👋 Introduction: Mike’s Story

Hey folks, Mike Sanders here. If you’re reading this, chances are you’re considering a new AC system—or you’re curious whether you can install a Goodman 2.5 Ton 13.4 SEER2 condenser yourself.

I’ll be honest with you: installing an AC condenser isn’t the same as putting together a piece of furniture from the hardware store. It’s a serious job with safety risks, building codes, and refrigerant laws involved.

That said, there are parts of the job you can do as a homeowner to save money, and I’ll share the lessons I learned when I prepped and helped with my own install.

This article covers:

-

Prep work before the condenser arrives,

-

Key checks for compatibility,

-

Electrical and refrigerant considerations,

-

Step-by-step installation flow,

-

Where to stop DIY and call in the pros,

-

The mistakes I made (so you don’t repeat them).

🏡 Pre-Installation Prep: What You Need to Know

🔹 Permits and Codes Matter

First lesson: check local codes. In most U.S. jurisdictions, you’ll need a permit for a condenser install. If you skip it, you could face fines or fail inspections when selling your home.

👉 Check your city or county website for permitting info, or visit the International Code Council to understand standards that many regions adopt.

🔹 Location and Placement

Clearance is critical for airflow:

-

Leave at least 2 feet around the condenser on all sides.

-

Don’t place it under low decks or overhangs.

-

Avoid spots with heavy sun exposure if possible.

Mike’s tip:

“I thought hiding my condenser behind shrubs was smart—it looked nice, but the airflow tanked and efficiency dropped. Big mistake.”

🔹 Tools and Supplies to Prep

-

AC condenser pad (pre-fab composite or poured concrete).

-

Level and gravel (for a solid base).

-

Disconnect box and whip (for electrical).

-

Line set (if not re-using existing, and only if compatible with R-32).

-

Sealant/insulation for penetrations.

👉 Home Depot has a comprehensive AC install supplies list.

📏 Sizing & Compatibility Checks

🔹 Match Condenser to Air Handler

A 2.5 ton Goodman condenser needs to pair with an air handler (or furnace with coil) designed for 30,000 BTUs.

-

Mismatching tonnage = inefficiency and premature wear.

-

Verify both units are rated for R-32 refrigerant.

🔹 Line Set Compatibility

R-32 requires proper line set sizing and cleanliness. Re-using old R-410A lines may not be safe unless thoroughly flushed and verified.

Mike’s lesson:

“I assumed my old copper lines would work. My installer laughed—they needed replacement because of contamination and sizing issues.”

👉 AHRI (Air-Conditioning, Heating, and Refrigeration Institute) explains system matching here: AHRI Directory.

⚡ Electrical Setup & Safety

🔹 Dedicated Circuit

AC condensers require a dedicated 240V circuit, with breaker size matching manufacturer specs (usually 20–40 amps for a 2.5 ton).

🔹 Disconnect Box

Install a disconnect within sight of the condenser for safety.

🔹 Proper Grounding

Improper grounding risks fire and electrocution. Always follow NEC (National Electric Code) standards.

Mike’s near-miss:

“I thought my old breaker would handle the new condenser—it tripped constantly. Turns out Goodman required a slightly higher amp breaker. Lesson learned: match specs exactly.”

👉 Learn more from NFPA National Electric Code.

🧊 Refrigerant & Line Set Considerations

🔹 Pre-Charged vs. Charged by Tech

Some systems come pre-charged with refrigerant, but line set length and handling can require adjustments.

-

For R-32, only certified HVAC techs can handle charging.

-

DIY refrigerant handling is illegal in the U.S. under EPA Section 608.

👉 EPA Section 608 Certification Info.

Mike’s advice:

“Don’t touch the refrigerant side unless you’re licensed. Do the prep, then let the pro vacuum, test, and charge the lines.”

🔹 Leak Testing & Vacuum

Techs will:

-

Pressure test with nitrogen,

-

Pull a vacuum to remove moisture/air,

-

Release R-32 charge into the system.

📦 Step-by-Step Installation Highlights

Here’s the big picture flow:

-

Prepare the Pad

-

Lay gravel, level it, set condenser pad.

-

-

Position the Condenser

-

Place unit, ensuring airflow clearance.

-

-

Install Electrical Disconnect & Wiring

-

Run whip from disconnect to condenser.

-

-

Run Line Set

-

Route copper lines through wall penetrations.

-

Seal with insulation to prevent leaks.

-

-

Connect Low-Voltage Control Wiring

-

Thermostat wires to control board.

-

-

Professional Refrigerant Startup

-

Leak test, vacuum, charge adjustment.

-

Mike’s tip:

“Measure twice, cut once—especially with copper lines. I kinked a line on my first attempt and had to buy another set.”

👉 Goodman’s official installation guides are detailed references.

👷 DIY vs. Pro: Where to Draw the Line

👍 Homeowner-Friendly Tasks

-

Site prep (pad, gravel, leveling).

-

Mounting disconnect box (licensed electrician should finish wiring).

-

Routing line set (tech must handle final connections).

-

Sealing penetrations.

🚫 Leave to the Pros

-

Refrigerant charging.

-

Final electrical tie-ins.

-

Load calculations (Manual J, S, D).

Mike’s advice:

“Save money by doing grunt work—let pros handle the parts that could burn your house down or void your warranty.”

🚫 Common Mistakes Homeowners Make

-

Placing the unit too close to walls, fences, or shrubs.

-

Using undersized or contaminated line sets.

-

Forgetting permits and inspections.

-

Ignoring manufacturer clearances for service access.

-

Improperly sloped line sets, leading to oil traps.

