If startup is where a PTAC proves itself, pre-start is where you either set it up for success—or quietly sabotage it.

I’ve been called in plenty of times for “bad units” that turned out to be fine. The real problem? Someone skipped the basics before powering up. Missing tools, tight clearances, incorrect breakers—small oversights that turn into big headaches.

This guide walks through everything that must be in place before you ever apply power, using the Amana J-Series 15,000 BTU PTAC with 3.5 kW electric heat as our reference. Whether you’re a contractor, maintenance tech, or confident DIYer, this checklist keeps you out of trouble.

🧠 Why the Pre-Start Phase Matters More Than Startup

Startup gets all the attention, but pre-start is where most failures are born.

When a PTAC is powered without proper prep, you risk:

-

Immediate error codes

-

Nuisance breaker trips

-

Poor airflow and short cycling

-

Condensate leaks

-

Control board damage

-

Voided warranty claims

Doing pre-start right doesn’t take long—but skipping it costs time, money, and credibility.

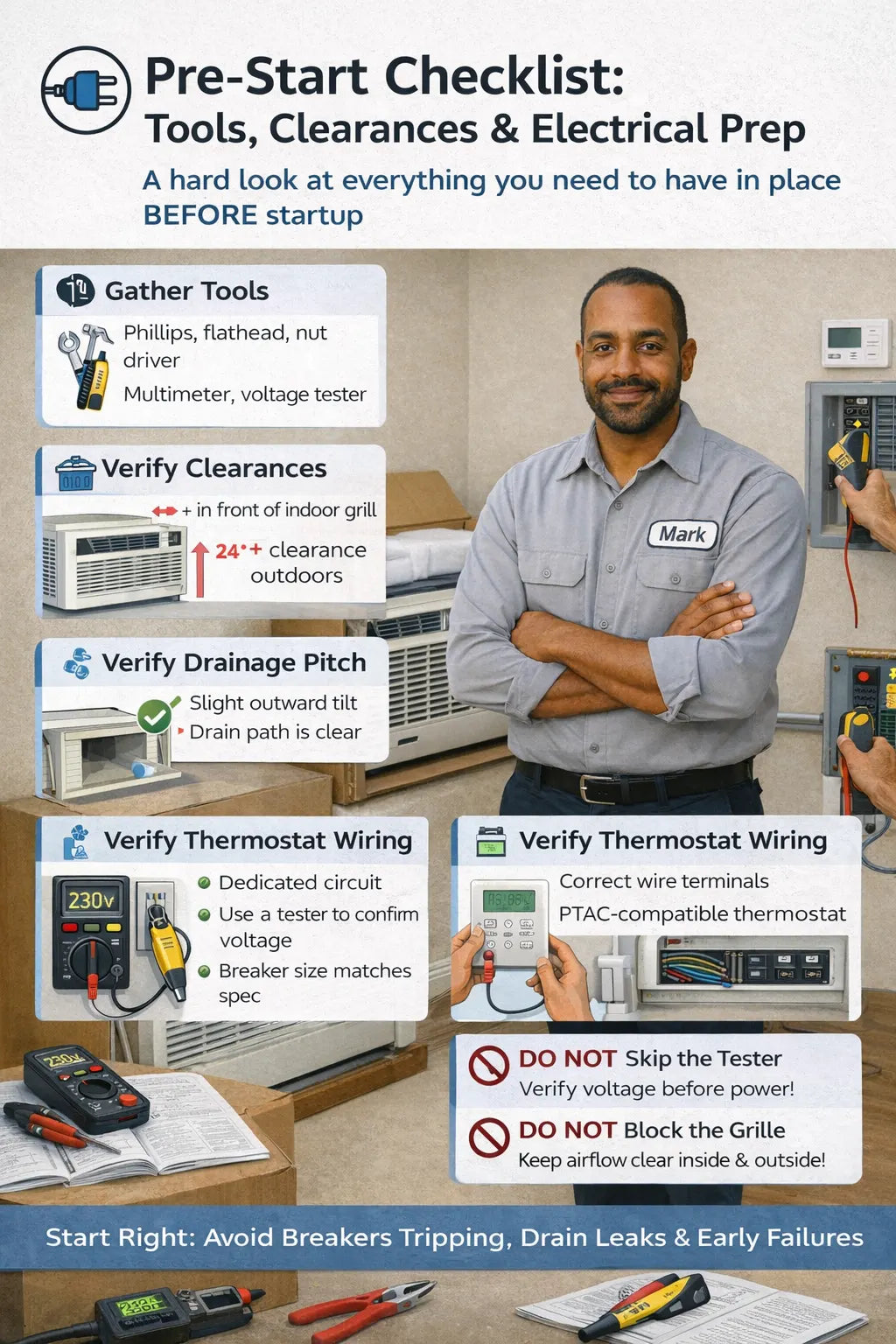

📦 Section 1: Tools You Actually Need (Not Just What’s Nearby)

You don’t need a truck full of gear, but you do need the right tools within reach before installation and startup.

