If you’ve got a business to run, the last thing you want is surprise costs popping up during an HVAC install. A 7.5 ton packaged air conditioner and gas furnace, like the Daikin Light Commercial 7.5 Ton Packaged AC/Gas Furnace (Model DFG0904DM00001S), is a serious piece of equipment. It can keep 3,500–6,000 square feet comfortable year-round — but installing one isn’t as simple as dropping a box and flipping a switch.

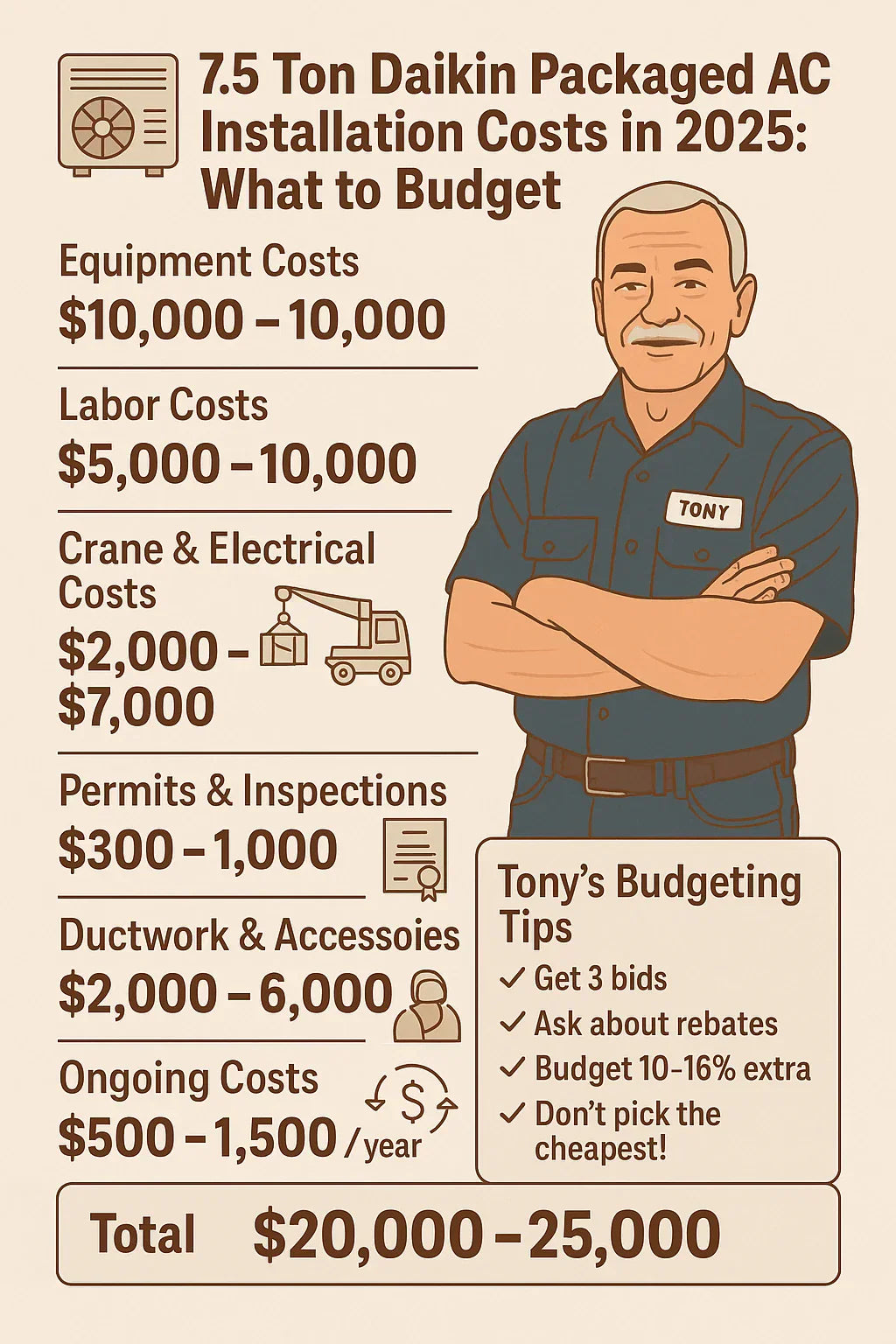

In 2025, you’re looking at $15,000–$25,000 installed for most projects. Let’s break down where that money goes — so you can budget smart, avoid hidden surprises, and keep your business on track.

💲 Equipment Costs in 2025

First, the system itself.

-

Daikin 7.5 Ton Packaged AC/Gas Furnace: $10,000–$15,000

-

Price depends on distributor, features, efficiency upgrades, and any accessories (economizers, curbs, advanced controls).

👉 This covers the unit only, before you even think about installation.

📌 According to HVAC installation cost data, commercial-grade packaged units are significantly more expensive than residential systems due to capacity and complexity.

🛠️ Labor Costs: The Big Variable

Labor is where costs swing the most.

-

Commercial HVAC contractor rates in 2025: $75–$125 per hour per technician.

