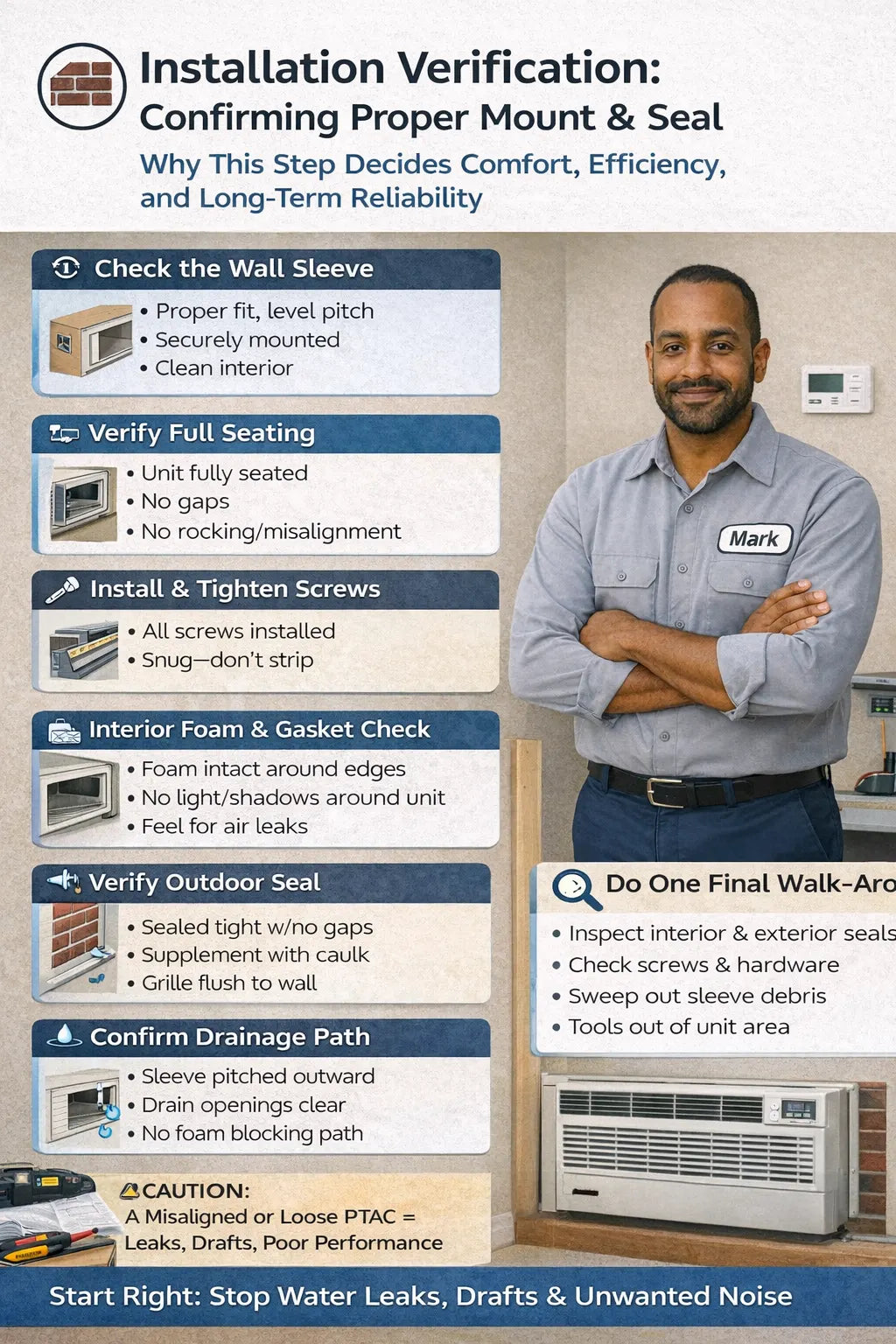

Why This Step Decides Comfort, Efficiency, and Long-Term Reliability

If there’s one step installers and DIYers underestimate, it’s installation verification.

I’ve seen PTAC units that were wired perfectly, powered correctly, and configured properly—yet still leaked water, short-cycled, or rattled like crazy. When you peel it back, the cause is almost always the same: the unit wasn’t mounted or sealed correctly.

This guide focuses on verifying that your PTAC—using the Amana J-Series 15,000 BTU PTAC with 3.5 kW electric heat as our reference—is physically installed the way it’s supposed to be before you ever judge performance.

Because once the unit is sealed into the wall, mistakes get expensive.

