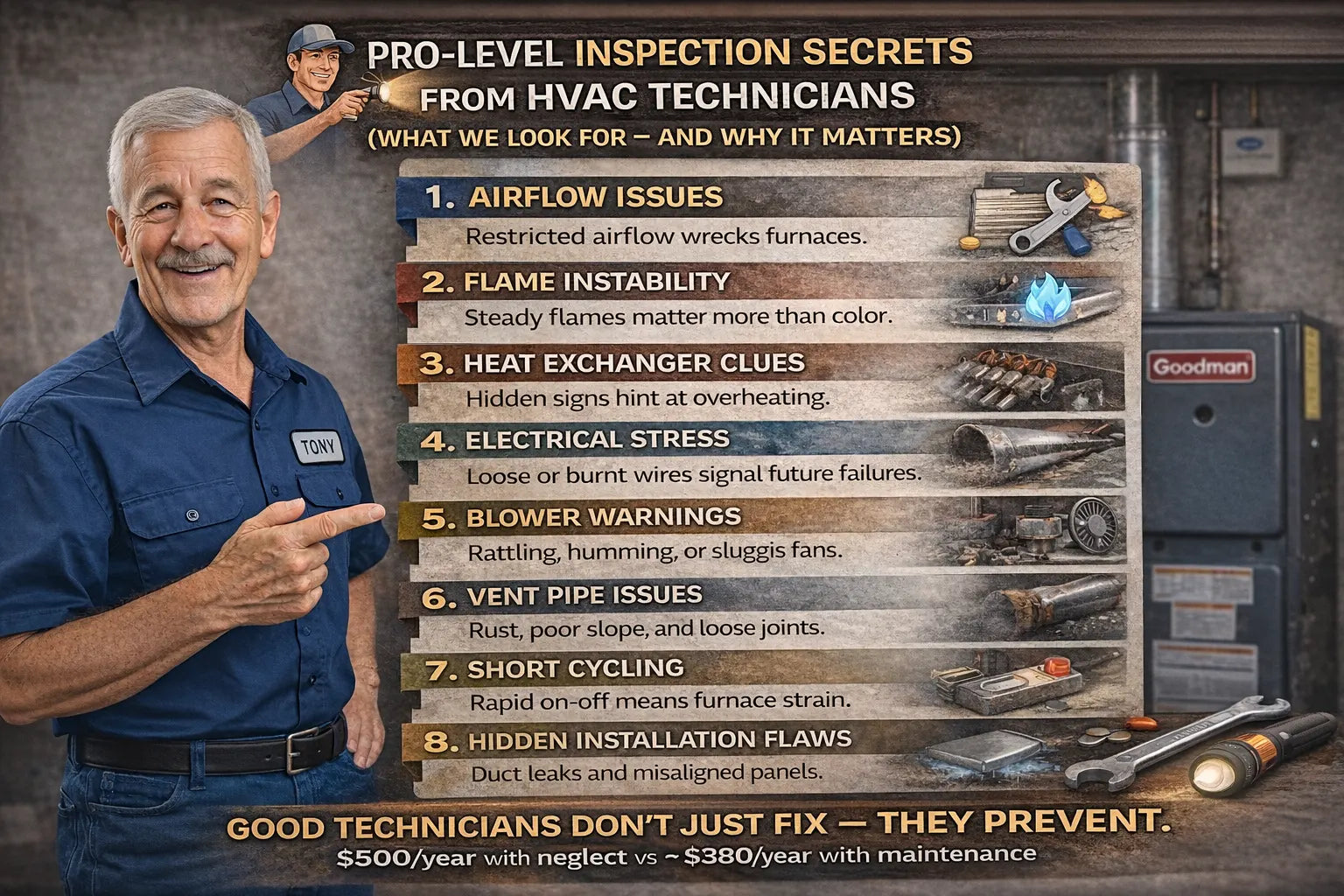

(What We Look For — and Why It Matters)

Most homeowners think a furnace inspection is just a guy showing up, changing a filter, and saying,

“You’re good for another year.”

That’s not a real inspection.

A professional HVAC inspection is about spotting problems before they become failures — using experience, patterns, and details most people never notice.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

I’ve inspected thousands of furnaces over the years. The good techs all look for the same warning signs, even if they don’t talk about them out loud.

Today, I’m pulling back the curtain.

🔍 The Technician Mindset: We Don’t Look for What’s Broken

Here’s the first secret:

Good technicians don’t look for failures — they look for trends.

We ask:

-

What’s working harder than it should?

-

What’s running hotter than normal?

-

What’s aging faster than expected?

Those answers tell us where a furnace is headed, not just where it is today.

🌬️ Secret #1: Airflow Tells Us Almost Everything

Before we touch tools, we evaluate airflow.

