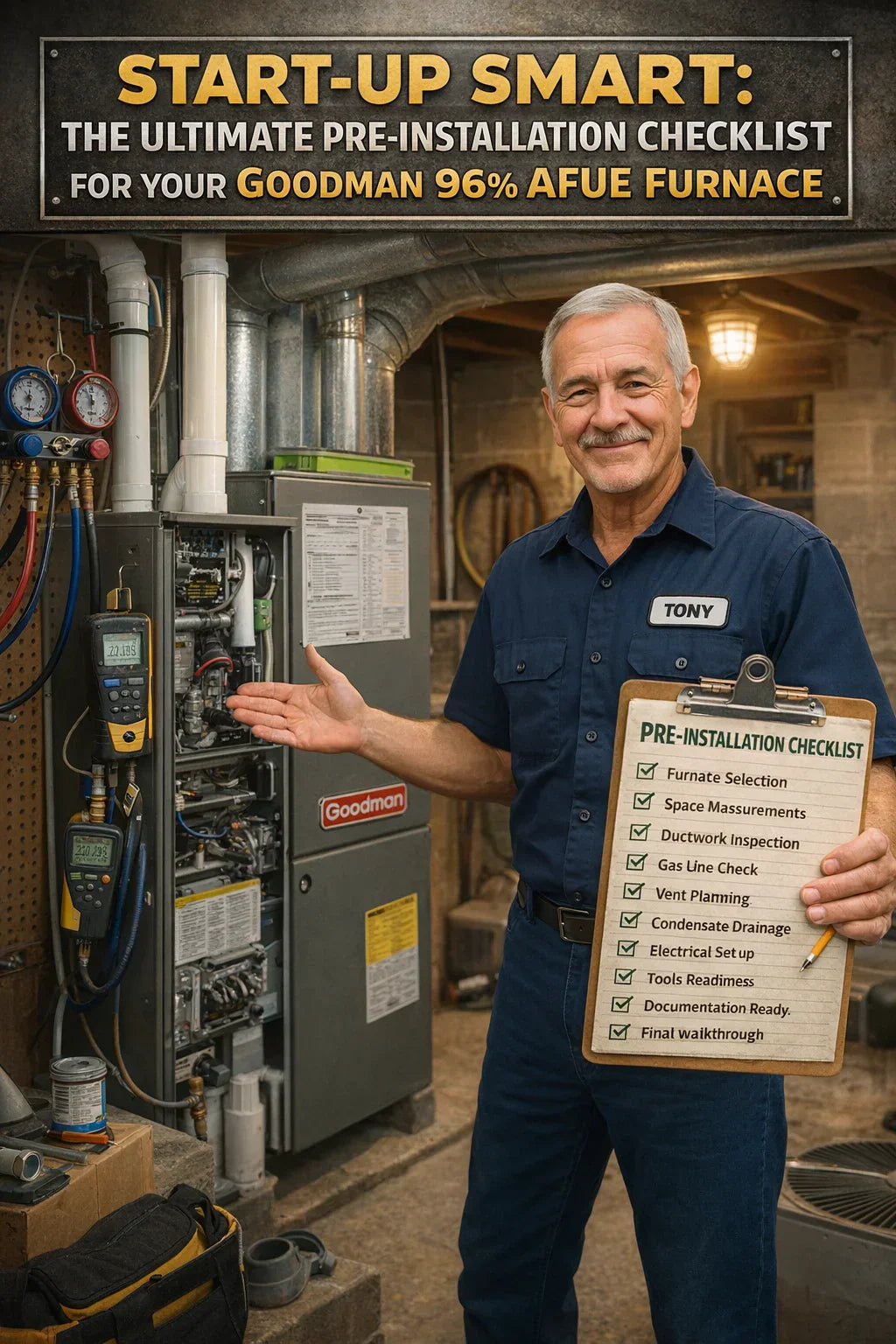

Tony here. Let me say this upfront:

Most furnace problems don’t start at start-up — they start before the furnace ever gets set in place.

I’ve seen brand-new, high-efficiency furnaces blamed for noise, short-cycling, lockouts, and high gas bills when the real issue was sloppy prep. The Goodman 96% AFUE 100,000 BTU two-stage furnace is a solid machine — but it only performs as well as the system it’s installed into.

This guide is your pre-installation checklist. Not the manufacturer’s bare-bones version — the real-world one installers use when they don’t want callbacks.

If you get this right, start-up becomes boring. And boring is good.

📦 Step 1: Confirm You Bought the Right Furnace (Before the Truck Arrives)

Before you touch a wrench, verify the equipment is actually correct for the job.

The Goodman 96% AFUE 100,000 BTU two-stage furnace in a 21-inch cabinet is designed for medium-to-large homes, tighter envelopes, and modern duct systems.

