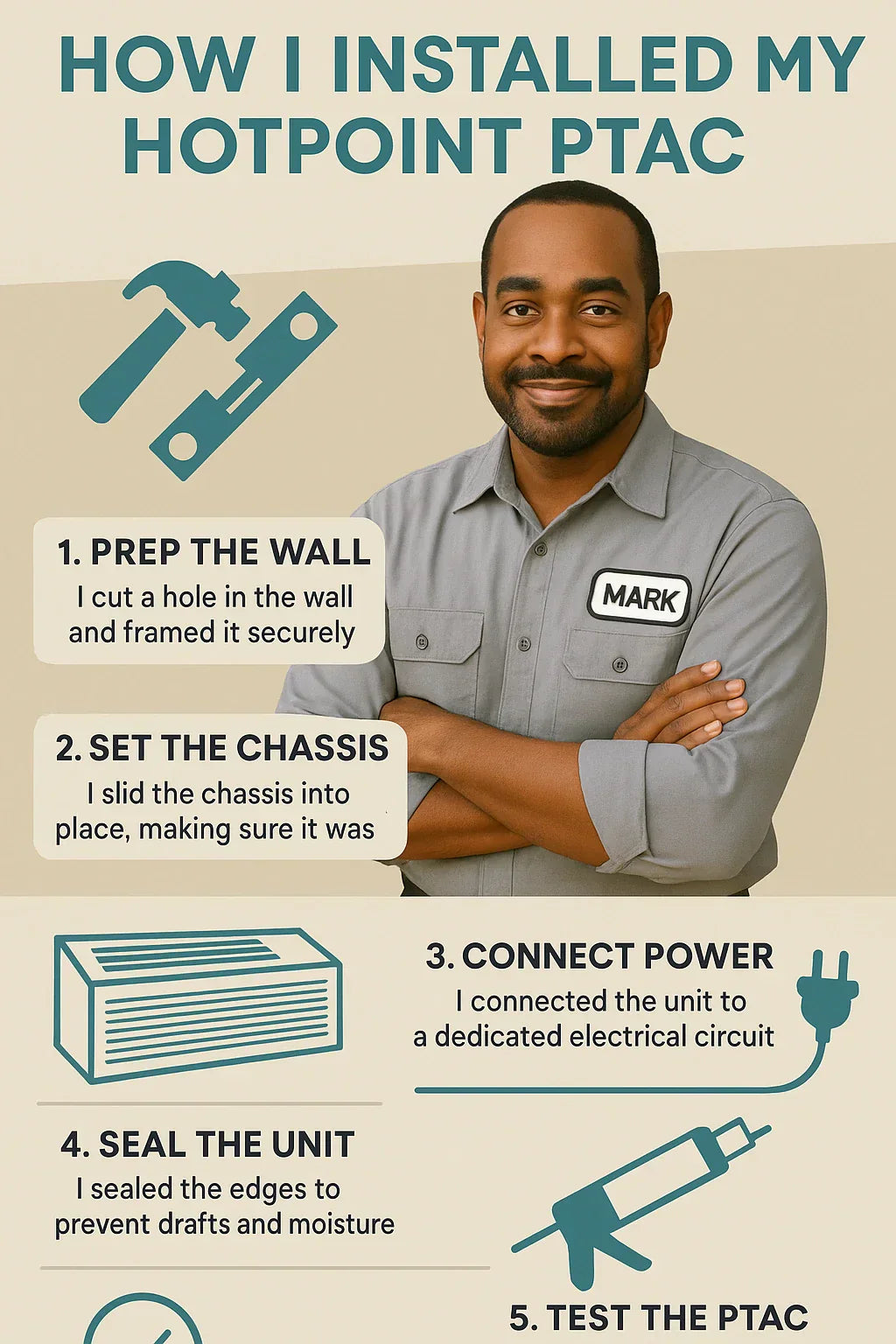

When I first bought my Hotpoint 15,000 BTU PTAC (Model AHES15D3XXA), I thought installation would be a quick weekend job. I’ve done plenty of DIY projects — but I quickly discovered there’s a lot more to setting up a PTAC than just sliding it into the wall and plugging it in.

This guide isn’t just about the technical steps. It’s about the real lessons I learned along the way: where I made mistakes, what worked well, and how you can save yourself time and money when installing a PTAC in your own space.

If you’re considering installing a Hotpoint (or any PTAC unit), this step-by-step guide will give you everything you need to know.

📦 Step 1: Unboxing & Preparing the Unit

The first thing I noticed when the PTAC arrived: it’s heavy. The 15,000 BTU unit weighs over 100 pounds. You’ll want a buddy to help move it around.

What’s in the box:

-

The PTAC unit itself.

-

Power cord (depending on plug kit ordered).

-

User manual and installation guide.

What’s not in the box:

-

Wall sleeve (required).

-

Exterior grille (strongly recommended).

-

Drain kit (optional but useful if your climate is humid).

-

Thermostat (optional — built-in controls work fine, but wall thermostats give more precision).

👉 Tip from me: Lay everything out before you start. I wasted 45 minutes digging through packaging just to realize the drain kit wasn’t included.

📖 Reference: Hotpoint PTAC installation details: GE Appliances PTAC Support

🧱 Step 2: Prepping the Wall Opening

PTACs use a standard wall opening: 42" wide × 16" high.

Since my basement already had an older unit, I thought the sleeve would be reusable. Wrong. The old sleeve had warped from years of condensation and wasn’t properly sealed. I ended up pulling it out.

