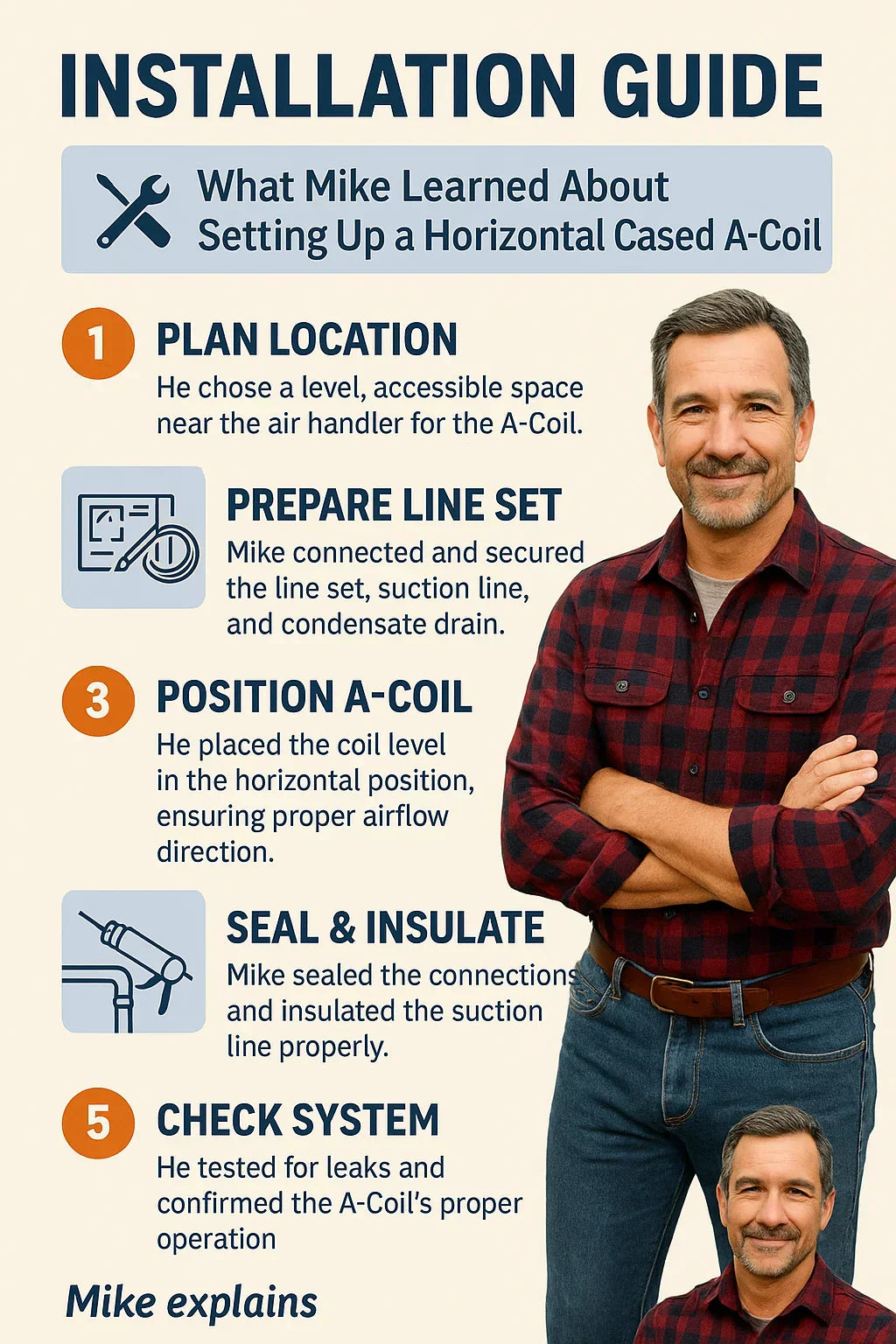

Hi, Mike here. If you’ve ever wondered what it’s like to install a Goodman horizontal cased A-Coil (like the CHPTA4830C3 rated for R-32 refrigerant), you’re in the right place.

Now, I’m not going to sugarcoat it—this is not the kind of Saturday DIY project you knock out without some planning. Installing an A-Coil is part mechanical, part science, part patience. But if you understand the steps, you’ll know what to expect, what’s worth doing yourself, and when to call a pro.

In this guide, I’ll walk you through everything I learned when I set up my horizontal cased coil—the good, the bad, and the “wish I’d done that differently.”

1. 👋 Why I Upgraded to a Horizontal Cased A-Coil

When I first started researching, I had an older vertical coil in a tight closet space. Switching to a horizontal cased coil made sense because:

-

My air handler sat in the attic, where space runs side-to-side, not up-and-down.

-

Horizontal coils are easier to service in low-clearance spaces.

-

A cased design (factory cabinet around the coil) keeps air flowing properly and simplifies installation.

Most importantly, the Goodman CHPTA series is already R-32 compatible—which means I won’t need another coil swap when refrigerant standards shift (EPA AIM Act).

2. 📦 Unboxing & Pre-Check

Before you even think about cutting ductwork or hooking up refrigerant lines, check your equipment.

Here’s what I do right out of the box:

-

Inspect the casing for dents or damage from shipping.

-

Check the coil size/tonnage—mine was rated 3.5–4 tons, a perfect match for my outdoor condenser.

