Installing a 4-ton air conditioner condenser is no small job. Whether you’re doing some of the prep yourself or hiring a pro, the process has plenty of moving parts—location, electrical, refrigerant lines, airflow, and testing.

I’m Mike Sanders, and I’ve helped with more than a few AC installs. Some went smoothly. Others… let’s just say I learned what not to do. In this guide, I’ll walk you through exactly what I learned about setting up a 4-ton Goodman R-32 condenser in 2025.

Even if you don’t plan to handle refrigerant yourself (and you shouldn’t—more on that later), this will help you understand the process, avoid mistakes, and talk to contractors like a pro.

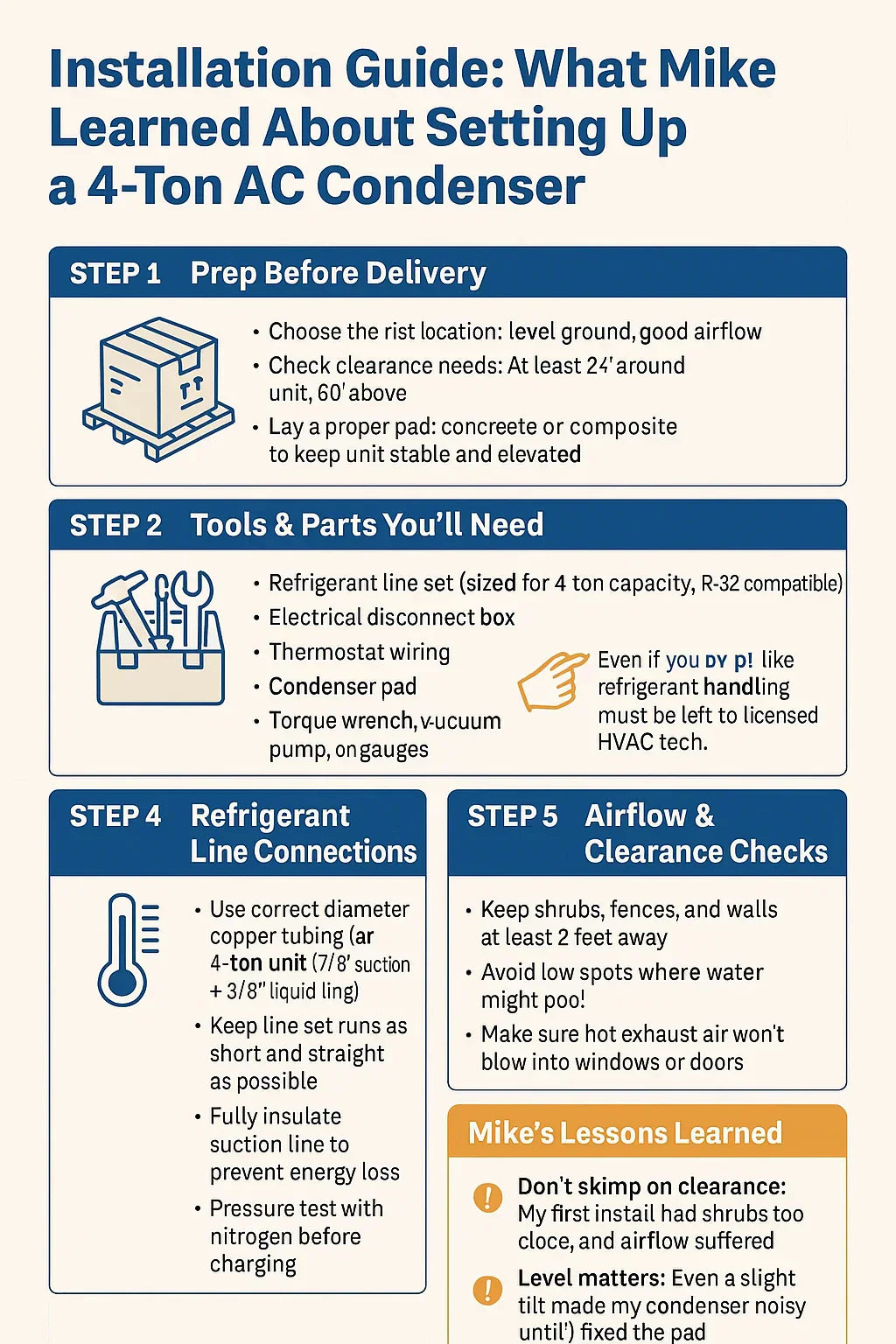

📦 Step 1: Prep Before Delivery

The most overlooked part of an AC installation happens before the unit even arrives: site prep. Get this wrong, and you’ll fight noise, airflow problems, and maintenance headaches for years.

🔍 Choosing the Right Location

Your condenser needs space to breathe. Pick a spot that:

-

Is close to your indoor air handler or furnace to minimize line set length.

-

Has at least 24 inches of clearance on all sides and 60 inches overhead.

-

Stays shaded when possible—shade improves efficiency.

-

Is away from dryer vents, kitchen exhausts, or anywhere hot air will blow toward it.

👉 If you tuck it behind shrubs or under a deck, you’re asking for poor airflow.

📖 Verified source: Energy Star – Air Conditioner Installation Tips.

🪨 Setting a Proper Pad

Your condenser can’t just sit in the dirt. A solid pad keeps it level and prevents sinking.

-

Concrete pads are durable but heavy.

-

Composite pads (like plastic or fiberglass blends) are lighter and absorb vibration.

The key is leveling. A tilt of even an inch can stress the compressor and make the unit noisy. I once installed a condenser without rechecking the pad after the ground settled. Two weeks later, it sounded like a jackhammer.

👉 Lesson learned: always check for level.

