When you’re investing in a 7.5 Ton packaged AC and gas furnace unit for your business, you’ll hear a lot about single-stage vs. two-stage systems. At first, it sounds like HVAC sales jargon — but the choice can have a big impact on your comfort, energy bills, and long-term ROI.

So, which one is right for you? Let’s break it down Tony-style: simple, practical, and with real-world examples.

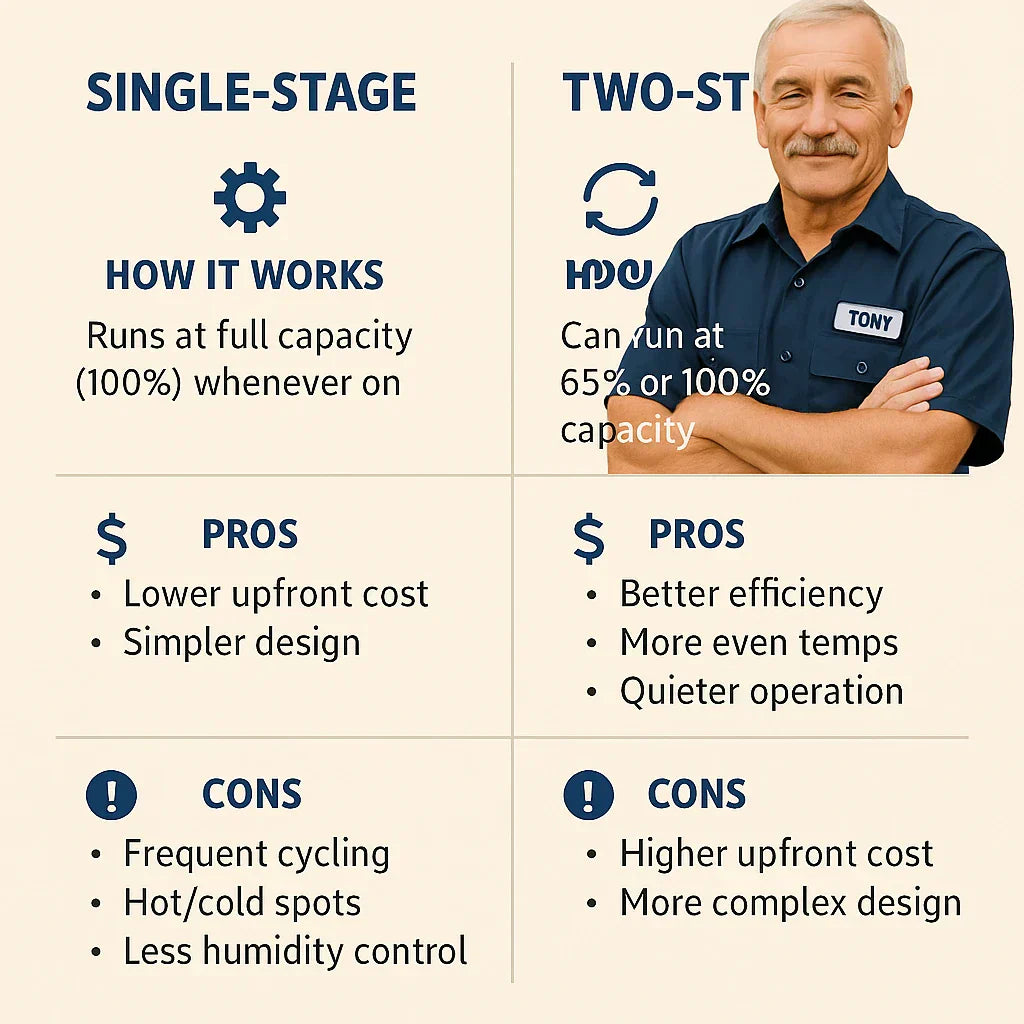

⚙️ What Is a Single-Stage System?

A single-stage packaged system has a compressor that runs at full blast (100%) every time it turns on.

-

On or off. No in-between.

-

Cheaper to buy upfront.

-

Easier to repair and maintain.

-

But: It short cycles in mild weather (lots of on-off action), which means:

-

Wasted energy

-

Uneven temperatures

-

Less humidity control

-

👉 Tony’s analogy: A single-stage system is like driving a car that can only go 70 mph or 0 mph. Great for the highway, not so smooth in stop-and-go traffic.

🔄 What Is a Two-Stage System?

A two-stage packaged system has a compressor that can run at:

-

Low stage (~65% capacity) → handles mild days and partial loads.

-

High stage (100% capacity) → kicks in for hot summer afternoons or heavy occupancy.

That means:

-

Longer, steadier run times.

-

Better humidity control.

-

Quieter operation.

-

More consistent temperatures across large spaces.

