Most homeowners and even many installers think that placing the outdoor AC unit “near the house” is enough.

Jake knows this is wrong.

Clearance is the foundation of:

-

system efficiency

-

compressor reliability

-

airflow performance

-

noise control

-

long-term durability

And here’s the part people miss:

R-32 condensers are more sensitive to airflow, recirculation, and obstruction than older refrigerant systems.

So clearance isn’t optional — it’s science.

This guide breaks down Jake’s precise clearance distances and why each one matters, using the Goodman 2.5 Ton 13.4 SEER2 R-32 condenser as the baseline model.

🧊 1. Why R-32 Systems Have Stricter Clearance Requirements

R-32 refrigerant operates at:

-

higher energy density

-

higher discharge temperature

-

higher vapor pressure

This means:

-

Better efficiency (when installed correctly)

-

More sensitive airflow needs (when installed incorrectly)

Jake says:

“R-32 gives you better efficiency… but only if you give it the space to breathe.”

Even a 6-inch mistake can cost you 10–20% efficiency or shorten compressor life.

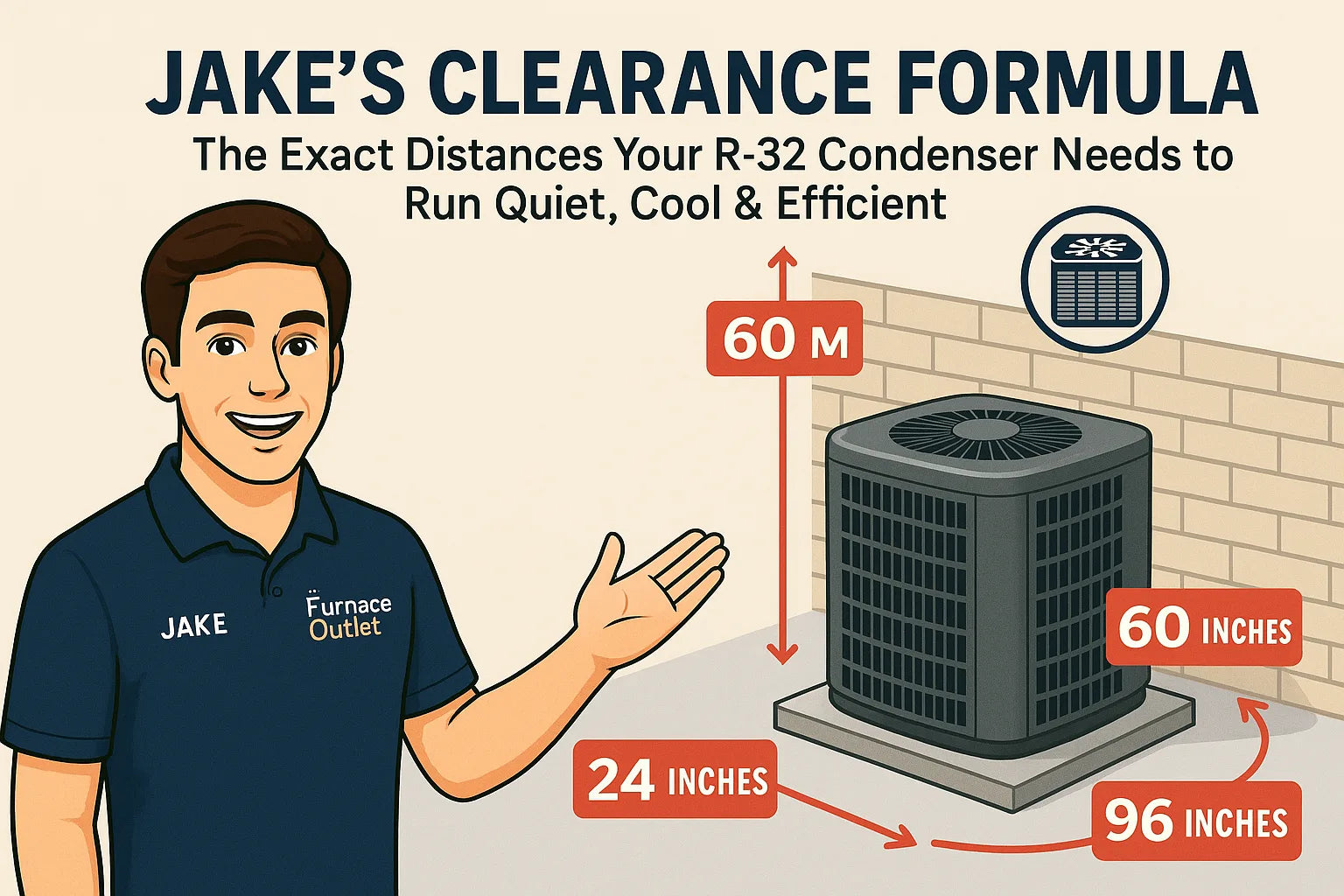

📏 2. Jake’s Clearance Formula (The Quick Version)

Jake uses a simple rule homeowners can memorize:

24 – 36 – 60 – 96

(Front – Sides – Top – Obstruction Radius)

Here’s what it means:

-

24 inches (front) = minimum service + intake airflow

-

36 inches (sides) = re-circulation prevention

-

60 inches (top) = vertical discharge clearance

-

96 inches (radius) = no large walls, fences, or objects directly blocking airflow

We’ll break this down in detail below.

🟥 3. Front Clearance: 24 Inches Minimum (Service + Air Intake)

Jake gives the condenser 24 inches in front — no excuses, no compromise.

Why 24 Inches?

Because the front:

-

pulls 80% of intake airflow

-

houses access panels

-

holds the service valves

-

contains the coil wrap

-

contains the fan intake perimeter

If the front is blocked:

-

static pressure rises

-

compressor runs hotter

-

coil efficiency drops

-

system becomes louder

-

SEER2 rating falls

Jake’s exact rule:

“If I can’t fully kneel in front of the condenser to service it, it’s too close.”