⚡ Prepping Electrical Service

A 4-ton condenser needs a dedicated 220V circuit with the correct breaker size (usually 30–50 amps depending on model).

-

Confirm wire gauge matches breaker size.

-

Install a weatherproof disconnect box within 6 feet of the condenser.

-

Double-check grounding—this is your system’s safety net.

📖 Verified source: NEC (National Electrical Code) HVAC requirements.

🧰 Step 2: Tools & Parts You’ll Need

Even if you’re just assisting or observing, it helps to know what tools and materials the job requires:

-

Refrigerant line set (R-32 compatible, usually 7/8" suction + 3/8" liquid line for a 4-ton system).

-

Condenser pad (concrete or composite).

-

Electrical disconnect box with weatherproof cover.

-

Thermostat wiring (18 AWG, 2–5 wires depending on setup).

-

Vacuum pump & manifold gauges (for the pro doing refrigerant work).

-

Nitrogen tank (for pressure testing).

-

Torque wrench & flaring tools (to ensure sealed line connections).

👉 Important: By law, only EPA 608-certified technicians can handle refrigerants like R-32. Homeowners can prep everything, but charging must be left to a pro.

📖 Verified source: EPA Section 608 Refrigerant Handling.

🔌 Step 3: Electrical Setup

Electricity is one of the most dangerous parts of an AC install, so never cut corners here.

-

Run a dedicated 220V line from your electrical panel to the outdoor unit.

-

Mount a disconnect switch on the wall within line of sight of the condenser. This lets a technician kill power during servicing.

-

Bond and ground everything properly.

I once saw a unit installed without a proper disconnect. The tech had to trip the breaker inside just to service it. Not only unsafe—it’s against code.

📖 Verified source: OSHA Electrical Safety Standards.

❄️ Step 4: Refrigerant Line Connections

This is the part that trips up most DIYers. Refrigerant lines must be installed perfectly—no leaks, no kinks, no shortcuts.

