🏠 Introduction: From Research to Reality

When I decided to install my own Goodman 3 Ton 15.2 SEER2 R-32 Dual-Fuel System, I knew it wasn’t a small weekend project. I’m a hands-on homeowner, not a certified HVAC technician — but I’ve learned a lot through years of maintenance, small installs, and countless hours of reading manufacturer manuals.

This guide isn’t a replacement for a licensed professional — especially when it comes to gas connections or refrigerant handling — but it’s the kind of practical, real-world roadmap I wish I’d had when starting out.

The Goodman dual-fuel system combines an R-32 air conditioner condenser, a matching vertical evaporator coil, and a 96% AFUE 100,000 BTU natural gas furnace. It’s an energy-efficient, comfort-balanced powerhouse — but getting it installed correctly takes careful planning, patience, and the right tools.

⚙️ 1. Understanding the System Before You Begin

🔍 What “Dual-Fuel” Really Means

A dual-fuel system pairs an electric heat pump or air conditioner with a gas furnace, allowing your home to automatically switch between electric cooling and gas heating depending on outdoor temperature and efficiency needs.

This Goodman setup uses R-32 refrigerant, known for higher efficiency and lower global warming potential (GWP) compared to R-410A.

-

AC/Condenser Model: GLXS4BA3610

-

Coil Model: CAPTA3626C3 (Vertical)

-

Gas Furnace Model: GR9T961005CN

Each component works together seamlessly — but only if you match airflow, refrigerant line size, and electrical load properly.

🧮 Sizing Check

Before you even think about cutting or connecting anything, confirm that your 3-ton capacity (36,000 BTU) system matches your home’s needs. Oversized systems short-cycle and waste energy, while undersized ones run constantly.

👉 Use an online load calculator like Energy Vanguard’s Manual J resource or have an HVAC pro run a Manual J heat load analysis to double-check.

