🏡 Introduction: Why Maintenance Matters More Than You Think

When I first installed my Goodman 3 Ton 15.2 SEER2 R-32 Dual-Fuel System, I was excited about its high efficiency and the promise of lower utility bills. For the first few months, everything ran perfectly — quiet, steady, and powerful.

Then summer rolled around. My home didn’t cool quite as fast as before, and the electric bill ticked up just a little. I figured it was normal — until I opened the outdoor condenser and saw it coated in dust and pollen.

That’s when I realized: even the best equipment needs regular care.

Maintenance isn’t just for when something breaks — it’s how you keep your system efficient, reliable, and long-lasting.

Whether you’re running a Goodman R-32 system or another high-efficiency unit, this step-by-step guide covers everything I’ve learned about keeping it running smooth all year round.

🔄 1. The Annual Maintenance Mindset

Every HVAC system has two sides: heating and cooling. Both need seasonal attention.

Skipping maintenance even for one year can cause:

-

Reduced efficiency (higher bills)

-

Dirty coils that trap heat

-

Refrigerant imbalance

-

Early compressor or blower failure

Think of it like your car — if you never change the oil, performance declines long before the engine fails.

🧰 What a Professional Tune-Up Includes

Even if you prefer DIY, it helps to know what pros check during an annual service:

-

Coil and blower cleaning

-

Filter replacement

-

Refrigerant level verification

-

Electrical connection tightening

-

Combustion analysis (for furnaces)

-

Safety and control checks

🌸 2. Spring: Cooling Prep & Coil Cleaning

Icon: 🌤️

When spring hits, it’s time to get your air conditioning ready for summer’s demands.

Here’s my Spring Start-Up Checklist:

✅ Clean the Outdoor Condenser Coils

-

Turn off power at the disconnect.

-

Remove debris and leaves from around the unit (keep 2 feet clearance).

-

Gently spray coils from top to bottom with a garden hose.

-

For tough grime, use a foaming coil cleaner rated for aluminum fins.

Dirty coils reduce your SEER2 efficiency by up to 15%.

✅ Inspect Refrigerant Lines

-

Look for cracks in the insulation on the larger suction line.

-

Replace damaged insulation with R-32-compatible tubing.

✅ Change Filters

Replace filters every 1–3 months. I use MERV 8 pleated filters — good balance of filtration and airflow.

✅ Flush the Condensate Drain

-

Mix 1 cup of white vinegar with 1 gallon of warm water.

-

Pour slowly into the condensate line to prevent algae buildup.

✅ Check Electrical Components

-

Inspect contactor for pitting or corrosion.

-

Verify that all terminals are tight.

-

Replace worn wire connectors or cracked conduit.

☀️ 3. Summer: Airflow & Efficiency Maintenance

Icon: 🌬️

Once temperatures climb, your system runs almost daily — making summer the most important time for airflow and efficiency checks.

🧾 Filter Routine

-

Replace every 30 days during high-use months.

-

Mark a reminder on your phone or thermostat app.

Clogged filters make your blower motor work harder, raising your electric bill and reducing cooling capacity.

🧊 Check the Temperature Split

-

Run the AC for 15 minutes.

-

Measure return air temperature and supply air temperature.

-

The difference should be 18–22°F.

If the split is smaller, you may have:

-

Low refrigerant

-

Dirty coil

-

Restricted airflow

🔇 Listen for Unusual Sounds

Rattling or hissing noises can signal loose panels, duct leaks, or pressure issues.

🌳 Maintain Clearance Around the Condenser

Keep at least 2 feet of clearance around the outdoor unit and 5 feet above it.

🍂 4. Fall: Furnace Prep & System Switchover

Icon: 🔥

When cooling season ends, it’s time to prepare for heating. The dual-fuel system’s gas furnace now takes over.

Here’s how I transition mine each fall:

✅ Clean Burners and Flame Sensor

-

Turn off power and gas.

-

Gently clean burners with compressed air or a soft brush.

-

Use fine steel wool on the flame sensor to remove oxidation.

A dirty flame sensor is one of the most common causes of furnace shutdowns.

✅ Inspect Exhaust Venting

-

Make sure PVC vent pipes are clear and properly sealed.

-

Check for moisture buildup at joints (sign of improper vent slope).

✅ Check Ignition System

-

Watch ignition cycle: the flame should be blue and steady.

-

Yellow or flickering flames may indicate poor combustion or dirty burners.

✅ Lubricate the Blower Motor (if applicable)

Some older models have oil ports on the blower — use a few drops of non-detergent motor oil.

