Introduction: The Big Decision

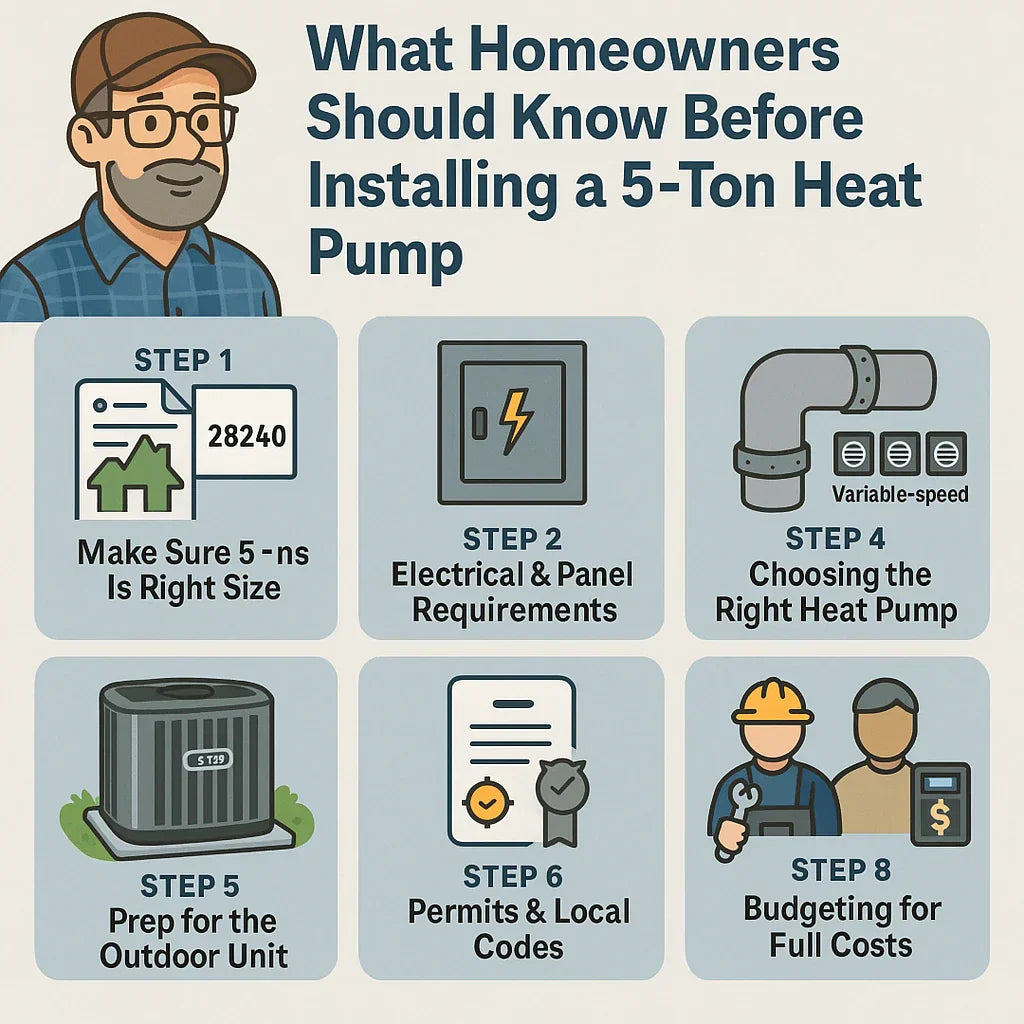

Installing a 5-ton heat pump is not a small undertaking. Whether you're upgrading an old HVAC system or building a new home, a unit of this size requires careful planning, site preparation, and system compatibility. For homeowners like Mike Sanders, who want long-term comfort, energy efficiency, and maximum ROI, skipping key steps before installation can lead to system inefficiencies, higher energy bills, or premature failure.

Mike's Tip: "Don’t rush into a big install just because your neighbor did. Your home is different. Make your plan first."

Step 1: Make Sure 5 Tons Is the Right Size

What "5 Tons" Really Means

A 5-ton heat pump moves 60,000 BTUs of heat per hour. It's typically suited for homes between 2,400 and 3,300 square feet, but square footage alone isn't enough to determine correct sizing.

Why You Need a Manual J Load Calculation

A Manual J load calculation considers:

-

Insulation levels

-

Number of windows

-

Type of windows

-

Orientation to the sun

-

Number of occupants

-

Home layout

-

Local climate

Hiring a licensed HVAC contractor to perform this analysis ensures your system isn’t undersized (leading to comfort issues) or oversized (causing short cycling and inefficiency).