Verified Reference Link:

Goodman Installation Instructions (General Clearances)

https://www.goodmanmfg.com/

🟦 4. Side Clearance: 36 Inches Minimum (The ‘Quiet Side’)

Jake calls the side clearance the quiet side, because airflow restrictions cause:

-

turbulent fan noise

-

high static pressure

-

motor strain

-

rattling panels

He gives 36 inches minimum on each side of the condenser.

Why 36 Inches?

Because R-32 systems reject more BTUs per cubic foot of refrigerant. They need more lateral space to dissipate heat.

Side Obstructions Include:

-

walls

-

fences

-

gas meters

-

bushes

-

grill stations

-

garbage bins

-

hydrangea plants (yes, really)

Jake has removed more plants than condensers for airflow problems.

Jake’s rule:

“If you can’t comfortably walk around both sides of the unit, it’s too tight.”

⬆️ 5. Top Clearance: 60 Inches Minimum (Vertical Discharge Zone)

Vertical clearance is the most misunderstood measurement.

Jake refuses to install a condenser with:

-

decks overhead

-

overhangs

-

enclosed porches

-

balcony structures

-

low roof eaves

Minimum Requirement:

60 inches above the top fan grille

Why 60 Inches?

The R-32 condenser ejects hot air straight upward. If that hot air hits an obstruction, it recirculates back into the coil intake.

This is the #1 cause of:

-

short cycling

-

compressor overheating

-

poor EER/SEER2 performance

-

higher utility bills

-

early compressor death

Jake uses a laser line to measure vertical clearance before he approves the install spot.

Verified Reference Link (Fan Performance Standards):

AMCA (Air Movement and Control Association) – Overhead Clearance Impact

https://www.amca.org/

🧱 6. Obstruction Radius: 96 Inches (8 Feet) — The Wall Rule

The obstruction radius is a concept Jake teaches every homeowner.

It means:

No major obstruction within 8 feet of the condenser in any direction.

Obstructions include:

-

tall retaining walls

-

large hedges

-

fences

-

vehicle parking

-

sheds

-

privacy walls

-

stairs

Anything that traps or blocks airflow counts.

Why 8 Feet?

During operation, a condenser creates a high-volume air plume.