✅ Change Filters Again

Before heating season starts, install a fresh filter to keep the heat exchanger clean.

🔗 National Comfort Institute – Importance of Combustion Testing

❄️ 5. Winter: Comfort & Performance Tune-Up

Icon: 🏠

Winter maintenance ensures your Goodman system stays reliable during freezing temperatures.

🔎 Check Thermostat Accuracy

Compare the reading with a portable thermometer. If there’s a difference of more than 2°F, recalibrate or replace the thermostat batteries.

🧯 Carbon Monoxide (CO) Safety

-

Install a CO detector near sleeping areas and near the furnace.

-

Test it monthly. Replace batteries every year.

🔄 Cycle the System

Run through heat, fan, and cool modes briefly to ensure switching functions properly — especially for dual-fuel setups that alternate between electric cooling and gas heating.

🚪 Check Vents and Returns

Ensure all vents are open and unobstructed by rugs or furniture. Blocked vents restrict airflow and cause uneven temperatures.

🧹 6. Deep Cleaning: Coils, Drains & Blower Assembly

Icon: 🧽

Even with good filters, dust still finds its way inside your system. Once or twice a year, I do a more thorough cleaning.

🌀 Evaporator Coil

-

Turn off power.

-

Remove coil access panel.

-

Use a no-rinse coil cleaner designed for aluminum.

-

Let dry completely before reassembling.

💧 Condensate Drain Pan

-

Flush with warm soapy water.

-

Pour diluted bleach solution (1:10 ratio) through the line to disinfect.

🌫️ Blower Assembly

-

Vacuum dust from blower wheel and housing.

-

Inspect for wobbling or uneven blades.

If you see oily residue or black soot, call a pro — it could indicate motor bearing failure.

⚡ 7. Safety & Electrical Inspection

Icon: ⚙️

Before touching anything electrical, turn off power at the disconnect or breaker panel.

⚡ Electrical Safety Steps

-

Tighten all terminal screws.

-

Inspect wires for cracking, fraying, or discoloration.

-

Check the run capacitor (a bulging top means it’s time for replacement).

-

Test breakers and fuses for continuity.

-

Confirm that the outdoor disconnect box is sealed from moisture.

If you’re not comfortable with electrical testing, schedule a licensed technician annually.

🧪 8. Refrigerant & System Performance

Icon: 🧊

R-32 refrigerant is highly efficient, but it operates under higher pressure than older R-410A. That means checking charge levels requires care.

Why Refrigerant Balance Matters

-

Too little refrigerant = poor cooling, frozen coils

-

Too much refrigerant = high pressure, compressor stress

Leave this one to the pros.

A licensed HVAC technician will:

-

Connect gauges to measure system pressure.

-

Check superheat and subcooling levels.

-

Ensure the charge matches factory specs.

🧯 9. Pro Maintenance vs. DIY: Finding the Balance

Some tasks are perfect for homeowners; others need professional tools and safety training.

| Task | DIY-Friendly | Hire a Pro |

|---|---|---|

| Filter replacement | ✅ | — |

| Cleaning condenser coils | ✅ | — |

| Electrical inspection | ⚠️ Basic visual only | ✅ Detailed |

| Refrigerant check | ❌ | ✅ Required by law |

| Combustion testing | ❌ | ✅ |

| Blower motor lubrication | ✅ | — |

| Duct sealing & balancing | ⚠️ Basic | ✅ Full pressure test |

If you like to stay hands-on, you can do 60–70% of maintenance yourself. But always schedule one professional inspection a year — especially for safety and refrigerant checks.

💡 10. Mike’s Takeaway: Maintenance Is Cheaper Than Repair

Maintenance might not be glamorous, but it’s powerful. A little time each season keeps your home comfortable and your system efficient for years.

Here’s what I’ve learned firsthand:

-

My system runs smoother when filters are clean.

-

My utility bills drop when coils and ducts stay clear.

-

And I haven’t had a single breakdown since I started regular seasonal care.

Preventive maintenance costs far less than repairs — a $100 tune-up now can prevent a $1,000 compressor failure later.

“Maintenance isn’t fixing what’s broken — it’s making sure it never breaks down when you need it most.”

Goodman builds solid systems, but consistent care keeps them great for decades.