Key checks before you begin:

-

Measure your wall cutout — confirm it’s the right size.

-

Make sure framing around the opening is solid.

-

Remove any old caulking or debris.

👉 Lesson learned: Don’t try to “make do” with an old sleeve. A new one costs about $150, and it makes all the difference in airflow and drainage.

📖 ENERGY STAR guidance on sealing and insulation: ENERGY STAR: Seal and Insulate

🔌 Step 3: Electrical Setup

This step is where most DIYers get tripped up. Unlike window ACs, PTACs require dedicated 208/230V circuits.

What I had to do:

-

Call an electrician to confirm my outlet was rated for 230V.

-

Choose the right amperage plug kit (my Hotpoint used a 20A).

-

Shut off power at the breaker before working near the wiring.

👉 My mistake: I thought I could just swap cords. But PTACs draw more power than standard appliances. If you don’t already have the right outlet, hire a pro.

📖 NEC safety guidelines for HVAC wiring: NFPA NEC Overview

🪟 Step 4: Installing the Wall Sleeve

The wall sleeve is basically the foundation of your PTAC setup. It supports the unit, manages drainage, and seals the wall opening.

Installation steps:

-

Slide the sleeve into the opening.

-

Ensure it slopes slightly outward (about ¼" drop) to let condensation drain.

-

Fasten it with screws into the wall framing.

-

Seal gaps around the sleeve with insulation or foam.

👉 My tip: I added foam insulation around the sleeve edges. It cut down on drafts and helped the unit run more efficiently.

📖 Sleeve installation details: Amana PTAC Sleeve Installation PDF

🌀 Step 5: Positioning the PTAC Unit

Now comes the heavy lifting. With the sleeve secure, it’s time to slide the unit in.

My experience:

-

I tried doing this alone — bad idea. The unit is bulky and easy to drop.

-

With two people, it slid into place smoothly.

-

Secure the unit with the included brackets/screws.

👉 Lesson learned: Don’t force it. If it’s not sliding in, check sleeve alignment. Mine was slightly tilted at first, and I had to re-level.

💧 Step 6: Drainage Setup

PTACs produce condensation. If you don’t manage it, you’ll get water leaks inside.

Options:

-

Internal evaporation: Uses heat from the condenser coil to evaporate most moisture.

-

External drain kit: Routes excess water outside — better for humid areas.

👉 My mistake: I skipped the drain kit initially. After the first humid day, I noticed water pooling inside. I had to reinstall with the kit.

📖 Drainage guide: ASHRAE HVAC Moisture Management

📲 Step 7: Thermostat & Controls

Hotpoint PTACs come with built-in electronic controls, but you can add a wired wall thermostat.

My setup:

-

Started with built-in controls.

-

Later upgraded to a wall thermostat for better accuracy.

👉 Advice: Start simple. If you’re happy with the built-in controls, you may not need to spend extra.

📖 Thermostat compatibility info: Energy.gov Smart Thermostats Guide

✅ Step 8: Testing the Unit

Before sealing everything up, test both cooling and heating.

My test checklist:

-

Run cooling for 20 minutes — check airflow and temperature drop.

-

Run heating for 10 minutes — confirm electric heat works.

-

Inspect for drips near the sleeve.

-

Listen for unusual rattles or hums.

👉 My first test showed a slight vibration noise. I hadn’t tightened the mounting screws enough. Quick fix.

🧹 Step 9: Sealing & Finishing Touches

With testing done, it’s time to weatherproof and finish.

Steps I took:

-

Caulked around the sleeve with exterior-grade sealant.

-

Installed the outdoor grille.

-

Cleaned up leftover insulation and foam.

👉 Trick: I used weatherproof silicone caulk — it keeps bugs and drafts out.

📖 Caulking techniques: EPA Weatherization Guide

🛠️ Troubleshooting Common Installation Issues

Here are some problems I ran into — and how I fixed them:

-

Unit won’t power on → Check outlet voltage and breaker.

-

Leaking water → Recheck sleeve slope and drain kit.

-

Excess noise → Confirm unit is level and screws are tight.

-

Weak airflow → Clean filters and ensure no blockage at grille.

👉 Biggest lesson: 90% of problems come from installation mistakes, not the PTAC itself.

💲 Cost Breakdown: DIY vs. Pro Installation

Here’s what I spent:

-

Hotpoint PTAC 15,000 BTU: $999

-

Wall sleeve: $160

-

Exterior grille: $80

-

Drain kit: $50

-

Foam/caulk/insulation: $40

-

Electrician (outlet check/install): $200

Total DIY cost: $1,529

Pro installation quote I got: $1,950–$2,200 (including labor).

👉 By doing it myself, I saved about $450–$600.

🎯 Final Thoughts: What Mark Learned

Installing my Hotpoint PTAC wasn’t as “plug-and-play” as I expected. But by the end of the project, I gained three big lessons:

-

Double-check measurements — your sleeve and wall opening have to be exact.

-

Don’t skip drainage — leaks are the #1 PTAC complaint, and they’re preventable.

-

Hire a pro for electrical — it’s worth the peace of mind.

Most importantly: the satisfaction of cooling and heating my basement suite with a system I installed myself was priceless.

If you’re willing to put in the work, you can absolutely DIY this — just learn from my mistakes and take your time.

In the next topic we will know more about: Do PTAC Units Like Hotpoint Qualify for Rebates or Tax Credits in 2025?