-

Look at the built-in TXV (thermal expansion valve). Goodman’s come pre-installed, which is a huge plus.

-

Verify refrigerant rating—yes, this one is R-32 ready.

-

Confirm model number against your order paperwork.

I’ve seen guys skip this, install the wrong coil, and not realize until they try to start it up. That’s a nightmare you don’t want.

3. 📐 Planning the Install

Horizontal coils need proper planning before you even move them into place.

Key considerations:

-

Location: In attics or crawlspaces, you want enough clearance to slide the coil in and still open access panels later.

-

Drainage: The coil creates condensation. The drain pan must slope toward the drain. No slope = standing water = mold or ceiling leaks.

-

Duct connections: Measure twice, cut once. The coil casing needs to line up square with your ductwork.

ASHRAE guidelines stress that improper coil positioning is a leading cause of reduced efficiency (ASHRAE).

4. 🔧 Tools & Safety Gear

Here’s what I had on hand:

-

Wrenches, nut drivers, and screwdrivers

-

Cordless drill

-

Sheet metal snips (for duct adjustments)

-

Tubing cutter

-

Refrigerant gauges and hoses

-

Level (critical for drainage slope)

-

Vacuum pump (if you’re opening refrigerant lines)

-

Foil tape and duct mastic

Safety gear: gloves, safety glasses, dust mask, and knee pads (trust me, if you’re working in an attic, you’ll thank me).

If you’re not EPA-certified, you should not handle refrigerant charging. That’s one job best left to a licensed pro (EPA Section 608).

5. 🏗 Step-by-Step Installation

Here’s the meat of it—how I got my coil installed.

Step 1: Remove Old Coil (if replacing)

-

Shut off power.

-

Disconnect refrigerant lines (after proper recovery).

-

Detach duct connections.

-

Slide out old coil.

Step 2: Position the New Coil

-

Slide the cased coil into place.

-

Make sure the orientation arrow matches airflow direction.

-

Use your level to set a slight slope toward the drain outlet.

Step 3: Connect Ductwork

-

Secure supply and return ducts with sheet metal screws.

-

Seal joints with mastic or foil tape. Air leaks = lost efficiency.

Step 4: Attach Refrigerant Lines

-

Connect suction and liquid lines.

-

Braze carefully (if required), then insulate.

-

Pressure test for leaks before charging.

Step 5: Connect Condensate Drains

-

Primary drain to a safe disposal point (outdoors or plumbing drain).

-

Secondary (emergency) drain as backup.

-

Test with a cup of water before startup.

6. ⚙️ The TXV Advantage

The built-in TXV is one of my favorite parts of this coil.

-

It automatically meters refrigerant flow.

-

Prevents liquid refrigerant from reaching the compressor.

-

Adjusts for load changes (like hot afternoons vs cool evenings).

Goodman’s pre-installed TXV means fewer field mistakes and better efficiency (Goodman MFG).

7. 💧 Drainage & Moisture Control

One of the biggest lessons I learned: don’t underestimate drainage.

If your drain pan isn’t sloped properly, water backs up and causes headaches. I added a float switch on the secondary drain line. That way, if the primary clogs, the system shuts down before flooding the attic.

According to HVAC.com, clogged condensate lines are one of the most common causes of AC breakdowns.

8. 🔌 Electrical & Control Checks

Before firing up the system:

-

Confirm thermostat wires are secure.

-

Double-check blower motor settings (correct CFM for coil tonnage).

-

Ensure coil cabinet is grounded.

It’s not glamorous, but skipping electrical checks can cause nuisance shutdowns later.

9. 🚀 First Startup & Testing

Here’s my startup checklist:

-

Open refrigerant valves.

-

Power on system.

-

Monitor gauges for correct suction/discharge pressures.

-

Measure temperature drop across the coil (ideal: 15–20°F).

-

Run system for 30 minutes to ensure stable operation.

I learned quickly: never seal up access panels until you’ve confirmed proper performance.

10. 🧹 Post-Install Wrap-Up

Once everything ran smoothly, I:

-

Sealed all duct connections with mastic.

-

Insulated exposed suction lines.

-

Cleaned up debris.

-

Documented refrigerant pressures and temperatures for future service.

I also made a note to schedule my first coil cleaning after one season of use.

11. ⚠️ Common Mistakes to Avoid

Here are three mistakes I made—or almost made—that you should avoid:

-

Not leveling the coil: mine was off by just a hair, and the drain didn’t flow right until I fixed it.

-

Undersized drain lines: ¾ inch minimum is standard. Don’t try to get away with smaller.

-

Skipping duct sealing: a leaky coil cabinet can waste 10–20% of your system’s efficiency

12. ✅ Mike’s Final Takeaways

-

Installing a horizontal cased A-Coil is manageable for a skilled DIYer—but only up to the refrigerant side.

-

Built-in TXVs and factory casings make Goodman coils far easier to work with than older designs.

-

Pay close attention to airflow direction, drainage slope, and duct sealing.

-

Always pressure test, vacuum, and properly charge refrigerant with a licensed tech.

At the end of the day, the coil is the heart of your cooling system inside your home. Get the install right, and you’ll have efficient, reliable comfort for 10–15 years.

In the next topic we will know more about: Coil Sizing 101: Is 3.5–4 Tons Right for Your Home?