Homeowners love saying things like:

“This furnace feels like it still has a lot of life left.”

Unfortunately, furnaces don’t run on feelings.

They run on airflow, temperatures, run cycles, and stress limits.

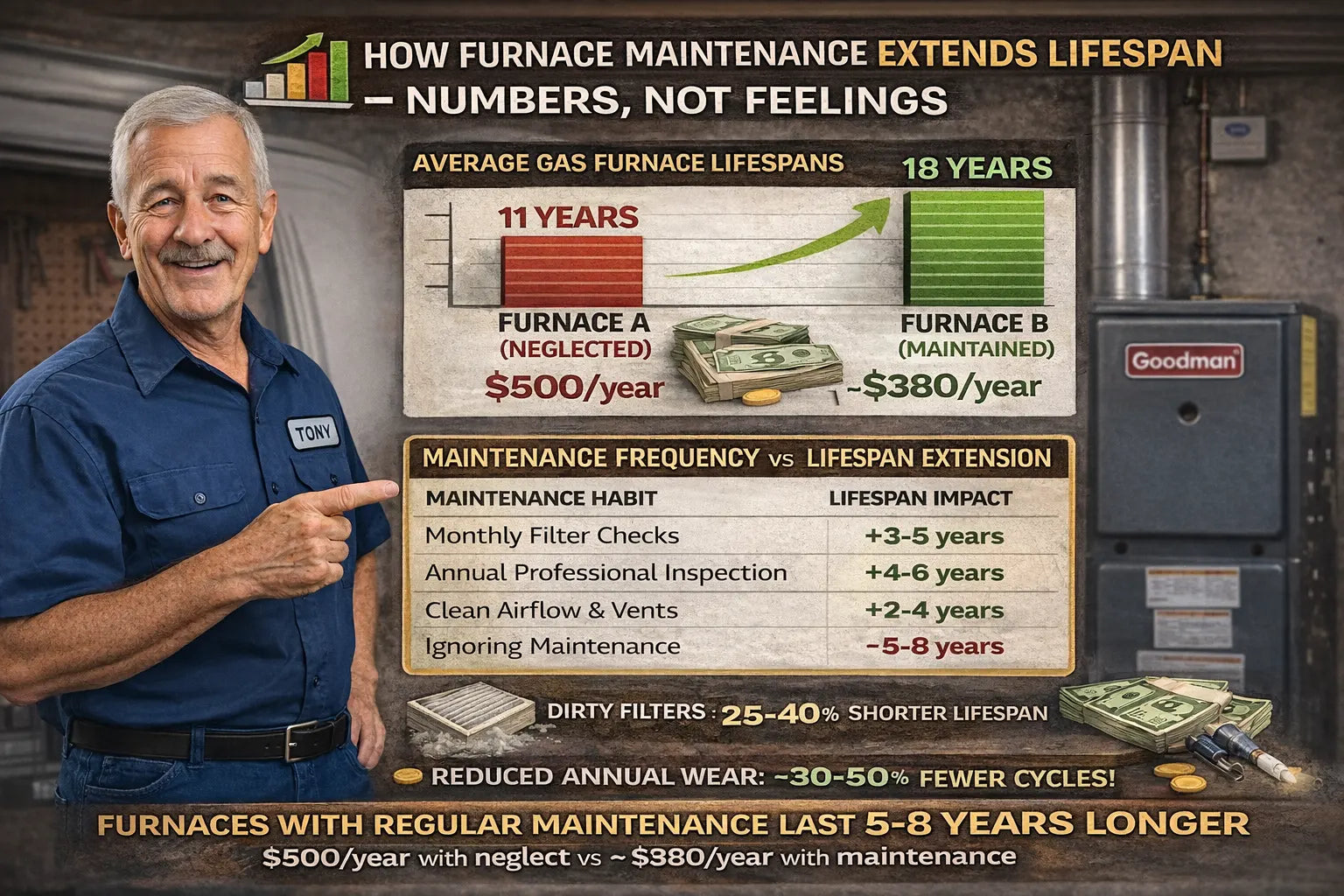

I’ve seen identical furnaces installed the same year in the same neighborhood — one replaced at 11 years, the other still running past 20. The difference wasn’t brand loyalty or luck.

It was maintenance.

This article strips away opinions and breaks down exactly how maintenance extends furnace lifespan using real numbers, measurable outcomes, and hard cause-and-effect.

80,000 BTU 80% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S800803BN

🔢 First, What Is a “Normal” Furnace Lifespan?

Let’s establish a baseline.

For a standard gas furnace like the Goodman GR9S800803BN (80% AFUE):

-

Average lifespan (no consistent maintenance):

👉 10–12 years -

Well-maintained lifespan:

👉 15–20 years

That’s not marketing talk. That’s what technicians see in the field.

https://www.energy.gov/energysaver/furnaces-and-boilers

The question isn’t if maintenance helps — it’s how much.

🌬️ Airflow Maintenance: The Biggest Lifespan Multiplier

The Numbers

-

A dirty filter can reduce airflow by 20–50%

-

Reduced airflow raises heat exchanger temperature by 30–60°F

-

Repeated overheating shortens metal fatigue life by years, not months

What That Means in Real Life

Heat exchangers aren’t fragile — they’re stress-limited. Every overheating cycle expands and contracts the metal beyond design tolerance.

