👋 1️⃣ Meet the Job: A Classic 1970s Ranch That Needed a Smarter System

Every once in a while, a job comes along that reminds me why I love doing things the right way instead of the easy way.

This one was a single-story ranch home, built in the 1970s, sitting just outside of Franklin, Tennessee — about 1,400 square feet of well-loved family space. The owners, Mark and Denise, had called me in because their old air conditioner just couldn’t keep up anymore. It was a 3-ton R-410A system, barely eight years old, short-cycling itself into early retirement.

“It cools fine for 10 minutes, Mike — then it shuts off, and the humidity creeps right back in,” Denise told me.

When I stepped inside, I could already feel what was wrong. The air was cold — but sticky.

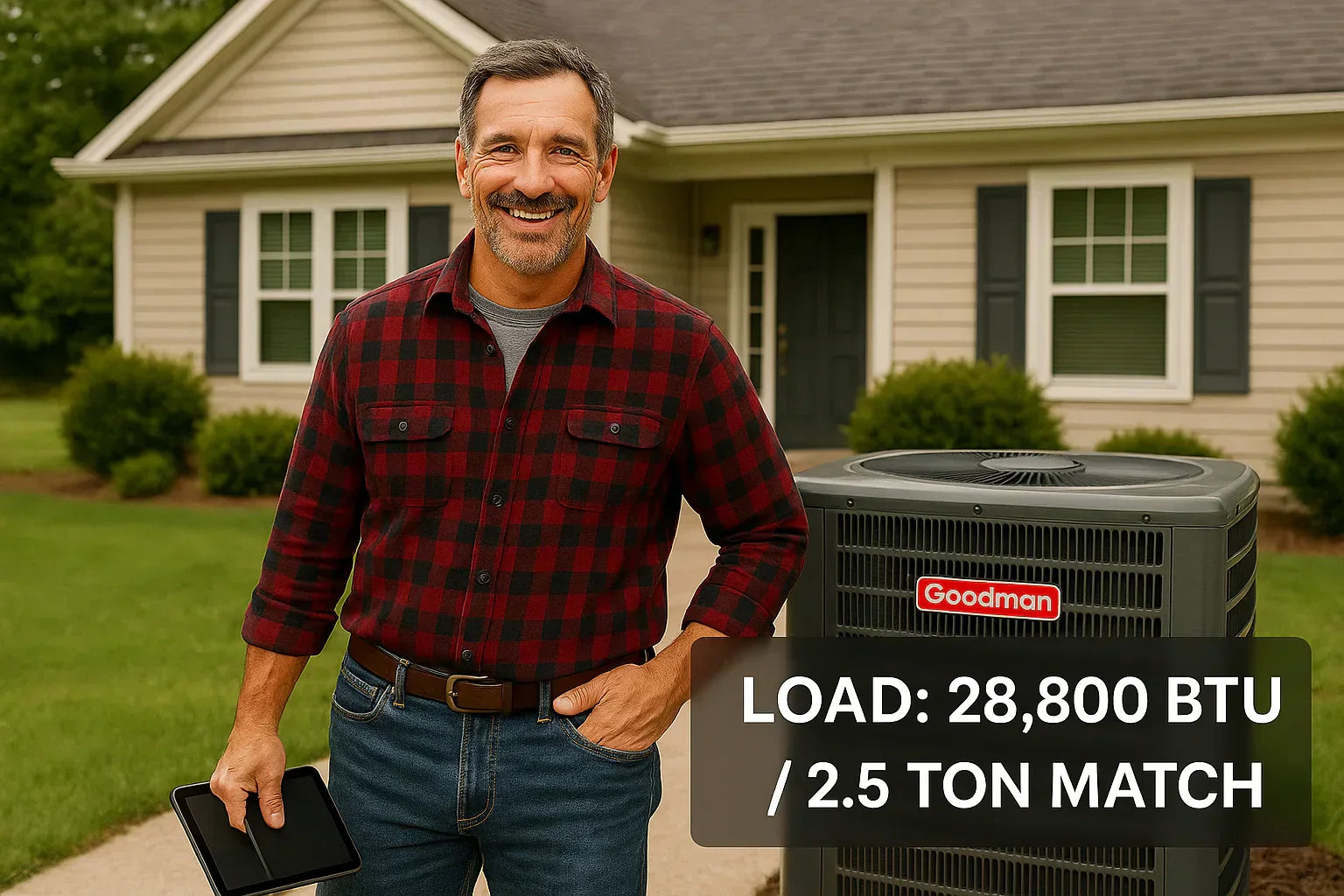

2.5 Ton Up To 15 SEER2 Goodman Air Conditioner Model

That’s a telltale sign of oversizing. The unit was too powerful for the space, cooling the air too quickly without running long enough to remove moisture. The result? A clammy, uncomfortable home and a system that was wearing itself out doing easy work the wrong way.