Mike’s real-life mistake:

“I planted hedges right after install to hide the unit. Within weeks, airflow dropped and efficiency tanked. I had to cut them back—wasted effort.”

👉 Energy Star covers condenser placement tips here: Energy Star AC Guidance.

✅ Mike’s Lessons Learned & Final Tips

-

Plan ahead: Don’t unbox your condenser until you’ve mapped out pad, wiring, and lines.

-

Read the manual: Goodman provides diagrams for clearances, breaker sizing, and wiring.

-

Don’t cheap out on ductwork: Tight ducts save more energy than jumping from 13.4 to 16 SEER2.

-

Respect refrigerant laws: R-32 is efficient, but not for DIY handling.

Mike’s wrap-up:

“Installing a condenser isn’t just dropping a box on a slab—it’s setting up the heart of your home’s comfort. Prep well, work with a pro where needed, and your Goodman will keep you cool for years.”

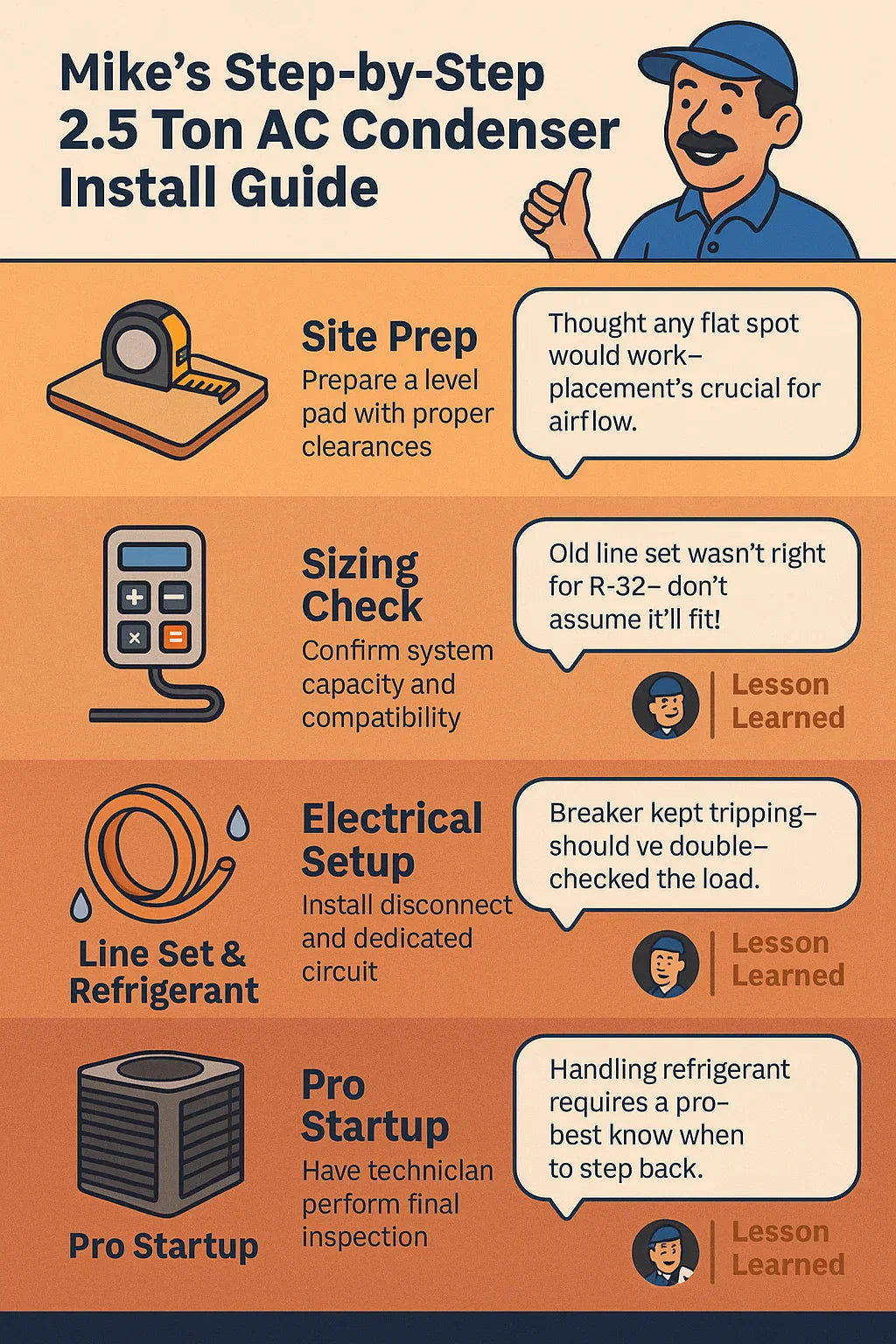

📊 Infographic Idea

Title: “Mike’s Step-by-Step 2.5 Ton AC Condenser Install Guide”

-

Flow diagram: Pad Prep → Placement → Electrical → Line Set → Pro Startup

-

Icons: tape measure 📏, breaker ⚡, copper coil 🧊, wrench 🔧, checklist ✅

-

Mike’s “Lesson Learned” callout bubbles.

🏁 Conclusion

Installing a Goodman 2.5 Ton 13.4 SEER2 R-32 condenser is a project that combines DIY opportunities with pro-only tasks. You can save money by handling site prep, pad setup, and basic routing—but leave refrigerant and final electrical to licensed experts.

If you follow manufacturer specs, respect codes, and learn from mistakes (like I did), you’ll end up with a system that’s efficient, safe, and built to last.

In the next topic we will know more about: How Much Does a 2.5 Ton AC Cost in 2025? Equipment, Labor & Energy Use Explained