What Techs Check

-

Filter condition and filter type

-

Return air restriction

-

Supply airflow consistency

-

Blower sound and ramp-up behavior

Why It Matters

Restricted airflow causes:

-

Overheating

-

Short cycling

-

Premature heat exchanger damage

A furnace with airflow issues may still heat your home — but it’s burning through its lifespan.

https://www.energy.gov/energysaver/furnaces-and-boilers

🔥 Secret #2: Flame Shape Matters More Than Flame Color

Most homeowners hear:

“The flame should be blue.”

That’s only half the story.

What Techs Actually Watch

-

Flame stability (steady vs dancing)

-

Flame carryover between burners

-

Flame lift-off during startup

-

Delayed ignition

These signs tell us:

-

Burner alignment issues

-

Dirty or restricted ports

-

Improper combustion air

Even “blue” flames can signal problems if they behave incorrectly.

🧯 Secret #3: Heat Exchanger Clues Hide in Plain Sight

Cracked heat exchangers don’t announce themselves loudly.

What We Look For

-

Repeated limit switch trips

-

Discolored metal near the burner box

-

Unusual expansion noises

-

Signs of chronic overheating

Most exchanger failures are secondary damage caused by airflow neglect — not material defects.

🔗 https://www.nachi.org/gallery/heating/heat-exchanger-heat-flow

⚡ Secret #4: Electrical Issues Fail Slowly, Not Suddenly

Homeowners expect electrical failures to be instant.

Technicians know better.

What We Inspect

-

Wire insulation brittleness

-

Heat discoloration on terminals

-

Loose spade connectors

-

Control board mounting stress

Why It Matters

Loose or heat-stressed connections cause:

-

Intermittent shutdowns

-

Random lockouts

-

Misdiagnosed “bad boards”

Catching this early saves hundreds in unnecessary parts.

🔗 https://www.familyhandyman.com/article/what-is-a-furnace-tune-up/

🌪️ Secret #5: Blower Motors Give Warnings Long Before They Die

A blower motor rarely fails without warning.

What Techs Notice

-

Delayed startup

-

Humming before movement

-

Irregular airflow sounds

-

Excessive cabinet vibration

These point to:

-

Bearing wear

-

Dust-loaded blower wheels

-

Electrical strain

Ignoring these signs almost always leads to an expensive motor replacement later.

🌫️ Secret #6: Venting Problems Don’t Always Trip Alarms

This is a big one — especially on 80% AFUE furnaces.

What Techs Check

-

Vent slope consistency

-

Rust flaking inside joints

-

Loose or separated connections

-

Outdoor termination clearance

Poor venting can:

-

Reduce efficiency

-

Increase run time

-

Stress safety switches

-

Create carbon monoxide risks

🔗 https://www.cdc.gov/carbon-monoxide/about/index.html

🧠 Secret #7: Short Cycling Is a Silent Furnace Killer

If a furnace turns on and off too often, we pay attention.

What Short Cycling Tells Us

-

Oversized equipment

-

Thermostat issues

-

Airflow restriction

-

Control logic problems

Why Techs Care

Every cycle stresses:

-

Igniters

-

Gas valves

-

Blower motors

Reducing unnecessary cycles can add years to a furnace’s life.

🧰 Secret #8: We Check What Homeowners Never Think To

Some of the most important inspection points aren’t obvious.

Examples

-

Furnace cabinet alignment

-

Panel seal integrity

-

Duct leakage near the furnace

-

Combustion air availability

Small installation issues can create long-term maintenance problems.

🚨 Secret #9: Safety Switches Are Diagnostic Tools, Not Enemies

When a safety switch trips, homeowners get frustrated.

Technicians get curious.

What We Ask

-

Which switch tripped?

-

How often?

-

Under what conditions?

Safety devices don’t fail randomly.

They trip because something else is wrong.

📊 Secret #10: We Think in Lifespan, Not Repairs

Homeowners ask:

“What’s wrong with it today?”

Technicians ask:

“What will fail next if this continues?”

That’s the difference between:

-

Fixing symptoms

-

Preventing failure

A pro inspection is about trajectory, not just status.

🧠 Why These Secrets Matter to Homeowners

When you understand what techs look for, you can:

-

Ask better questions

-

Recognize good service

-

Avoid unnecessary repairs

-

Catch issues early

And most importantly — you stop thinking maintenance is “optional.”

🏁 Final Word from Tony

Here’s the honest truth:

The best furnace inspections don’t result in repairs — they prevent them.

Pro-level technicians aren’t magicians.

They’re just trained to notice patterns, stress, and early warnings.

When your furnace gets inspected the right way, it doesn’t just run —

it lasts.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Troubleshooting Common Issues of Goodman GR9S800803BN Before Calling a Pro