🧱 The House at a Glance

Before you ever touch a load calc, you have to know what you’re working with.

| Detail | Value |

|---|---|

| Floor area | 1,400 sq. ft. |

| Structure | Single-story ranch |

| Walls | 2×4 with R-13 batt insulation |

| Attic | R-30 blown insulation |

| Windows | Double-pane, south-facing front |

| Ductwork | Sheet metal trunk with flex branches in attic |

| Ceiling height | 8 ft |

| Location | Climate Zone 3A (Tennessee) |

On paper, a 3-ton might sound right for a 1,400 sq. ft. house using the old-school “500 sq. ft. per ton” rule.

But HVAC math isn’t one-size-fits-all.

That’s why I never guess — I calculate.

🧮 2️⃣ Step 1 — Manual J Load Calculation

Out came the tablet, and we ran a full Manual J load calculation.

Manual J is the foundation — the heat gain and loss math that tells you exactly how much conditioning a home needs. Every factor — walls, windows, doors, insulation, and even people — adds to or subtracts from the BTU total.

Here’s what this ranch told me:

| Parameter | Value |

|---|---|

| Floor area | 1,400 sq. ft. |

| Ceiling height | 8 ft |

| Design outdoor temp | 95°F |

| Indoor target temp | 75°F |

| Relative humidity goal | 50% |

| Infiltration | 0.4 ACH |

| Window-to-wall ratio | 12% |

| Attic insulation | R-30 |

| Ducts in attic | Yes (7% loss) |

🧠 Results

-

Sensible load: 23,600 BTU/hr

-

Latent load: 5,200 BTU/hr

-

Total load: 28,800 BTU/hr ≈ 2.4 tons

Right there, the story changed.

“This house didn’t need a 3-ton. It needed precision — not power.”

That extra half-ton was doing more harm than good. Oversized systems short-cycle, waste energy, and never remove humidity properly.

🔗 Reference: Energy Vanguard — What Is Manual J?

⚙️ 3️⃣ Step 2 — Manual S: Choosing the Right System

Once you know the load, Manual S is where you match that number to real-world equipment performance — not the label on the box.

This is where the Goodman 2.5-Ton 13.4 SEER2 R-32 Condenser came in.

I pulled up Goodman’s expanded performance tables.

At 95°F outdoor and 75°F indoor, this model (GLXS3B3010) delivers about 28,500 BTU of actual cooling.

Perfect match.

That’s not a coincidence — that’s the art of Manual S.

I paired it with a Goodman evaporator coil and a variable-speed blower furnace to make sure airflow and latent capacity stayed balanced.

“Good sizing isn’t about comfort today — it’s about performance for the next 15 years.”

🔗 Reference: Goodman — SEER2 Standards Overview

💨 4️⃣ Step 3 — Manual D: Duct Design & Airflow Check

No system is complete without airflow.

The previous installer had left a 12-inch return drop and a maze of 6-inch flex branches feeding six rooms. Static pressure at full fan speed was 0.68 inches of water column (w.c.) — too high for proper airflow.

I popped open the attic hatch and spent 20 minutes tracing every run.

Two branches were over 25 feet long. One was pinched behind a truss.

Here’s what we did:

| Fix | Result |

|---|---|

| Upsized return to 16" flex | Reduced static by 0.12" |

| Added a second return in hallway | Balanced airflow |

| Shortened two flex runs | Increased branch CFM |

| Installed balancing dampers | Evened out room temps |

Post-correction static: 0.47" w.c.

Target airflow: 400 CFM × 2.5 tons = 1,000 CFM delivered

“The ducts are the lungs of the system. You can’t breathe right through a straw.”

🔗 Reference: ACCA — Manual D Duct Design Guide

🌡️ 5️⃣ Step 4 — Why R-32 & SEER2 Were a Game-Changer

When I started swapping out R-410A systems for R-32 refrigerant models, the difference was immediate.

R-32 transfers heat faster, cools coils more efficiently, and does it all with about 25% less refrigerant charge.

It’s also future-ready — the EPA has already greenlit R-32 as the go-to low-GWP replacement.

Here’s what it meant for this job:

| Feature | R-410A (Old) | R-32 (New) |

|---|---|---|

| GWP | 2088 | 675 |

| Efficiency | Standard | +10–15% higher |

| Charge volume | Higher | 20–25% less |

| Cooling rate | Slower | Faster |

| Dehumidification | Average | Excellent |

“R-32 doesn’t just meet standards — it beats them. And paired with SEER2, it gives the homeowner measurable savings from day one.”