Example: A 3,000 sq ft home in Phoenix may need a 5-ton unit, but the same size home in Seattle might only need 3.5 tons.

Learn More:

Step 2: Electrical & Panel Requirements

Voltage and Amperage Needs

Most 5-ton heat pumps require:

-

240V dedicated circuit

-

50–60 amp breaker

-

Disconnect box within line of sight

Is Your Panel Ready?

Check your main panel:

-

Is there enough capacity?

-

Is it rated for modern HVAC loads?

-

Will you need a subpanel?

Permitting for Electrical Work

Many jurisdictions require:

-

Electrical permit

-

Inspection of panel and new circuit

Step 3: Ductwork Evaluation

Duct Sizing & Design

Even the best heat pump can’t perform well with inadequate ductwork. Poor airflow reduces efficiency and puts strain on the compressor.

Ensure:

-

Properly sized supply and return ducts

-

Balanced airflow to each room

-

Insulated ducts in unconditioned spaces

Static Pressure Matters

A 5-ton unit generates more airflow. If your ducts are too small or restrictive, high static pressure can:

-

Reduce system efficiency

-

Cause blower failure

-

Make the system noisier

Mike's Tip: "Before installing any new unit, get a duct evaluation. Otherwise, it’s like putting a race engine in a lawnmower."

Learn More:

Step 4: Choosing the Right Heat Pump Type

Single-Stage

-

Full power every time it turns on

-

Lower upfront cost

-

Least efficient

Two-Stage

-

High and low settings

-

Better humidity control

-

More consistent indoor temps

Variable-Speed

-

Adjusts output in small increments

-

Maximum efficiency and comfort

-

May qualify for rebates and tax credits

Mike's Tip: "If you live in a humid or variable-climate area, two-stage or variable-speed is worth every penny."

Step 5: Site Prep for the Outdoor Unit

Space Requirements

Your outdoor unit needs:

-

At least 24–36 inches of clearance on all sides

-

Unobstructed airflow above and around

-

Minimum 5–8 feet from doors or windows (to reduce noise)

Base Requirements

-

Pour a concrete pad or use a prefab composite base

-

Must be level and secure

-

Keep clear of downspouts and puddling areas

Noise Considerations

A 5-ton unit is louder than smaller models. Avoid placing near:

-

Bedroom windows

-

Neighbor's fence

-

Living room walls

Learn More:

Step 6: Permits & Local Codes

What May Be Required:

-

HVAC replacement permit

-

Electrical permit (panel or circuit upgrade)

-

Inspection for refrigerant line sizing

-

Inspection of duct design and sealing

Failing to get permits:

-

Can result in code violations

-

May void manufacturer warranties

-

Could lead to denied homeowner insurance claims

Learn More:

Step 7: Professional Installation vs. DIY

What a Pro Handles:

-

Proper line set brazing and nitrogen purge

-

Refrigerant charge (EPA Section 608 certification required)

-

High-voltage wiring

-

System testing and commissioning

What You Can DIY (Maybe):

-

Install concrete pad

-

Run electrical conduit (with inspection)

-

Prep ductwork (under guidance)

Mike's Bottom Line: "This isn't a plug-and-play unit. Leave the big stuff to licensed pros."

Step 8: Budgeting for Full Costs

Breakdown of Estimated Costs:

| Item | Low Estimate | High Estimate |

|---|---|---|

| Heat Pump Unit | $8,000 | $12,000 |

| Installation Labor | $3,000 | $6,000 |

| Duct Modifications | $1,500 | $4,000 |

| Electrical Upgrades | $1,000 | $2,000 |

| Permits & Inspections | $300 | $1,000 |

| Tax Credits (IRA 2025) | -$2,000 | -$4,000 |

Learn More:

Conclusion: Set It Up Right the First Time

Installing a 5-ton heat pump is a major investment that affects your comfort and energy bills for the next 15–20 years. With the right prep, the right unit, and the right installer, you can enjoy consistent heating and cooling, lower energy costs, and peace of mind knowing your system is optimized for your home.

Mike’s Final Word: "Measure twice, install once. Don’t cut corners on a 5-ton setup. Your future self will thank you."

In the next topic we will know more about: Mike’s Troubleshooting Guide: What to Do If Your 5-Ton Heat Pump Isn’t Heating or Cooling Properly