🔧 Core tool checklist

-

Phillips and flathead screwdrivers

-

Nut driver or socket set

-

Level (short torpedo level works fine)

-

Flashlight or headlamp

-

Gloves (coil fins are sharp)

⚡ Electrical verification tools

-

Multimeter or voltage tester

-

Non-contact voltage detector (recommended)

These aren’t “nice to have.” If you can’t verify voltage or breaker size, you’re guessing—and guessing damages equipment.

🧱 Section 2: Wall Sleeve & Structural Readiness

The PTAC depends on the wall sleeve for support, airflow, and drainage. If the sleeve isn’t right, the unit never will be.

🧭 Sleeve alignment checklist

-

Level side-to-side

-

Slight outward pitch (for condensate drainage)

-

No warping, rust, or loose mounting screws

-

Interior of sleeve completely clear

Even a small inward tilt can cause water to drain into the room instead of outside.

🌬️ Outdoor grille check

-

Installed securely

-

No shipping blocks left in place

-

Clear of debris, plants, or screens

Restricted airflow at the grille equals poor performance and higher amp draw.

📏 Section 3: Clearance Requirements — Give the Unit Room to Breathe

PTACs move a lot of air. Crowding them is one of the fastest ways to create noise, overheating, and cycling issues.

🏠 Interior clearance basics

-

Front grille completely unobstructed

-

No furniture, curtains, or beds blocking airflow

-

Adequate space to remove the chassis later for service

🌳 Exterior clearance basics

-

No walls, fencing, or equipment directly blocking exhaust

-

Snow lines considered in cold climates

-

No dryer vents or exhaust fans blowing into the unit

Clearance issues don’t always show up on day one—but they shorten the unit’s lifespan.

⚡ Section 4: Electrical Prep — Where Most Mistakes Happen

Electrical prep is the most critical—and most commonly skipped—part of pre-start.

The Amana J-Series PTAC is typically configured for 208/230V, but never assume.

🔌 Electrical checklist

-

Dedicated circuit (no shared loads)

-

Correct voltage verified with a tester

-

Breaker size matches manufacturer specs

-

Outlet or hard-wire connection in good condition

Manufacturer reference:

Amana PTAC Technical & Electrical Resources

If voltage is wrong or unstable, do not power the unit “just to see if it works.” That’s how control boards get fried.

🔍 Section 5: Power Connection Type — Cord vs. Hard-Wire

Before startup, confirm how the unit is designed to receive power.

🔌 Power cord setups

-

Correct Amana-approved cord

-

Secure plug fit

-

No heat damage at the receptacle

🧲 Hard-wired setups

-

Proper strain relief installed

-

Ground connected securely

-

No exposed copper or loose lugs

Loose or undersized connections cause heat buildup—and heat kills electronics.

🧠 Section 6: Controls & Thermostat Prep

A surprising number of startup calls come down to control configuration, not mechanical failure.

🎛️ Control options to confirm

-

On-board controls enabled (if used)

-

Wall thermostat compatibility verified

-

Correct wiring terminals used

If using a wall thermostat:

-

Confirm it’s PTAC-compatible

-

Double-check wiring against the diagram

-

Secure thermostat placement away from drafts

Control issues often show up as:

-

No response at startup

-

Incorrect temperature readings

-

Short cycling or lockouts

💧 Section 7: Condensate Drainage Readiness

Cooling mode creates water. If the unit can’t drain properly, you’ll know fast.

🚿 Drainage pre-check

-

Sleeve pitched outward

-

Drain openings clear

-

No sealant blocking drain paths

Condensate problems don’t just cause messes—they can damage floors, walls, and guest satisfaction in commercial spaces.

For best practices, see:

Energy.gov – HVAC Drainage & Moisture Control

🔎 Section 8: Final Walk-Around Before Power

Before you flip the breaker, do one last slow check.

✅ Final pre-start checklist

-

Unit fully seated in sleeve

-

Mounting screws installed

-

Tools removed from unit area

-

Manuals accessible

-

Breaker off before initial connection

This is the moment where patience pays off.

⚠️ Section 9: What Not to Do Before Startup

Some mistakes come up again and again.

🚫 Avoid these pre-start errors

-

Powering up before verifying voltage

-

Forcing the unit into a misaligned sleeve

-

Blocking airflow “temporarily”

-

Ignoring small wiring inconsistencies

-

Skipping the level check

None of these save time. All of them create callbacks.

🧠 Mark’s Final Take

Startup problems almost never start at startup.

They start when someone:

-

Assumes instead of verifies

-

Rushes instead of prepares

-

Skips instead of checks

If you take the time to handle tools, clearances, and electrical prep properly, startup becomes boring—and boring is exactly what you want. A quiet, uneventful first power-up means the system is ready to do its job.

Get pre-start right, and everything after that gets easier.