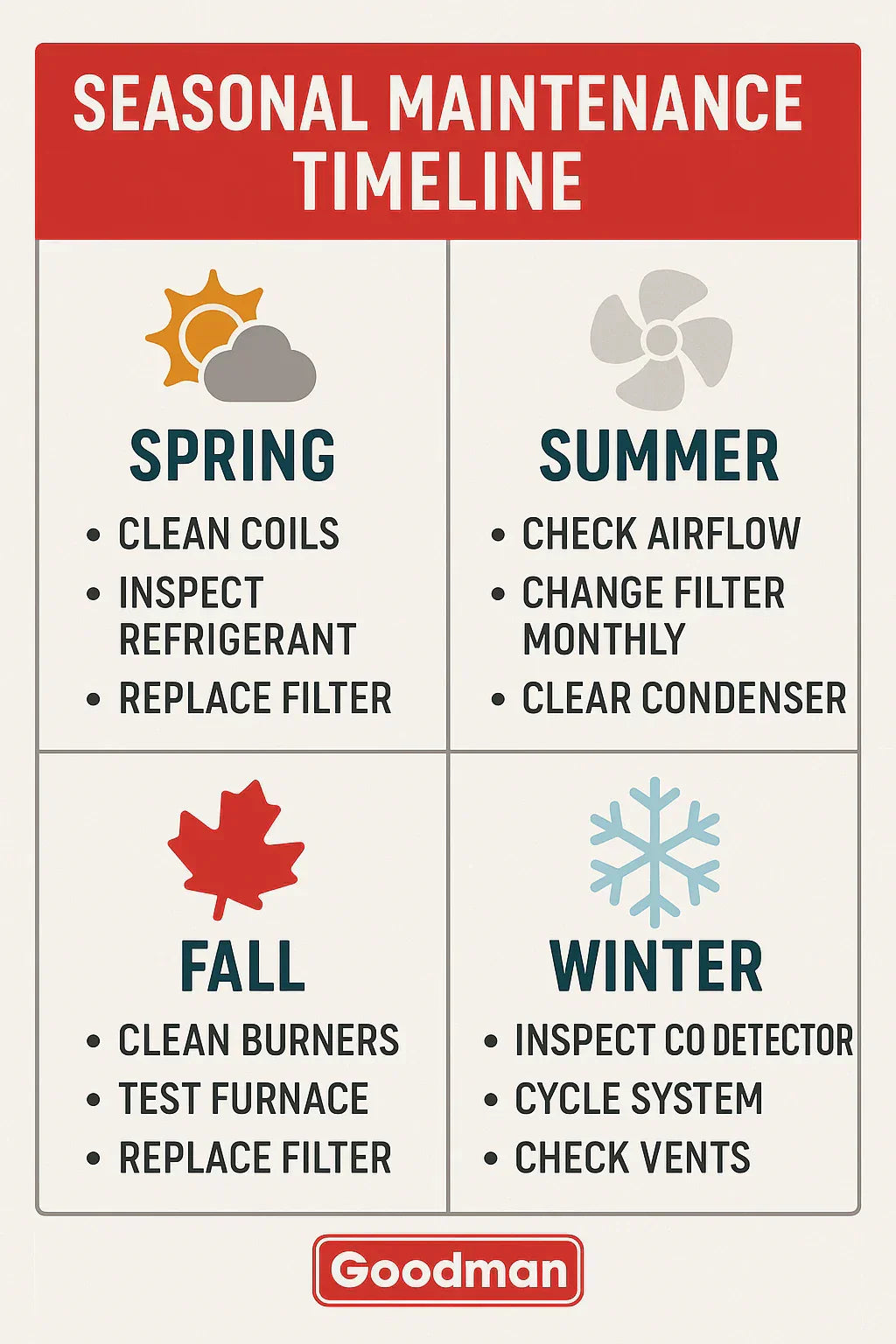

🗓️ Seasonal Maintenance Summary

| Season | Key Tasks | Why It Matters |

|---|---|---|

| Spring | Clean coils, replace filters, inspect drains | Prepares for cooling efficiency |

| Summer | Test temp split, monitor airflow, clear condenser | Maintains SEER2 performance |

| Fall | Clean burners, test furnace, replace filters | Ensures safe heating |

| Winter | Inspect CO detector, cycle system, check vents | Keeps dual-fuel balance steady |

🧩 Infographic: Seasonal Maintenance Timeline

Sections:

-

Spring: Coil cleaning, refrigerant inspection

-

Summer: Airflow & filter routine

-

Fall: Furnace prep, ignition checks

-

Winter: Comfort testing, CO safety

Design: Goodman red-gray-white palette, icons (leaf, sun, flame, snowflake), clean homeowner-style layout.

In the next topic we will know more about: What Mike Did When His System Stopped Cooling: A Troubleshooting Guide