Introduction: Why R‑32 Heat Pump Maintenance Matters

In 2025, R‑32 heat pumps have become the standard for homeowners across the U.S. and worldwide. They’re more efficient, eco‑friendly, and compliant with the EPA AIM Act that’s phasing down high‑GWP refrigerants like R‑410A. But here’s the catch: owning one isn’t enough—you’ve got to maintain it.

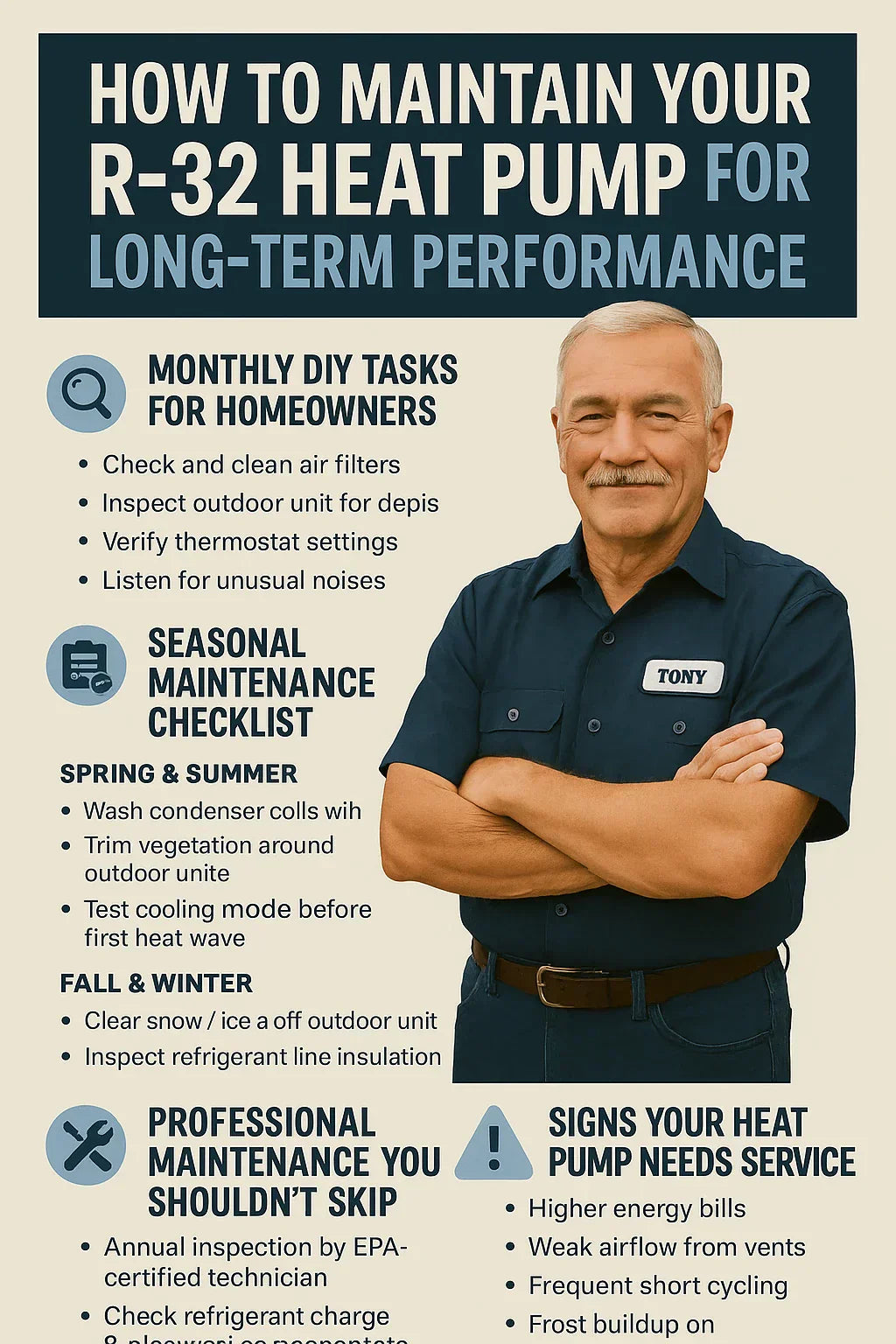

Tony’s learned the hard way that skipping regular care can turn a $7,000 system into a $3,000 headache when the compressor fails prematurely. A well‑maintained R‑32 heat pump can easily last 12–15 years, while a neglected one might fail in just 7–10 years.

This guide walks you through DIY monthly and seasonal tasks, when to call in a certified pro, and how to maximize efficiency and rebates while extending the life of your system.

🏡 2. Understanding R‑32 Heat Pumps

Before we talk about maintenance, let’s cover what makes R‑32 heat pumps different from older models.

🌍 Why R‑32 Instead of R‑410A?

-

Global Warming Potential (GWP):

-

R‑410A: ~2,088

-

R‑32: ~675 (70% lower impact)

-

-

Efficiency: Uses ~30% less refrigerant per ton of cooling

-

Safety: Classified as A2L (mildly flammable) by ASHRAE. Requires stricter installation and servicing standards.