📏 Line Sizing

For a 4-ton system:

-

Suction line: 7/8" copper, insulated

-

Liquid line: 3/8" copper

Line length matters. Too long, and the system loses efficiency. Too short, and oil return suffers.

🔧 Installation Tips

-

Keep runs straight and avoid sharp bends.

-

Insulate the suction line from end to end.

-

Flare or braze connections carefully.

🧪 Leak Testing

-

Pressurize with nitrogen to check for leaks.

-

Use soap solution or electronic leak detectors.

📖 Verified source: HVAC School – Proper Line Set Installation.

🌬️ Step 5: Airflow & Clearance Checks

An AC condenser works by moving heat outside. If airflow is blocked, your efficiency plummets.

-

Keep 2–3 feet of space around the unit.

-

Don’t plant shrubs too close.

-

Avoid low spots where rainwater collects.

-

Position the fan discharge away from windows, doors, and living spaces.

I made the mistake of placing one too close to a fence once. The hot exhaust air looped back into the coil, making the system run hot all summer. A costly mistake that could’ve been avoided with 2 feet of extra clearance.

📖 Verified source: ASHRAE Fundamentals – Outdoor Equipment Placement.

⚖️ Step 6: Charging & Testing (Professional Required)

Here’s the part homeowners absolutely cannot DIY: charging the system with refrigerant.

🌀 Steps a Pro Will Take

-

Pull vacuum: Removes moisture and air from the lines.

-

Charge refrigerant: Add R-32 according to the unit’s label.

-

Check superheat & subcooling: Fine-tunes the refrigerant charge for efficiency.

-

Test pressures and amps: Ensures the system is running within spec.

If you try this yourself without certification, you’re breaking federal law and risking damage to a $5,000 system. Don’t do it.

📖 Verified source: Energy Vanguard – Refrigerant Charging Basics.

📝 Mike’s Lessons Learned

I’ve been around long enough to know that every installation teaches you something. Here are my biggest takeaways:

-

Clearance is everything. Don’t crowd the condenser with fences or shrubs.

-

Level matters. A tilted pad will lead to noise and stress on the compressor.

-

Hire a pro for refrigerant. I once thought topping off was “no big deal.” Wrong. A tiny leak ended up costing me hundreds.

-

Prep saves headaches. The better you plan pad location, electrical, and line runs, the smoother installation day goes.

✅ Homeowner Checklist Before Installing a 4-Ton AC Condenser

-

Location picked with proper clearance

-

Solid, level pad in place

-

Electrical service confirmed (breaker, wire gauge, disconnect)

-

Line set size and length verified

-

Pro scheduled for refrigerant charging & testing

If you can check off all these boxes, you’re ready to bring in the pros and get your new 4-ton system up and running smoothly.

📊 Cost Considerations

Installing a 4-ton condenser isn’t just about the equipment. Here’s the breakdown:

-

Condenser unit: $3,500–$5,000 (Goodman, Trane, Carrier ranges)

-

Installation labor: $3,000–$6,000 depending on complexity

-

Accessories: Pads, line sets, disconnects, thermostats ($500–$1,000)

-

Electrical work: $500–$1,500 if upgrades are needed

👉 Total installed cost: $7,000–$12,000 depending on brand and region.

🧾 The Bottom Line

Installing a 4-ton AC condenser takes planning and precision. Here’s the short version of what I learned:

-

Pick the right spot and prep it well.

-

Make sure your electrical setup is safe and up to code.

-

Use the correct line set sizes and keep them neat.

-

Leave refrigerant charging to licensed pros.

If you’re buying new in 2025, a Goodman R-32 condenser is one of the smartest choices—it’s efficient, future-proof, and easier to service than older R-410A systems.

At the end of the day, the right installation makes as much difference as the brand you choose. Get it right, and your system will keep you cool for the next 15–20 years.

In the next topic we will know more about: How Much Does a 4-Ton AC Cost in 2025? Equipment, Labor & Energy Use Explained