📌 According to Carrier Commercial HVAC, part-load efficiency is where businesses save the most money, since HVAC systems rarely run at 100% all day.

👉 Tony’s analogy: A two-stage system is like having both cruise control and full throttle in your car. Smooth most of the time, power when you need it.

💲 Upfront Cost Comparison

Let’s talk dollars.

-

Single-stage 7.5 ton unit: $10,000–$13,000 (equipment only).

-

Two-stage 7.5 ton unit: $12,000–$15,000 (equipment only).

👉 Difference: About $1,500–$3,000 more for a two-stage system.

Installation costs (labor, crane, permits) are basically the same. The price gap is in the equipment itself.

📌 HVAC cost guide confirms two-stage units carry higher upfront prices but can reduce long-term operating costs.

🌡️ Comfort Differences in Real Spaces

Here’s where the rubber meets the road: How does each system feel in your building?

🛍️ Retail Store (5,000 sq. ft.)

-

Single-stage: Customers near the door get blasted with cold air, while the back stays warm. System short-cycles in spring/fall.

-

Two-stage: Runs steady at low stage, keeping temps even across the store.

🍽️ Restaurant (3,800 sq. ft. with open kitchen)

-

Single-stage: Dining room fluctuates between hot and cold as the system cycles. Kitchen heat overwhelms system at peak times.

-

Two-stage: Stays ahead of kitchen loads by running long, steady cycles. Diners barely notice the system.

🏥 Medical Office (4,200 sq. ft.)

-

Single-stage: Exam rooms get stuffy between cycles. Patients complain.

-

Two-stage: Quiet, consistent comfort — ideal for sensitive spaces.

👉 Tony’s verdict: If comfort matters to your customers or patients, two-stage is worth the extra spend.

⚡ Energy Efficiency Impact

Efficiency ratings are another key difference.

-

Single-stage units: Typically meet minimum DOE standards (around 13.0 IEER2 for 2025).

-

Two-stage units: Often achieve higher IEER2 ratings (14.0–15.0+), especially at part-load.

📌 DOE Appliance Standards confirm that efficiency minimums have risen, making two-stage units more attractive for long-term compliance.

👉 Example:

-

Old 10 IEER unit: $8,000/year cooling costs.

-

Single-stage 13 IEER2: $7,000/year.

-

Two-stage 14.8 IEER2: $5,600/year.

Savings: $1,400/year → $14,000 over 10 years.

📌 Trane highlights that part-load efficiency is where businesses save the most.

🛠️ Maintenance Considerations

-

Single-stage:

-

Fewer components.

-

Simpler repairs.

-

Slightly lower maintenance costs.

-

-

Two-stage:

-

More complex compressor.

-

Parts may cost more if they fail.

-

But: Modern systems are reliable, and warranties often cover key parts.

-

📌 ASHRAE notes that preventative maintenance is critical for both types — neglect cancels out efficiency gains either way.

📊 Real-World ROI Examples

Example 1: Office Building (5,000 sq. ft., 10-hour days, 6 days/week)

-

Single-stage annual cooling cost: $7,200

-

Two-stage annual cooling cost: $5,800

-

Difference: $1,400 per year

-

Payback: ~2 years on higher upfront cost

Example 2: Restaurant (3,500 sq. ft., high internal load)

-

Single-stage: Constant cycling, hot/cold complaints → customers unhappy.

-

Two-stage: Comfort improves = better dining experience → indirect revenue boost.

Example 3: Retail Store (4,500 sq. ft.)

-

Single-stage: Cheaper upfront, fine if open only 6 hours/day.

-

Two-stage: Better long-run savings if operating 12+ hours/day.

✅ Tony’s Take: Which Should You Choose?

Here’s my no-nonsense breakdown:

-

Pick single-stage if…

-

You’re on a tight budget.

-

Your building is under 4,000 sq. ft..

-

Occupancy and heat loads are pretty stable.

-

-

Pick two-stage if…

-

You run long hours (10+ per day).

-

Your building has variable occupancy (restaurants, retail).

-

Comfort is critical (medical, customer-facing spaces).

-

You want lower utility bills over the next decade.

-

📌 Final Word from Tony

When it comes to single-stage vs. two-stage packaged systems, it’s not about fancy HVAC jargon — it’s about how your business actually runs.

-

If you just need the cheapest install today, single-stage will work.

-

But if you want better comfort, quieter operation, and lower bills, a two-stage system is the smarter long-term play.

My advice? Run the numbers. Look at your operating hours, utility rates, and how important comfort is to your customers and staff. More often than not, a two-stage system pays for itself.

In the next topic we will know more about: Noise Levels Explained: How Quiet Is the Daikin 7.5 Ton Packaged Unit?