Double-check:

-

BTU output matches the home’s heat load (not the old furnace size)

-

Cabinet width fits your mechanical space

-

Orientation (upflow or horizontal) matches the install plan

-

Gas type is natural gas (not propane unless converted)

👉 Product reference:

If the furnace doesn’t physically fit or match the application, no amount of start-up magic fixes that.

📐 Step 2: Measure the Space Like a Pro (Clearances Matter)

High-efficiency furnaces need room to breathe, drain, and be serviced.

Minimum checks before install:

-

Front clearance for blower removal

-

Side clearance for gas valve and wiring access

-

Top clearance for vent connections

-

Floor support (especially in horizontal installs)

I’ve pulled furnaces back out because someone “eyeballed” clearances instead of measuring. Don’t be that guy.

Tony rule:

If a tech can’t remove the blower without uninstalling the furnace, the install is already wrong.

🌬️ Step 3: Inspect the Ductwork Before You Blame the Furnace

Two-stage furnaces expose bad ductwork fast.

Before install, inspect:

-

Return size vs furnace airflow requirements

-

Supply plenum size and transitions

-

Existing restrictions (old dampers, crushed flex, undersized returns)

-

Filter location and size

This furnace uses a 9-speed ECM blower. That blower will try to move air — but if the duct system is choking it, you’ll get noise, limit trips, and comfort complaints.

Checklist item:

-

Verify return duct can handle low-stage and high-stage airflow without exceeding static pressure limits

If you don’t own a manometer, stop here and get one.

🔥 Step 4: Verify the Gas Supply Before You Set the Furnace

This is where most installs quietly fail.

Before install:

-

Confirm gas line size supports 100,000 BTUs

-

Measure available gas pressure

-

Inspect shutoff valve placement

-

Check sediment trap (drip leg) location

A furnace starved for gas won’t trip immediately — it’ll run just badly enough to cause nuisance issues later.

Tony truth:

A perfect furnace on a bad gas line is still a bad system.

🧱 Step 5: Plan the Venting System — Don’t Reuse Old Mistakes

This Goodman is a condensing furnace. That means PVC venting, correct pitch, and proper termination.

Pre-install vent checklist:

-

Verify allowed vent pipe material (PVC, CPVC, or polypropylene)

-

Measure total equivalent vent length

-

Plan proper slope back to furnace

-

Confirm intake and exhaust termination locations

-

Check local code for clearances from windows and doors

Never assume the old venting is acceptable just because the old furnace “worked.”

👉 Manufacturer reference:

https://www.goodmanmfg.com/products/gas-furnaces

💧 Step 6: Condensate Drain Planning (Where Most People Get Lazy)

Condensing furnaces make water. That water must leave — every time, in every condition.

Before install:

-

Identify a gravity drain or pump location

-

Plan trap installation

-

Ensure freeze protection in cold spaces

-

Verify drain slope (¼″ per foot minimum)

If the drain is an afterthought, the service call is guaranteed.

Tony rule:

No drain plan = no start-up.

⚡ Step 7: Electrical and Control Prep

This furnace is smart — but only if it’s wired correctly.

Pre-install electrical checks:

-

Dedicated circuit available

-

Correct breaker size

-

Proper grounding

-

Clear routing for thermostat wire

-

Thermostat compatibility with two-stage heat

Don’t cheap out on the thermostat. Two-stage furnaces shine when staging is controlled properly.

🧰 Step 8: Tools You Should Have Before Installation Day

If you don’t have these on site, you’re not ready for start-up.

Minimum tool list:

-

Combustion analyzer

-

Digital manometer

-

Multimeter

-

Level (yes, really)

-

Drill with proper vent bits

-

PVC cement rated for flue gas temps

Borrowed tools lead to skipped steps. Skipped steps lead to callbacks.

📋 Step 9: Pre-Start Documentation and Setup

Before the furnace ever fires:

-

Register the warranty

-

Review installation manual (yes, actually read it)

-

Verify conversion kits if applicable

-

Document baseline measurements

This takes 15 minutes. It saves hours later.

✅ Step 10: The “Ready for Start-Up” Final Walkthrough

Before first ignition, walk the system:

✔ Furnace is level

✔ Gas line tested

✔ Venting glued, pitched, and supported

✔ Drain trapped and tested

✔ Duct connections sealed

✔ Filter installed

✔ Thermostat wired correctly

If every box is checked, start-up becomes simple.

🔚 Final Tony Takeaway

The Goodman 96% AFUE two-stage furnace doesn’t need babysitting — it needs preparation.

Most “problem furnaces” are victims of rushed installs, ignored ductwork, and lazy planning. Do the work before the install, and start-up becomes the easiest part of the job.

In HVAC, the system doesn’t forgive shortcuts — it invoices them.

🔗 External References

-

Goodman Gas Furnace Product Line

https://www.goodmanmfg.com/products/gas-furnaces - U.S. Department of Energy – Furnaces & Boilers

https://www.energy.gov/energysaver/furnaces-and-boilers