How to Maintain Your Goodman System for Peak Performance: Filters, Coils, Tune-Ups & Seasonal Checks

You can buy the best Goodman AC, heat pump, or furnace out there — but if you don’t maintain it, you’re throwing efficiency, comfort, and lifespan straight out the window.

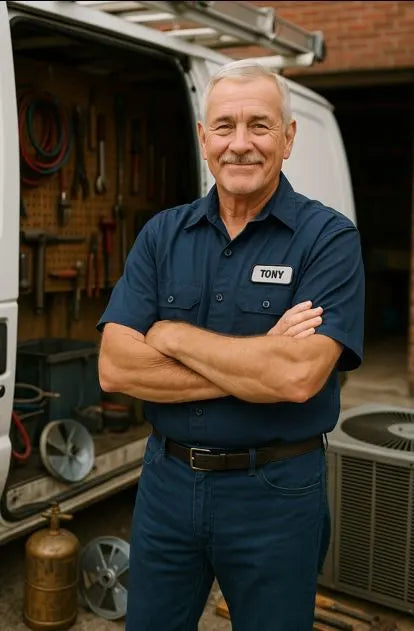

Tony has serviced thousands of systems, and he’ll tell you the same thing every time:

“Goodman equipment is built to last — but only if you keep it clean and give it the airflow it was designed for.”

This guide shows you exactly how to maintain your Goodman system the right way — not the “spray a garden hose at it twice a year” way.

Filters, coils, blowers, drains, seasonal prep… if Tony checks it on real service calls, it’s in this guide.

Let’s dive in and keep your Goodman system running like a champ.

1. Filters: The #1 Maintenance Step You Should NEVER Skip

Dirty filters are the cause of:

-

weak airflow

-

frozen coils

-

high energy bills

-

blower failure

-

poor cooling

-

overheated furnaces

Tony’s rule is simple:

1-inch filters: replace every 30–45 days

4-inch filters: replace every 3–6 months

Media/HEPA filters: follow manufacturer schedule

If you can’t see light through the filter, your Goodman system can’t breathe.

(Reference: Air Distribution and Duct Sizing Reference)

2. Cleaning the Indoor Coil: The Cooling Workhorse

Your evaporator coil is where most of the cooling actually happens.

If it’s dirty, it loses 20–40% capacity instantly.

Tony cleans coils when he sees:

-

dust buildup

-

pet hair

-

mold or mildew

-

restricted airflow

-

warm supply temps

-

increased humidity

A clean coil:

-

cools faster

-

removes humidity better

-

lowers energy use

-

protects your compressor

Tony recommends coil cleaning every 18–24 months — sooner for pets, smokers, or dusty homes.

(Reference: Room AC Vibration and Sound Diagnostics Manual)

3. Cleaning the Outdoor Coil: Boost Your Goodman’s Efficiency 10–20%

Your condenser coil sits outside catching:

-

dirt

-

pollen

-

cottonwood

-

leaves

-

grass

-

dust

A clogged outdoor coil makes refrigerant pressures skyrocket — and that destroys compressors.

Tony’s outdoor coil maintenance:

-

rinse from inside-out (not outside-in)

-

straighten bent fins

-

clear vegetation

-

maintain 18–24 inches of clearance

-

avoid pressure washers

A clean Goodman condenser is a happy condenser.

4. Drain Line Maintenance: The Most Common Reason ACs Fail in Summer

Heat + humidity = gallons of water dripping off your indoor coil daily.

If the drain line clogs, the system shuts down or overflows.

Tony’s maintenance steps:

-

flush the drain with hot water + vinegar

-

clear the trap

-

test float switches

-

check secondary drain pan

-

ensure proper slope

How often?

Every season in humid climates

Twice a year everywhere else

Don’t wait for water stains to show up on your ceiling.

(Reference: Home Insulation and Envelope Performance Manual)

5. Blower Motor & Wheel: The Heart of Your Goodman Airflow

Your blower determines airflow — and airflow determines comfort.