📦 2. Preparing for Installation

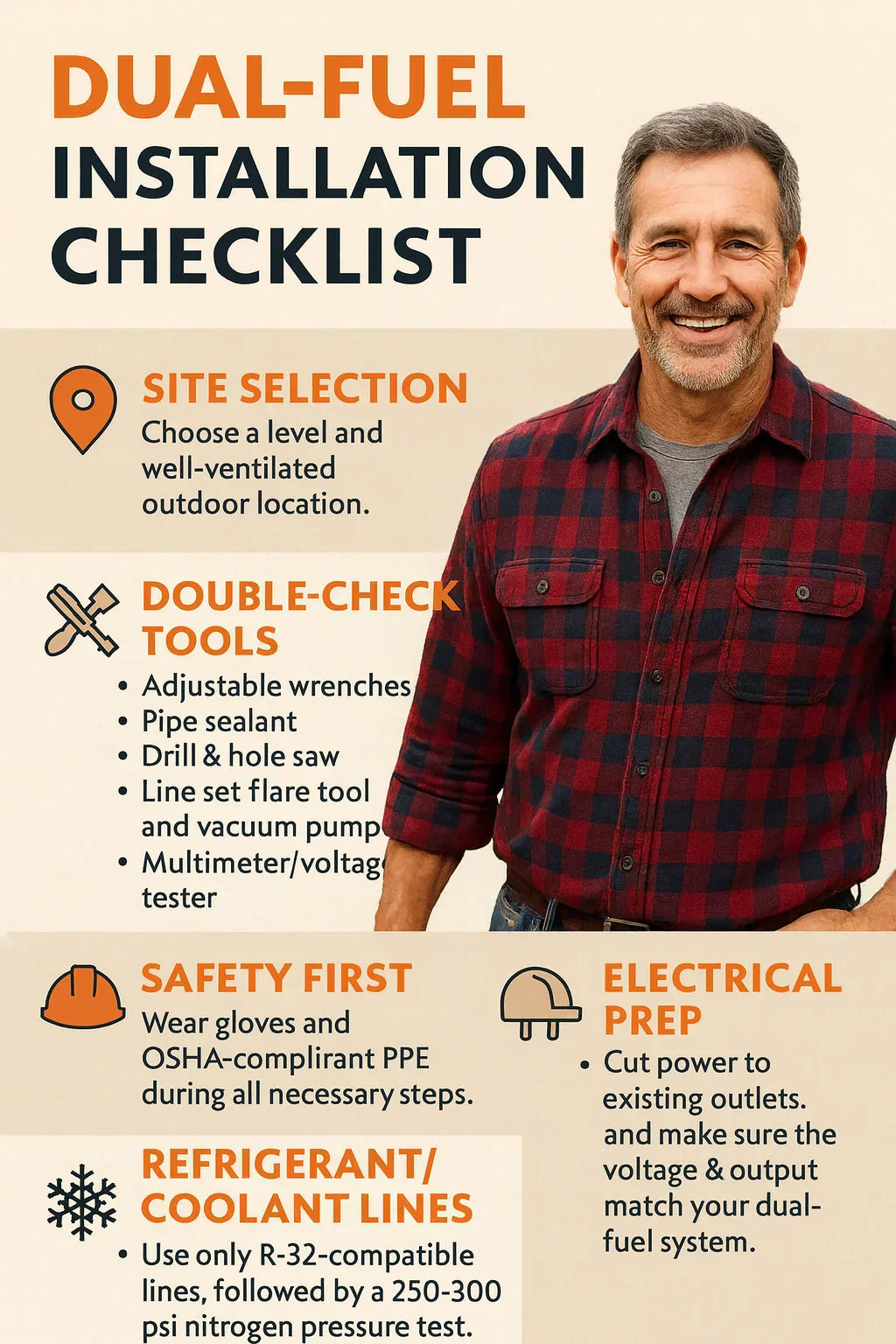

🧰 Tools & Materials Checklist

Here’s what I gathered before starting:

-

Adjustable wrenches & socket set

-

Drill & hole saw

-

¾" PVC pipe (for condensate drain)

-

Sheet metal screws & foil tape

-

Level & measuring tape

-

Electrical conduit, wire nuts, and disconnect box

-

Refrigerant line set (R-32 compatible)

-

Vacuum pump & micron gauge

-

Torque wrench

-

Nitrogen tank (for pressure testing)

-

Pipe dope or thread sealant for gas lines

-

Digital multimeter

You’ll also need PPE — gloves, safety glasses, and hearing protection.

📍 Site Prep: Location & Clearance

I chose a shaded area on the north side of my home for the condenser, ensuring:

-

Minimum 12 inches of clearance on all sides

-

5 feet above for airflow

-

Solid, level concrete or composite pad

Inside, the furnace and coil sit in a dedicated utility closet with:

-

24" front service clearance

-

Proper return and supply duct sizing

-

Adequate combustion air (verified via local building code)

🧩 3. Step-by-Step: Installing the Furnace and Coil

🔧 Step 1: Setting the Furnace in Place

I started with the GR9T961005CN gas furnace — the heaviest component. Position it so the front panel faces outward for service access.

Check for:

-

Level placement (use shims if needed)

-

Return air duct alignment

-

Flue vent direction (upflow or horizontal)

Then, attach the vertical coil (CAPTA3626C3) on top using foil tape and self-tapping screws to create an airtight seal.

🔥 Step 2: Connecting Gas Lines (with Caution)

Gas connections are one of the few steps I always recommend leaving to a licensed plumber or HVAC tech. Incorrect installation can cause leaks, fire, or carbon monoxide hazards.

Still, here’s what I observed during my install:

-

Black iron gas line connected via flexible stainless connector

-

Thread sealant used only on male iron pipe threads

-

Leak testing performed using soap solution before ignition

🌀 Step 3: Drain Line and Coil Connections

I connected a ¾" PVC drain line to the coil’s primary outlet, ensuring a 1/4" per foot downward slope.

Add a P-trap to prevent negative pressure from drawing air into the drain.

Pro tip: Test by pouring water through before sealing everything.

⚡ 4. Wiring & Electrical Connections

🔌 Step 1: Power Supply and Breakers

This Goodman system runs on 240V for the condenser and 120V for the furnace blower.

I ran a dedicated 30A circuit for the condenser and a 15A for the furnace.

-

Install a weatherproof disconnect box near the outdoor unit

-

Route metallic conduit to protect wiring

-

Bond the system to the house ground

🔗 Reference: National Electrical Code (NEC) Article 440 – HVAC Equipment

🧠 Step 2: Thermostat Wiring

My dual-fuel setup uses a 7-wire connection to a smart thermostat (Honeywell T10 Pro).

Here’s the basic layout:

-

R – 24V Power

-

C – Common

-

Y/Y2 – Compressor stages

-

G – Blower fan

-

W/W2 – Gas furnace

-

O/B – Reversing valve (for heat pump, if equipped)

Always label wires before removal — trust me, future you will thank you.

