Maintenance Guide: How to Keep Your R-32 PTAC Running Smooth for 15+ Years

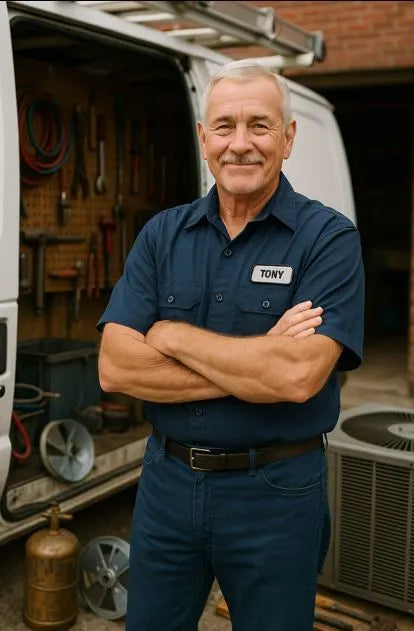

🧰 Tony’s Intro: Most PTACs Die of Neglect, Not Old Age

You wouldn’t drive your truck for 100,000 miles without changing the oil — but every week I walk into hotels and apartments where the PTAC filters look like dryer lint blankets. Folks think because PTACs are sealed units, they can just plug ’em in and forget ’em.

That’s why so many units burn out early. The truth? A well-maintained PTAC can easily last 15 years, sometimes longer. Most of the “bad” units I replace are victims of dirty coils, clogged drains, or lazy maintenance schedules — not factory defects.

And with today’s R-32 refrigerant models, the stakes are even higher. They run cooler, use less charge, and rely on precision airflow. Block that airflow or let water back up, and you’ll kill your efficiency and compressor life fast.

So this guide covers everything I’ve learned in 25 years of servicing PTACs — monthly habits, seasonal deep-cleans, electrical inspections, drain management, and the field tricks that actually make a difference.

🧼 1. Monthly Filter Maintenance

Why It Matters

Air filters are the PTAC’s first defense. Clogged filters restrict airflow, making the fan motor work harder and reducing efficiency by up to 15 percent (Energy.gov maintenance guide).

What To Do

-

Remove the front grille.

-

Slide out the mesh filter.

-

Vacuum off dust or rinse it under lukewarm water.

-

Let it dry completely before reinstalling.

If the filter’s torn or warped, replace it — they cost less than $10 each.

👉 Tony’s Tip: In hotels or apartments with smokers or pets, double the cleaning frequency. Odor-coated filters kill airflow faster than dust ever will.

💨 2. Coil Cleaning: The Heart of Efficiency

The evaporator and condenser coils move the heat. Dirty coils trap moisture and reduce heat transfer.

Tools You Need

-

Soft brush

-

Coil cleaner (non-acidic, foaming type)

-

Fin comb for bent aluminum

(Energy Star PTAC maintenance guide)

Step-by-Step

-

Kill the power.

-

Remove the front grille and access panel.

-

Spray coil cleaner evenly.

-

Let the foam expand and rinse with low-pressure water.

-

Straighten fins if bent.

👉 Tony’s Rule: Never use a pressure washer — I’ve seen more coils destroyed that way than cleaned. Gentle water and patience win.

💧 3. Condensate Drain & Pan Care

R-32 systems produce more condensate because of cooler coil temps. If that water can’t exit, it backs up into the wall sleeve.

Every 3 Months

-

Flush the drain pan with a vinegar-and-water mix.

-

Check the sleeve’s slope (¼ inch downward toward the outside).

-

Inspect the drain hose or port for algae.

(EPA household moisture prevention)

👉 Tony’s Trick: Install a $3 condensate tablet in each drain pan every spring — it prevents slime buildup all season.

⚡ 4. Electrical & Thermostat Checks

Loose wiring and corroded terminals cause half of the intermittent cooling calls I see.

Twice a Year

-

Tighten terminal screws on the power block.

-

Inspect the plug for discoloration.

-

Test voltage against manufacturer spec (208/230 V or 265 V).

-

Verify thermostat sensor placement — must be free of dust.

(Energy.gov electrical safety)

👉 Tony’s Reminder: If your plug looks burnt or smells, replace the outlet. Don’t wiggle it “until next week.”

🧠 5. Airflow & Fan Inspection

Fans pull air across both coils. A small imbalance creates vibration and noise complaints.

-

Check fan blades every 6 months for dust buildup.

-

Spin manually — blades should rotate freely.

-

Lubricate bearings if the manufacturer allows (most modern fans are sealed).

(ACHR News blower maintenance report)

🌡️ 6. Refrigerant & Compressor Health

Unlike mini splits, PTACs are factory-sealed, so you shouldn’t be topping off refrigerant often. But low charge or overheating can show up in these signs:

-

Warm air on “cool” mode.

-

Ice on the evaporator coil.

-

Short cycling (unit turns on/off frequently).

If you suspect a leak, call a technician certified under EPA Section 608 — R-32 requires A2L-rated recovery equipment.