-

Typical crew size: 2–4 techs + sometimes an electrician and sheet metal worker.

-

Install duration: 2–3 full days for most light commercial packaged systems.

That adds up to:

-

$5,000–$10,000 for labor.

Why so much? You’re not just bolting a system in place. Crews have to:

-

Remove the old unit

-

Set the new packaged system (often with a crane)

-

Connect gas, electric, and ductwork

-

Seal everything properly to meet code

📌 ACCA (Air Conditioning Contractors of America) stresses that quality installation can affect efficiency by up to 30%. Cheap labor often = higher long-term bills.

🏗️ Crane Lifts & Specialized Equipment

If you’re installing this Daikin unit on a rooftop (very common for light commercial setups), you’ll likely need a crane.

-

Crane rental: $500–$2,000 depending on location and access.

-

Permits for road closure or lift: $200–$500 in many cities.

👉 For ground-level installs, you may skip the crane — but still need a forklift or lift equipment.

📌 Trane Commercial HVAC notes rooftop packaged units are popular because they save indoor space, but installation is more complex.

⚡ Electrical & Gas Hookups

These systems aren’t plug-and-play. The Daikin model uses 460V, 3-phase power — standard for commercial but not always readily available.

-

Electrical panel upgrades: $1,500–$5,000 if your building’s panel can’t handle it.

-

Gas line adjustments: $500–$2,000 to size, run, or reconnect properly.

👉 If your building isn’t already set up for 3-phase power, costs rise quickly.

📌 Energy.gov emphasizes electrical compatibility as a hidden cost many buyers overlook.

📑 Permits & Inspections

Commercial installs always need permits.

-

Mechanical permits: $300–$800

-

Electrical permits: $200–$600

-

Gas line permits: $100–$300

-

Inspections: Usually included, but can add $200–$500

👉 Skipping permits is not an option — it risks fines, failed inspections, and insurance issues.

📌 International Code Council updates commercial mechanical codes that local inspectors enforce.

📦 Ductwork & Accessories

Most businesses already have ductwork, but tying in a new 7.5 ton system often requires adjustments.

-

Basic tie-in: $1,000–$3,000

-

Duct modifications/repairs: $2,000–$5,000

-

Economizer (for free cooling with outside air): $1,500–$3,000

-

Curb adapter for rooftop unit: $500–$1,500

-

Vibration isolators: $200–$500

👉 Don’t forget the thermostat. Smart commercial controls can run $500–$1,500.

📌 Carrier Commercial Controls show how advanced thermostats can cut costs further when paired with efficient systems.

🔁 Hidden & Ongoing Costs

Installing the system is just the start.

-

Maintenance contracts: $500–$1,500 per year

-

Filter replacements: $100–$300 annually

-

Coil cleaning & tune-ups: $200–$500 per visit

-

Belt/part replacements: $200–$1,000 as needed

👉 Over 10–15 years, maintenance can add $10,000+ — but it’s worth it. A neglected system runs hotter, breaks sooner, and wastes efficiency.

📌 Energy Star recommends annual maintenance to preserve efficiency ratings like IEER2.

📊 Real-World Budget Examples

Example 1: Ground-Level Retail Store (4,200 sq. ft.)

-

Equipment: $12,000

-

Labor: $6,000

-

Gas/Electrical tie-ins: $2,000

-

Permits: $600

-

Total: $20,600

Example 2: Rooftop Restaurant (3,800 sq. ft., crane needed)

-

Equipment: $13,000

-

Labor: $8,000

-

Crane + permits: $2,000

-

Ductwork mods: $3,000

-

Total: $26,000

Example 3: Medical Office (5,000 sq. ft., ground install with curb)

-

Equipment: $11,500

-

Labor: $5,500

-

Curb adapter + controls: $2,000

-

Maintenance contract year 1: $1,200

-

Total: $20,200

✅ Tony’s Budgeting Tips

-

Get 3 quotes from licensed contractors before signing.

-

Ask about rebates & tax credits. A 14.8 IEER2 system often qualifies for utility or ENERGY STAR incentives.

-

Budget 10–15% extra. Unexpected duct or electrical issues always pop up.

-

Don’t pick the cheapest installer. Bad installs kill efficiency and void warranties.

📌 Total Installed Cost Range (2025)

-

Ground install, minimal extras: $15,000–$18,000

-

Rooftop with crane & mods: $20,000–$25,000

👉 The sweet spot for most businesses will land around $18,000–$22,000.

📌 Final Word from Tony

Installing a 7.5 ton Daikin packaged unit isn’t just an equipment purchase — it’s a project. Between labor, permits, cranes, and ductwork, the install costs often match or exceed the unit price.

But if you budget smart — figure $18k–$22k all-in — you’ll get a system that delivers reliable comfort, solid efficiency, and peace of mind for the next 10–15 years.

Remember: don’t just buy the box — budget for the whole job. That’s how you avoid headaches and keep your business running smooth.

In the next topic we will know more about: Single-Stage vs. Two-Stage Packaged Systems: Which Is Best for Commercial Comfort?