealing these creates:

-

Restricted airflow

-

Turbulence

-

Back-pressure

-

Negative pressure pockets

-

Compressor resonance

-

Loud blower whine

-

Chattering louvers

-

Heat kit cycling

-

Boosted static pressure (ESP)

If you’ve ever heard a PTAC that sounds like:

-

A plane taking off

-

A box fan in a closet

-

A vacuum cleaner

-

A whistling vent

-

A motor struggling

It was sealed wrong.

🧲 6. Why a 12k PTAC Is More Sensitive to Back-Pressure Than Other Models

A 12,000 BTU PTAC typically moves:

-

350–420 CFM

-

Through a small sleeve opening

-

With a compact condenser coil

-

And a small-path blower housing

This means:

-

Smaller airflow paths = higher sensitivity

-

Slight restriction creates huge pressure gain

-

Noise curve increases exponentially

A 9k PTAC?

Not as sensitive.

A mini split?

Totally different airflow architecture.

But a 12k PTAC in a sleeve is like a turbocharged engine in a small hood:

If you block anything, you’ll hear everything.

🛠️ 7. The Exterior Grille: The Hidden Noise Amplifier Nobody Checks

90% of installers never touch the grille after installing it.

Here’s Tony’s rule:

“If the grille’s not angled right, the system’s not breathing right.”

Common grille mistakes:

-

Wrong grille model

-

Wrong slope

-

Wrong louver direction

-

Gaps causing turbulence

-

Pressure bounce from brick walls

-

Grille not fully seated

-

Bent louvers

This is a HUGE noise contributor.

💨 8. Air Turbulence: The Real Reason a Poor Seal Makes Noise Louder

This part is important.

Noise isn’t just the blower itself.

It’s what the blower does to the air when air is restricted.

Bad seals cause:

1. High-pressure air hitting foam

Makes a roaring sound.

2. Pressure waves bouncing around the sleeve

Amplifies motor noise.

3. Whistle noise from small gaps

Air rushing through tiny openings.

4. Turbulence at the drain level

Creates rumbling or droning.

5. Resonance

The sleeve acts like a speaker box.

A 12k PTAC is basically a fan, coil, and compressor inside a metal cavity.

Bad sealing turns that cavity into a sound amplifier.

🧪 9. Tony’s Back-Pressure Fix Checklist

Here’s the exact process Tony uses to eliminate noise.

✔ Step 1 — Remove the PTAC chassis

Check the sleeve for:

-

Foam intrusion

-

Obstructed corners

-

Blocked drain paths

-

Foam near condenser discharge

Fix anything wrong.

✔ Step 2 — Re-cut the weather seals

Use closed-cell foam, not open-cell.

Closed-cell = doesn’t absorb water

Open-cell = absorbs and expands unpredictably

✔ Step 3 — Re-seal only the rough opening

Not the airflow.

✔ Step 4 — Test the outdoor grille angle

Adjust until airflow breathes freely.

✔ Step 5 — Use Tony’s “Dollar Bill Test”

Slide a dollar bill through airflow paths:

If it catches ⇒ airflow is restricted

If it slides freely ⇒ path is open

✔ Step 6 — Reinstall chassis and measure ESP

You want:

-

0.05–0.10” WC max

More than that = back-pressure present.

📚 10. External Verified Links (Backed by Real Standards)

Here are reliable resources that align with best practices mentioned in this guide:

-

Energy.gov – Air Sealing Guidelines

https://www.energy.gov/energysaver/air-sealing-your-home -

OSHA – Construction Saw Safety (for proper wall cuts)

https://www.osha.gov -

International Building Code (Wall Framing Requirements)

https://codes.iccsafe.org/ -

UL Guidelines for Electric Heat Components

https://ul.com/ -

ASHRAE Handbook – HVAC Fundamentals (Airflow & Pressure)

https://www.ashrae.org/technical-resources/ashrae-handbook

These align directly with the airflow, pressure, and sealing standards Tony follows.

🏁 Final Word From Tony

A PTAC getting louder isn’t the unit “working harder.”

It’s the airflow fighting back.

You didn’t block the fan.

You didn’t block the coil.

You blocked the pressure path with a bad weather seal — and now the system’s yelling about it.

Fix the seals, and you fix the sound.

Fix the pressure, and you fix the performance.

PTACs don’t get loud on their own.

Humans make them loud.

Tony fixes them.

Buy this on Amazon at: https://amzn.to/3WuhnM7

In the next topic we will know more about: Stop Pushing Warm Air Into a Muddy Hole — Tony’s Condensate Rule That Saves Floors, Carpets, and Drywall