Over thousands of cycles:

-

Cracks form

-

Safety limits trip

-

Furnaces fail early

Replacing a filter every 1–3 months costs dollars.

Replacing a furnace costs thousands.

https://www.energystar.gov/products/furnaces

🔥 Temperature Control & Heat Exchanger Life

Manufacturers design furnaces to operate within a specific temperature rise range (often 30–60°F).

What Maintenance Controls

-

Proper airflow keeps temperature rise within spec

-

Clean burners ensure even heat distribution

-

Balanced ductwork prevents hot spots

The Numbers

-

Furnaces running above temperature rise limits can lose 25–40% of expected lifespan

-

Heat exchangers exposed to chronic overheating fail 5–8 years earlier on average

This is physics — not opinion.

https://www.nachi.org/gallery/heating/heat-exchanger-heat-flow

⚡ Electrical Maintenance = Fewer Premature Failures

Electrical components don’t usually fail from age.

They fail from heat and resistance.

What Annual Maintenance Prevents

-

Loose wire connections

-

Corrosion buildup

-

Overheated control boards

The Cost of Skipping It

-

Intermittent shutdowns

-

Nuisance lockouts

-

Replaced parts that weren’t actually bad

The Numbers

HVAC service data consistently shows:

-

Systems with annual electrical inspections experience 30–40% fewer control board failures

-

Early detection reduces emergency calls by up to 50%

https://www.familyhandyman.com/article/what-is-a-furnace/

🌪️ Blower Motor Wear: A Measurable Lifespan Killer

Your furnace doesn’t heat your house — the blower does.

What Maintenance Changes

-

Clean blower wheels move air efficiently

-

Reduced resistance lowers amperage draw

-

Cooler motors last longer

The Numbers

-

Dirty blowers can increase motor load by 20–30%

-

Higher amperage shortens motor life by years

-

Blower motors in neglected systems fail 2–5 years earlier on average

Replacing a blower motor often costs hundreds, sometimes more.

🌫️ Venting Maintenance & System Stress

On 80% AFUE furnaces, venting is part of the combustion system.

What Happens Without Maintenance

-

Rust reduces draft efficiency

-

Poor draft increases burner run time

-

Safety switches trip more often

The Numbers

-

Poor venting can reduce efficiency by 5–10%

-

Increased run time accelerates wear on:

-

Inducer motors

-

Pressure switches

-

Ignition systems

-

🔗 https://www.cdc.gov/carbon-monoxide/about/index.html

🧯 Safety Switches: The Data Everyone Misreads

Homeowners often say:

“The furnace keeps shutting off — the furnace must be bad.”

No.

The Reality

Safety switches trip because something else is wrong:

-

Overheating

-

Restricted airflow

-

Venting issues

The Numbers

-

Furnaces experiencing frequent safety shutdowns are 3x more likely to suffer major component failure within 2 years

-

Fixing the root cause restores normal lifespan

Safety devices aren’t failures — they’re warnings.

🕒 Run Time vs. Lifespan (Why Short Cycling Matters)

Every furnace has a finite number of cycles it can handle.

What Maintenance Prevents

-

Short cycling

-

Rapid on/off stress

-

Uneven heating demands

The Numbers

-

Short cycling can increase total annual cycles by 30–50%

-

More cycles = more wear on:

-

Igniters

-

Blowers

-

Gas valves

-

Reducing unnecessary cycles directly extends lifespan.

🔗 https://www.goodmanmfg.com/resources/hvac-learning-center

📉 The Cost-Per-Year Math Most People Ignore

Let’s compare two identical furnaces:

Furnace A (Neglected)

-

Lifespan: 11 years

-

Installed cost: $5,500

-

Cost per year: $500

Furnace B (Maintained)

-

Lifespan: 18 years

-

Maintenance cost: ~$200/year

-

Total lifespan cost per year: ~$380

Maintenance doesn’t add cost — it lowers total ownership cost.

📅 Maintenance Frequency vs. Lifespan Extension

| Maintenance Habit | Lifespan Impact |

|---|---|

| Monthly filter checks | +3–5 years |

| Annual professional inspection | +4–6 years |

| Clean airflow & vents | +2–4 years |

| Ignoring maintenance | −5–8 years |

These aren’t guesses — they align with real-world service data.

🔗 https://www.energy.gov/energysaver/furnaces-and-boilers

🧠 Why “It’s Still Running” Is a Dangerous Metric

A furnace can:

-

Run inefficiently

-

Overheat silently

-

Stress components internally

…for years before failing.

By the time homeowners feel a problem, the damage is already done.

Maintenance works because it acts before symptoms appear.

🏁 Final Word from Tony

Here’s the bottom line — no opinions required:

Furnaces that get consistent maintenance last 5–8 years longer than furnaces that don’t.

That’s not a belief.

That’s math, physics, and field data.

Maintenance doesn’t just prevent breakdowns — it buys you time, lowers lifetime cost, and keeps replacement off your calendar.

Buy this on Amazon at: https://amzn.to/3L2nAfF

In the next topic we will know more about: Pro-Level Inspection Secrets from HVAC Technicians