🔗 Reference: Daikin — R-32 Refrigerant Efficiency

🧰 6️⃣ Step 5 — Testing, Balancing, and Fine-Tuning

Once the Goodman was running, I pulled out the anemometer and thermometer.

| Room | CFM Goal | Measured | Adjustment |

|---|---|---|---|

| Living Room | 300 | 295 | ✔️ Perfect |

| Bedrooms (3) | 450 total | 440 | ✔️ Good |

| Kitchen/Dining | 250 | 260 | ✔️ Minor balance only |

Supply temps: 56–58°F

Return temps: 76°F

ΔT (temperature split): 20°F — ideal.

Humidity stabilized at 48%, even with Tennessee’s muggy July air.

“When you size, seal, and balance correctly, you don’t hear the system — you feel it.”

⚡ 7️⃣ Real Results: Comfort and Energy Savings

Before (3-Ton R-410A):

-

Short-cycling every 10–12 minutes

-

Indoor humidity 62–65%

-

Loud ducts, uneven rooms

-

July electric bill: $188

After (2.5-Ton R-32 SEER2):

-

Steady 25–30 min run times

-

Humidity balanced at 48%

-

Quiet airflow

-

July electric bill: $154

That’s a $34 monthly savings, not counting the reduced stress on components and quieter operation.

“When the system’s right, the thermostat becomes the most boring thing in your house.”

💡 8️⃣ Why Oversizing Fails Every Time

I always remind homeowners:

“Bigger doesn’t mean better. Bigger means worse — faster.”

Here’s why oversizing kills comfort:

-

Short cycles mean less dehumidification.

-

Rapid starts increase energy spikes.

-

Equipment wears out faster from constant on/off.

-

Uneven air distribution leads to hot and cold zones.

That’s why the 2.5-ton worked better than the old 3-ton. It ran longer, steadier, and hit the exact BTU target without overshooting.

🧠 9️⃣ Homeowner Experience: The True Test

Three weeks after the install, Denise called me back — not with a complaint, but a thank-you.

“Mike, the air just feels right. We don’t even touch the thermostat anymore.”

That’s what true comfort sounds like — silence. No cycling, no hot rooms, no sweating through your sheets. Just consistent, invisible performance.

I asked her to check the humidity with a small hygrometer:

48%. Perfect.

“Comfort isn’t magic. It’s math that feels like magic.”

🏠 🔟 Cost Breakdown (and Why It Paid Off)

| Item | Old 3-Ton System | New 2.5-Ton R-32 SEER2 |

|---|---|---|

| Equipment Cost | $4,300 | $4,600 |

| Installation | $1,200 | $1,400 (includes duct fixes) |

| Total | $5,500 | $6,000 |

| Est. Monthly Savings | — | $34 |

| Est. Payback Period | — | ~2.5 years |

After that, it’s all profit — in comfort and lower bills.

“Right-sizing always pays for itself. It’s one of the few times less really is more.”

🧮 11️⃣ Data Recap: The Final Numbers

| Metric | Before | After |

|---|---|---|

| System Type | 3.0-Ton R-410A | 2.5-Ton R-32 SEER2 |

| SEER Rating | 13.0 | 13.4 SEER2 (≈ 14.5 SEER old scale) |

| Total BTU | 36,000 | 28,800 (matched load) |

| Humidity | 62% | 48% |

| Static Pressure | 0.68" | 0.47" |

| Runtime | 12 min cycles | 28 min cycles |

| Comfort Score (Homeowner) | 6/10 | 10/10 |

🧩 12️⃣ Key Lessons from the Field

-

Manual J never lies. Guesswork always costs comfort.

-

Manual S keeps the math honest. Match real performance data, not nameplates.

-

Manual D makes or breaks the delivery. You can’t fix airflow after drywall.

-

R-32 and SEER2 efficiency are game-changers. Smaller systems now outperform the old giants.

-

Right-sizing saves energy and sanity. Comfort isn’t about brute force — it’s balance.

“The best systems aren’t seen or heard. They just work — perfectly.”

💬 13️⃣ Mike’s Takeaway

After 25 years in HVAC, I’ve learned that sizing is half art, half science.

But the difference between a good system and a great one always comes down to one thing: the numbers.

When you do it by the book — Manual J, S, and D — you’re not guessing. You’re guaranteeing comfort.

And this 1,400 sq. ft. ranch?

It’s proof that the math works — every single time.

🔗 14️⃣ Internal Link Strategy

| Link Type | Target Post | Purpose |

|---|---|---|

| Pillar | System Sizing 101 — How Mike Sanders Right-Sizes Every HVAC Job | Core foundation |

| Cluster | Manual J, S & D — The Alphabet Soup That Makes or Breaks Comfort | Technical depth |

| Cluster | Ductwork Efficiency — The Hidden Variable in System Sizing | Airflow tie-in |

| Cluster | How R-32 Systems Changed the Sizing Game in 2025 | Efficiency connection |

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: Smart Thermostats and Sizing — Why Control Logic Can Compensate for Small Gaps