❄️ 5. Installing the Outdoor R-32 Condenser

🧱 Step 1: Set the Pad and Mount the Unit

The GLXS4BA3610 condenser sits on a vibration-isolated pad.

Make sure it’s perfectly level and elevated above grade to prevent flooding during heavy rain.

Secure with anti-vibration brackets if local code requires.

🔗 Step 2: Line Set Connections (Refrigerant Piping)

Use R-32 rated copper lines — usually 3/8” liquid and 3/4” suction for a 3-ton unit.

Run lines carefully through an exterior wall sleeve to prevent kinking.

Before tightening:

-

Purge with nitrogen to avoid oxidation

-

Torque flare fittings per Goodman specs

-

Perform pressure test (250–300 psi nitrogen) for leaks

🌬️ Step 3: Evacuation and Charging

With the lines sealed and tested:

-

Connect a vacuum pump to pull down to 500 microns.

-

Close valves and verify pressure holds steady (no leaks).

-

Release the factory pre-charged R-32 refrigerant into the system.

R-32 has a higher operating pressure than R-410A, so always follow manufacturer charge tables.

⚠️ Important: Only EPA Section 608-certified techs can legally handle refrigerant. As a DIYer, I supervised this step with a licensed technician.

🔗 Reference: EPA Section 608 Refrigerant Regulations

🔥 6. Startup and Testing

After wiring and refrigerant charging were complete, it was time for system testing.

🧭 Step 1: Verify Airflow

Use a simple anemometer at supply vents or check static pressure with a manometer.

Typical static pressure for most Goodman systems should be 0.5–0.8 inches WC.

If pressure’s too high:

-

Check for dirty filters or undersized ducts.

If too low: -

Inspect for duct leaks or disconnected boots.

🔗 Resource: Energy.gov Duct Sealing Guide

🌡️ Step 2: Check Temperature Split

Run cooling mode for 15 minutes, then measure:

-

Return air temp: e.g., 78°F

-

Supply air temp: e.g., 58°F

→ 20°F temperature split = ideal performance

🔥 Step 3: Furnace Heating Test

Switch to heating mode. The gas furnace should:

-

Ignite smoothly

-

Reach steady flame with no noise

-

Exhaust through PVC vent without leaks

If you smell gas or see yellow flames, shut off immediately and call a pro.

🧽 7. Post-Install Finishing Touches

🧾 Label Everything

Label electrical breakers, disconnects, and thermostat wires.

Future maintenance (or resale) will be much easier.

🧊 Insulate the Line Set

Wrap the suction line with UV-rated insulation.

For outdoor runs, seal joints with weather-resistant tape.

🧯 Install a Surge Protector

A small investment that protects compressors and control boards from power surges.

🧼 8. Maintenance Tips After Installation

A successful installation is just the beginning.

To keep your Goodman R-32 system performing efficiently, I follow this simple routine:

| Season | Maintenance Task | Why It Matters |

|---|---|---|

| Spring | Clean condenser coils, test cooling mode | Prevents high head pressure |

| Summer | Replace filters monthly | Maintains airflow |

| Fall | Flush condensate drain, inspect gas venting | Preps for heating |

| Winter | Check furnace flame sensor | Ensures safe combustion |

💡 9. Common Mistakes I Almost Made (and How to Avoid Them)

-

Skipping the nitrogen purge — causes black carbon flakes inside coils.

-

Forgetting to trap the condensate line — leads to water backup.

-

Using old thermostat wire — mine had brittle insulation that caused a short.

-

Not sealing duct joints properly — wasted airflow and added noise.

-

Improper coil orientation — caused refrigerant oil pooling until corrected.

Learning these lessons the hard way reminded me that small oversights can have big consequences.

🧠 10. Final Thoughts: What I’d Tell Any Homeowner

Installing a Goodman 3 Ton R-32 Dual-Fuel System is absolutely doable for a capable homeowner — with respect for safety, code compliance, and professional limits.

Here’s my biggest takeaway:

“Do as much as you safely can — and know when to call in help.”

I handled the prep, wiring, ducting, and drainwork confidently. But for refrigerant charging and gas hookup, I partnered with a certified pro. That’s what makes this a smart DIY, not a reckless one.

In the next topic we will know more about: SEER2 Explained: The Impact of Efficiency on Your Utility Costs