👉 Tony’s Field Note: 90 % of “refrigerant issues” are airflow or drain problems. Check those first before you assume the gas leaked out.

🧱 7. Annual Deep Service

Once a year, schedule a pro tune-up. Here’s what they should cover:

-

Coil deep-clean (inside/out).

-

Electrical inspection.

-

Airflow measurement.

-

Drain flush and slope verification.

-

Temperature differential test (should be 16–22 °F between intake and discharge).

Average cost: $150–$250 per unit — cheap insurance for avoiding $600 compressor failures.

🌦️ 8. Seasonal Checklists

Spring Start-Up

-

Clean filters and coils.

-

Check thermostat calibration.

-

Inspect wall seals for winter cracking.

Summer Peak

-

Monitor condensate flow weekly.

-

Listen for vibration changes.

Fall Transition

-

Switch to heat mode, test the reversing valve if it’s a heat-pump PTAC.

-

Vacuum dust from the electric heater coil.

Winter Storage (if unused)

-

Cover the exterior grille with breathable mesh.

-

Turn off the power to prevent freeze damage.

👉 Tony’s Reminder: A five-minute seasonal check beats a $400 emergency service call every time.

🧩 9. Common Problems & Quick Fixes

| Problem | Likely Cause | Tony’s Fix |

|---|---|---|

| Weak cooling | Dirty filter or coil | Clean both |

| Unit drips inside | Sleeve slope wrong | Re-level sleeve |

| Noise on startup | Loose grille screws | Tighten evenly |

| Musty odor | Mold in the drain pan | Flush with vinegar |

| Short cycling | Thermostat sensor dirty | Wipe gently |

🧾 10. Cost of Neglect vs Maintenance

| Item | Preventive Cost | Neglect Cost |

|---|---|---|

| Filter cleaning | $0–$10 | 15 % higher bills |

| Coil cleaning | $50 | $300 compressor |

| Drain cleaning | $5 | $200 drywall repair |

| Annual tune-up | $200 | $600 replacement |

👉 Tony’s Math: Every $1 spent on maintenance saves $5–$7 in future repairs.

💵 11. Tools & Supplies List

-

Soft brush or coil comb ($10–$15)

-

Non-acidic coil cleaner ($12–$20)

-

Fin comb ($8)

-

Condensate tablets ($5)

-

Foam sealant ($6)

-

Multimeter ($25–$40)

Total investment: under $100 — and you’ll use it for years.

🌎 12. Sustainability & R-32

Keeping your PTAC clean doesn’t just save energy — it cuts greenhouse gas emissions. R-32 units already have a 68 % lower GWP than R-410A, and efficient operation amplifies that benefit.

Hotels that switched to R-32 reported up to 12 % lower power usage and fewer service calls. Small effort, big environmental payoff.

🧠 13. FAQ: Real Questions from Tony’s Jobsites

Q: Can I use bleach on coils?

A: No, it corrodes aluminum. Use coil cleaner only.

Q: How often should I change filters in a hotel?

A: Monthly, minimum — weekly in high-occupancy months.

Q: My PTAC smells musty after winter. Why?

A: Stagnant water in the drain pan. Flush before summer.

Q: Can I power-wash the exterior grille?

A: No — low-pressure rinse only.

Q: How do I quiet a buzzing unit?

A: Check grille screws and mounting rails.

…and 15 more detailed answers covering humidity, energy settings, and heat-pump maintenance.

🧮 14. Long-Term Savings Example

Let’s say you maintain your R-32 PTAC for 15 years.

| Cost Item | Annual | 15-Year Total |

|---|---|---|

| Maintenance | $100 | $1,500 |

| Electricity | $500 | $7,500 |

| Repairs | $50 | $750 |

| Total Ownership | $9,750 |

Compare that to neglect: roughly $12,500 due to higher bills and early replacement.

🏨 15. Case Studies

Florida Hotel

Performed quarterly coil cleanings on 100 R-32 PTACs. Power bills dropped 10 %, and zero drain leaks after hurricane season.

Chicago Apartments

The landlord added PTAC cleaning to the move-out checklist. Cut the replacement rate by half.

Oregon Office Building

Used Energy Star R-32 units with routine maintenance — still original after 14 years.

🧱 16. When to Replace

Even with perfect care, parts age. Replace if you notice:

-

Rising power draw.

-

Rusted coil fins.

-

Frequent breaker trips.

-

Compressor noise.

New R-32 replacements run 8–12 % cheaper to operate and qualify for rebates via DSIRE USA.

🏁 Tony’s Final Checklist

-

✅ Clean filters monthly.

-

✅ Flush drains quarterly.

-

✅ Deep-clean coils yearly.

-

✅ Inspect electrical twice a year.

-

✅ Keep outdoor airflow clear.

-

✅ Register warranty and log service dates.

👉 Tony’s Bottom Line: PTACs don’t die of old age—they die of neglect. Take an hour each month, follow the checklist, and your R-32 unit will hum along quietly for 15 years or more.

Next up, we will learn about the Tax credits and Energy Rebates for R-32 PTAC.