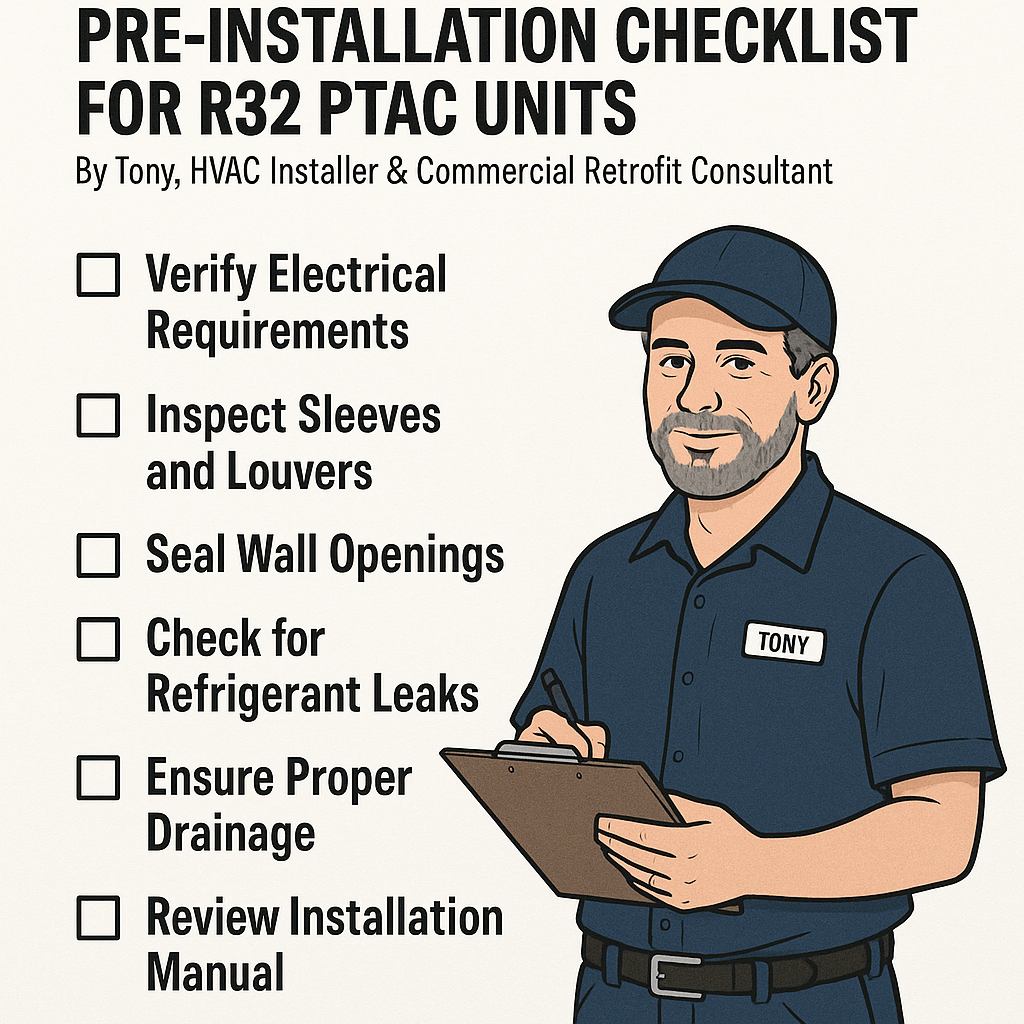

Why This Checklist Matters

I can’t tell you how many installs I’ve seen go sideways because someone skipped the basics. When it comes to R32 PTAC units, getting your pre-installation game tight is the difference between a clean job and a callback.

Whether you're retrofitting a hotel, upgrading a senior living community, or outfitting new student housing — this is the checklist I use before every R32 install.

Print it, save it, tape it to your toolbox.

🔌 1. Electrical & Power Supply

✔️ Confirm voltage matches unit (typically 208/230V for PTACs)

✔️ Dedicated circuit with correct amperage breaker installed

✔️ Check for NEMA plug compatibility or hardwire-ready terminal block

✔️ Ground wire in place and sized per NEC

✔️ Test outlet or disconnect box with voltage meter — no drops or spikes

⚡ Tony’s Tip: Don’t assume power is ready just because there’s a box. I always test the load side myself.

🧱 2. Wall Sleeve Prep

✔️ Existing sleeve is level, clean, rust-free, and free of debris

✔️ Sleeve dimensions match new R32 PTAC unit size

✔️ Proper drainage slope (⅛” forward tilt to exterior)

✔️ Back grille in place — clean and unblocked

✔️ Inspect foam seals or order new gasket kit if worn

🧰 Not using a sleeve? You’ll need one — it’s required for structural support and airflow routing.

🌬️ 3. Airflow Clearance

✔️ 36” clear space in front of unit indoors

✔️ 24” clear behind outdoor grille (no shrubs, bricks, or dumpsters)

✔️ No curtains, headboards, or furniture blocking indoor intake/output

✔️ Ductless return airflow only — don’t rig into central ducting

💨 PTACs breathe better with space. Poor airflow = poor performance.

🧪 4. Site Safety & Environment

✔️ Work area clear of flammable vapors or ignition sources

✔️ Confirm unit is R32-rated (A2L compatible), not an older R410A mismatch

✔️ Leak detection tools on-site and functioning

✔️ Technicians are EPA 608 certified and trained on A2L refrigerants

✔️ Fire extinguisher available (just good practice)

🔍 R32 is safe, but treat every install like someone’s living there — because they are.

🏗️ 5. Mounting & Structural Readiness

✔️ Wall condition stable (no crumbling brick, rot, or termite damage)

✔️ Reinforcement in place for sleeve weight, if needed

✔️ Bracing for heavy-duty sub-base (if using one)

✔️ Sealant, insulation, or weather stripping on hand

✔️ Correct fasteners rated for wall type (masonry, metal stud, wood, etc.)

🏠 Tony’s Rule: If you wouldn’t trust the wall to hold your toolbox, don’t put a 120-lb unit in it.

📦 6. Equipment & Documentation

✔️ R32 PTAC unit received, inspected, and undamaged

✔️ Serial number documented for warranty

✔️ Install manual printed or downloaded

✔️ Owner's manual ready for hand-off

✔️ Labeling correct: refrigerant type, flammability warning, GWP rating

📎 Some models ship with transit brackets or internal stabilizers — remove before startup.

🧾 Final Checklist Summary

| Category | Status ✅/❌ |

|---|---|

| Electrical/Power | |

| Wall Sleeve | |

| Airflow Clearance | |

| Safety & Environment | |

| Structural Readiness | |

| Equipment/Documents |

💬 I leave a printed copy with the building manager, especially in hotels or properties with maintenance staff — makes you look sharp and keeps everyone on the same page.

Ready to Install?

If you’ve checked all the boxes, you’re ready to move on to the install. And if you haven’t — now’s the time to fix it. You’ll thank yourself later.

Need a dependable R32 PTAC with sealed components, install-ready accessories, and clear manuals? Check out the lineup at The Furnace Outlet.