🧠 Why Mount & Seal Verification Matters More Than You Think

A PTAC doesn’t just cool or heat—it also:

-

Manages condensate

-

Moves large volumes of air

-

Isolates indoor and outdoor environments

-

Handles vibration and thermal expansion

If mounting or sealing is off, you’ll see:

-

Indoor water leaks

-

Outside air infiltration

-

Reduced efficiency

-

Premature component wear

And no thermostat setting fixes any of that.

📦 Step 1: Confirm the Correct Wall Sleeve Is Installed

Before checking the unit itself, verify the foundation.

🧱 Wall sleeve verification checklist

-

Sleeve is manufacturer-approved or compatible

-

Sleeve is fully secured to the wall framing

-

No visible warping or damage

-

Interior of sleeve is clean and unobstructed

A loose or distorted sleeve guarantees sealing problems later.

📐 Step 2: Level Check — The Silent Deal-Breaker

This is one of the most skipped steps—and one of the most important.

🧭 What “level” actually means

-

Side-to-side: perfectly level

-

Front-to-back: slightly pitched outward (toward exterior)

That outward pitch allows condensate to drain outside instead of into the room.

🚿 What happens if this is wrong

-

Water pools inside the chassis

-

Drain ports don’t work as intended

-

Indoor leaks show up weeks later

Always verify with a level—never eyeball it.

🚪 Step 3: Confirm Full Seating of the PTAC Chassis

The PTAC chassis must sit fully and evenly inside the sleeve.

✅ Proper seating indicators

-

Unit slides in smoothly without force

-

Chassis contacts sleeve stops

-

No visible gaps around the perimeter

-

Unit does not rock or shift when pressed

If the unit binds or stops short, do not force it. Forcing a PTAC can damage:

-

Electrical wiring

-

Cabinet alignment

Back it out and find the obstruction.

🪛 Step 4: Mounting Hardware — Small Screws, Big Impact

Once seated, the unit must be secured.

🔩 Mounting verification

-

All required mounting screws installed

-

Screws tightened evenly (not overtightened)

-

No stripped holes

-

Unit remains square after fastening

Loose mounting leads to vibration noise, while overtightening can warp the chassis.

🌬️ Step 5: Interior Air Seal Verification

This is where comfort and efficiency live or die.

🏠 Interior sealing checkpoints

-

Foam gaskets intact and uncompressed

-

No visible daylight around unit edges

-

No air movement felt around the perimeter during operation

-

Trim or escutcheon installed properly (if applicable)

Air leaks allow:

-

Hot or cold outdoor air intrusion

-

Humidity issues

-

Temperature instability

-

Higher energy use

A PTAC should feel like part of the wall—not a draft source.

🌧️ Step 6: Exterior Weather Seal Verification

What happens outside matters just as much.

🌳 Exterior seal checklist

-

Outdoor grille installed correctly

-

No gaps between sleeve and exterior wall

-

Sealant intact (no cracks or missing sections)

-

No direct exposure to runoff from gutters or roofs

Improper exterior sealing leads to moisture infiltration, freeze damage, and corrosion.

For building envelope best practices, see:

Energy.gov – Air Sealing & Moisture Control

💧 Step 7: Drainage Path Confirmation

Drainage is mechanical, not magical.

🚿 Verify drainage by checking:

-

Sleeve pitch (again—this matters)

-

Drain openings are clear

-

No sealant blocking drain paths

-

No insulation stuffed into drain areas

If possible, pour a small amount of water into the drain pan area and confirm it exits outdoors.

🔊 Step 8: Noise & Vibration Test Before Power-Up

Even before startup, you can catch problems.

🎧 Physical test

-

Gently press on the unit—no rattling

-

Shake test—no loose components

-

Confirm no metal-to-metal contact inside sleeve

Noise complaints almost always trace back to mounting issues, not bad motors.

🔍 Step 9: Final Visual Walk-Around

Before moving on to startup, do one slow inspection.

✅ Final verification checklist

-

Unit square in the opening

-

All fasteners installed

-

Seals intact inside and out

-

Drainage path clear

-

No tools or packaging left behind

If something feels rushed, it probably was.

⚠️ Common Installation Verification Mistakes

I see these over and over:

🚫 Avoid these errors

-

Assuming the sleeve pitch is “close enough”

-

Skipping foam gasket replacement

-

Over-sealing and blocking drains

-

Ignoring small gaps because “trim will cover it”

-

Blaming the unit for airflow noise caused by misalignment

Most PTAC “defects” are installation defects.

🧠 Mark’s Final Take

A PTAC can only perform as well as it’s installed.

You can have perfect electrical prep and a flawless startup sequence—but if the unit isn’t mounted solidly and sealed correctly, you’ll fight comfort, efficiency, and reliability for the rest of its life.

Installation verification isn’t glamorous.

But it’s the difference between a quiet, efficient system—and a constant service call.

Do this step right, and everything after it gets easier.