Obstructions cause:

-

hot-air recirculation

-

turbulent pressure zones

-

inefficient coil heat transfer

-

hotter compressor dome temperatures

Jake will not install a condenser inside a “pocket” of obstructions.

The worst-case scenario:

A 4-sided enclosure around the condenser.

This is instant SEER2 failure.

🌿 7. Landscaping Clearance (The Plant + Leaf Rule)

Plants breathe. So do condensers.

Most homeowners think putting bushes around the unit “hides” it.

Jake has spent years un-hiding failed units for this exact reason.

Landscaping Requirements:

-

No shrubs within 36 inches

-

No vines or ivy (ever)

-

No leaf piles

-

No bark dust (gets sucked into coils)

-

No tall grass

-

No decorative fencing closer than 30 inches

Jake also requires 12 inches of rock perimeter around every condenser to prevent weed overgrowth.

Verified Reference Link

EPA EnergyStar AC Landscaping Guidelines

https://www.energystar.gov/

🧯 8. Fire & Safety Clearance (Gas Meters, Electrical Boxes, Vents)

Jake always checks compliance with spacing from:

-

gas meter

-

exhaust vents

-

electrical service panels

-

dryer vents

-

generator intakes

-

oil fill pipes

Minimum Distances:

-

36 inches from gas meter

-

36 inches from electrical panels

-

60 inches from dryer vents

-

10 feet from generator air intake

-

Avoid downward-facing vents entirely

Dryer lint is the #1 condenser killer Jake sees in older homes.

Verified Reference Link

National Fuel Gas Code (NFPA 54)

https://www.nfpa.org/

📡 9. Line Set Clearance (Pipe Routing Matters, Too)

Jake gives line set clearance equal priority to condenser clearance.

Minimum Line Set Requirements:

-

No crushing or bending radius below 10× diameter

-

12 inches above ground

-

6-inch wall standoff

-

Insulation with UV jacket in sunny regions

-

Avoiding tight 90° turns

A poor line set layout can ruin the best condenser install.

Verified Reference Link

AccuTools / BluVac – Line Set Best Practices

https://accutools.com/

🔊 10. Noise Control Clearances (How Jake Makes Condensers Whisper)

Icon: 🔊

Noise is airflow + vibration.

Jake ensures silence by:

1. Avoiding wall “echo chambers”

No hard reflective surfaces closer than 30 inches.

2. Using anti-vibration pads

Especially in elevated installations.

3. Positioning the condenser on the “quiet side”

Away from bedroom windows or neighbor boundaries.

4. Maintaining line set spacing

Line sets touching a wall will transmit vibration into the home.

Jake says:

“The quieter the unit, the better the install.”

🧰 11. Jake’s Installation Scenarios (Exactly Where He Places the Unit)

Here’s how Jake applies the formula in real-world situations.

Scenario A: Between Two Houses

-

36 inches from house #1

-

36 inches from house #2

-

8 feet of clear air in front

-

Rock perimeter under and around pad

Scenario B: Against a Fence Line

-

36 inches from fence

-

60 inches vertical clearance

-

24 inches service access

-

No bushes

-

No fence height above condenser top

Scenario C: Under a Deck (Jake Will Not Do This)

Jake refuses deck installs unless:

-

deck is 8+ feet high

-

ventilation is fully open on all sides

-

no plenum effect is created

Anything less traps hot air.

Scenario D: Corner of a House

Jake angles the condenser so the discharge stream doesn’t hit the walls.

This lowers:

-

noise

-

recirculation

-

coil temperature

🔚 12. Final Word from Jake

Jake’s clearance formula is simple, but most installers skip it.

He says:

“If your condenser can’t breathe, it can’t cool. Good clearance is free efficiency.”

Giving an R-32 unit proper space ensures:

-

lower noise

-

lower head pressure

-

longer compressor life

-

higher SEER2 performance

-

fewer service calls

Good clearance isn’t decoration — it’s engineering.

Buy this on Amazon at: https://amzn.to/47dm4yJ

In the next topic we will know more about: The 7 Mistakes Jake Sees in DIY Installs—and How He Fixes Them in Under an Hour