🔧 Key Components You’ll Maintain

-

Outdoor Unit (Condenser/Compressor)

-

Indoor Unit (Air Handler or Coil)

-

Copper Line Set carrying refrigerant

-

Thermostat (often smart or programmable)

-

Drain Line for condensation removal

Tony’s tip: Know your system layout before trying any maintenance.

🧽 3. Monthly DIY Tasks for Homeowners

Simple monthly habits can keep your R‑32 heat pump healthy:

🌀 Replace or Clean Air Filters

-

Replace every 30–60 days (or clean if reusable).

-

A clogged filter reduces airflow and stresses the compressor.

🌿 Inspect Outdoor Unit

-

Clear leaves, grass clippings, or snow.

-

Maintain at least 2 feet clearance on all sides.

📡 Check Thermostat Settings

-

Verify heating/cooling mode matches the season.

-

For smart thermostats, check Wi‑Fi connectivity and firmware updates.

👂 Listen for Unusual Sounds

-

Grinding, hissing, or rattling can indicate mechanical or refrigerant issues.

Tony’s rule: “A $20 filter swap is cheaper than a $2,000 compressor repair.”

🍂 4. Seasonal Maintenance Checklist

🌸 Spring & Summer

-

Coil Cleaning: Hose off outdoor coils (gently—don’t use a pressure washer).

-

Vegetation Trim: Cut shrubs and branches within 2 feet of unit.

-

Cooling Test: Run A/C mode before the first heatwave.

-

Drain Line Check: Pour a cup of vinegar to clear algae buildup.

🍁 Fall & Winter

-

Snow & Ice Clearance: Gently clear off unit after storms.

-

Insulation Check: Inspect refrigerant line insulation; replace if worn.

-

Heating Test: Run heating mode before the first freeze.

-

Defrost Cycle Watch: Ensure frost melts properly when cycle kicks in.

Tony’s tip: “Do these before the season starts, not during the first heatwave or freeze.”

🔧 5. Professional Maintenance You Shouldn’t Skip

Even DIYers like Tony know some tasks are for EPA Section 608‑certified techs only.

🧰 Annual Pro Inspection Includes:

-

Checking refrigerant charge with A2L‑rated tools

-

Leak detection (required for R‑32)

-

Cleaning coils safely

-

Inspecting capacitors, contactors, and wiring

-

Testing reversing valve and defrost cycle

-

Ensuring UL 60335‑2‑40 compliance

🔥 Why It’s Critical

-

Keeps warranty valid

-

Prevents refrigerant leaks (which harm efficiency and safety)

-

Saves 10–25% on energy use annually (DOE)

Tony books his tune‑up every spring before cooling season starts.

📉 6. Signs Your Heat Pump Needs Immediate Service

Don’t wait for a breakdown. Call a pro if you notice:

-

📈 Sudden energy bill spikes

-

🌬️ Weak or inconsistent airflow

-

🔄 Frequent short cycling or breaker trips

-

❄️ Frost buildup outside normal defrost cycles

-

🔊 Grinding, screeching, or hissing noises

-

👃 Burning, chemical, or musty odors

🧰 7. Tools & Supplies for DIY Care

You don’t need a pro’s full toolkit, but having the right supplies helps:

-

Soft brush & hose – clean coils

-

Replacement filters – buy in packs

-

Thermometer – measure supply vs return air (should differ by 15–20°F)

-

Leaf blower/vacuum – clear debris

-

Fin comb – straighten bent coil fins

⚠️ Never attempt refrigerant handling—that’s pro‑only.

🌍 8. How Proper Maintenance Extends Life & Efficiency

-

Well‑maintained lifespan: 12–15 years

-

Neglected lifespan: 7–10 years

-

Compressor replacement cost: $2,000–$3,000

-

Annual energy savings: $300–$800

Tony’s philosophy: “Spend $200 a year on maintenance, not $3,000 on repairs.”

💡 9. Tony’s Long‑Term Maintenance Strategy

Here’s the checklist Tony follows at home:

-

Change filters every 30–60 days

-

Clear outdoor unit monthly

-

Check thermostat monthly

-

Schedule pro tune‑up once a year

-

Track electric bills for sudden changes

-

Keep a $300/year maintenance budget

Tony also keeps a small logbook: noting filter changes, energy use, and pro visits.

🛠️ 10. Extra Care Tips for R‑32 Heat Pumps

⚡ Electrical Safety

-

Ensure outdoor disconnect box is weather‑sealed.

-

Don’t overload circuits with other high‑draw appliances.

❄️ Cold Climate Care

-

Add a snow guard or awning (without blocking airflow).

-

Keep a shovel handy for clearing after heavy snow.

🌿 Indoor Air Quality

-

Pair your system with a smart thermostat that tracks humidity.

-

Consider a UV light or dehumidifier if you live in a humid climate.

🏁 Final Thoughts

Tony’s bottom line: Maintaining your R‑32 heat pump isn’t optional—it’s the key to long‑term comfort and savings.

-

✅ Do your monthly and seasonal checks yourself.

-

✅ Hire a certified pro annually for refrigerant, electrical, and safety inspections.

-

✅ Budget small now to avoid big surprises later.

By combining DIY discipline with pro expertise, you’ll keep your R‑32 heat pump running efficiently, safe, and reliable for well over a decade.

In the next topic we will know more about: Single-Stage vs. Two-Stage R‑32 Heat Pumps: Which Should You Choose for a 2‑Ton System?