A dirty blower wheel loses up to 30% of its capacity.

Tony checks:

-

wheel cleanliness

-

motor bearings

-

blower balance

-

ECM operation

-

blower speed settings

He cleans the wheel every 2–3 years and inspects annually.

If the blower is weak, your entire Goodman system suffers.

(Reference: HVAC Noise and Acoustics Guidelines)

6. Check Electrical Components: Small Parts That Save Big Money

Goodman systems are reliable, but electrical parts wear over time.

Tony inspects:

-

contactors

-

capacitors

-

relays

-

wiring connections

-

furnace control boards

-

thermostat wiring

These parts prevent:

-

hard starts

-

overheating

-

high amp draw

-

intermittent cooling

Electrical checks = cheap prevention.

7. Refrigerant Levels: Don’t Guess — Let a Tech Measure

R-410A and R-32 systems require precise refrigerant charge.

Low refrigerant means:

-

leaks

-

poor cooling

-

frozen coils

-

compressor overload

High refrigerant means:

-

skyrocketing pressures

-

loud operation

-

wasted energy

-

refrigerant floodback

Tony checks:

-

superheat

-

subcooling

-

suction pressure

-

liquid pressure

-

coil temperature

Never let anyone “top off” refrigerant without diagnosing the actual problem.

(Reference: Equipment Matching and System Compatibility Guidelines)

8. Thermostat Calibration: The Most Underestimated Maintenance Task

Your thermostat decides:

-

cycle length

-

temperature accuracy

-

comfort levels

-

humidity control

Tony recalibrates and tests:

-

temperature readings

-

cycle timing

-

anticipator settings (older stats)

-

Wi-Fi control logic

-

staging behavior (two-stage systems)

A poorly calibrated thermostat can waste 10–15% of cooling efficiency.

9. Ductwork Inspection: Where 50% of Comfort Problems Start

Goodman systems are airflow-driven.

If your ducts can’t support 400 CFM per ton, your system is already handicapped.

Tony checks for:

-

leaking joints

-

crushed flex duct

-

undersized returns

-

long, unsupported runs

-

unsealed plenums

-

insulation gaps

Fixing ductwork can improve airflow by 20–40%.

10. Seasonal Tune-Up Checklist (Tony’s Personal System)

Tony runs this checklist on every Goodman tune-up:

SPRING

-

change filter

-

clean outdoor coil

-

flush drain line

-

check blower wheel

-

test refrigerant levels

-

measure static pressure

-

calibrate thermostat

SUMMER

-

rinse condenser

-

verify drain operation

-

check temperature split

-

inspect electrical connections

FALL

-

replace filter

-

clean furnace burners

-

vacuum heat exchanger

-

test ignitor

-

check gas pressure

-

inspect flue

WINTER

-

monitor heat cycles

-

listen for blower noise

-

verify flame quality

-

check CO detectors

Year-round maintenance keeps your Goodman system from ever “falling behind.”

11. How Often Should You Schedule Professional Maintenance?

Tony’s rule:

✔ AC/Heat Pump Only Homes: Twice a year

-

spring cooling tune-up

-

fall heating check

✔ Furnace + AC Homes: Twice a year

-

spring AC tune-up

-

fall furnace tune-up

✔ Harsh climates: Three times a year

Goodman systems don’t require excessive service — just consistent, smart service.

12. Tony’s Final Verdict: Maintenance Makes or Breaks Goodman Performance

Goodman systems offer:

-

excellent reliability

-

great efficiency

-

strong airflow

-

durable components

-

long lifespans

But they only deliver peak performance if homeowners follow Tony’s four rules:

✔ Keep the filter clean

✔ Keep the coils clean

✔ Keep the drain clear

✔ Get a real tune-up

Do that, and your Goodman system will run quieter, cooler, and more efficiently than you ever expected.

Tony will help us with the troubleshooting checklist in the next blog.