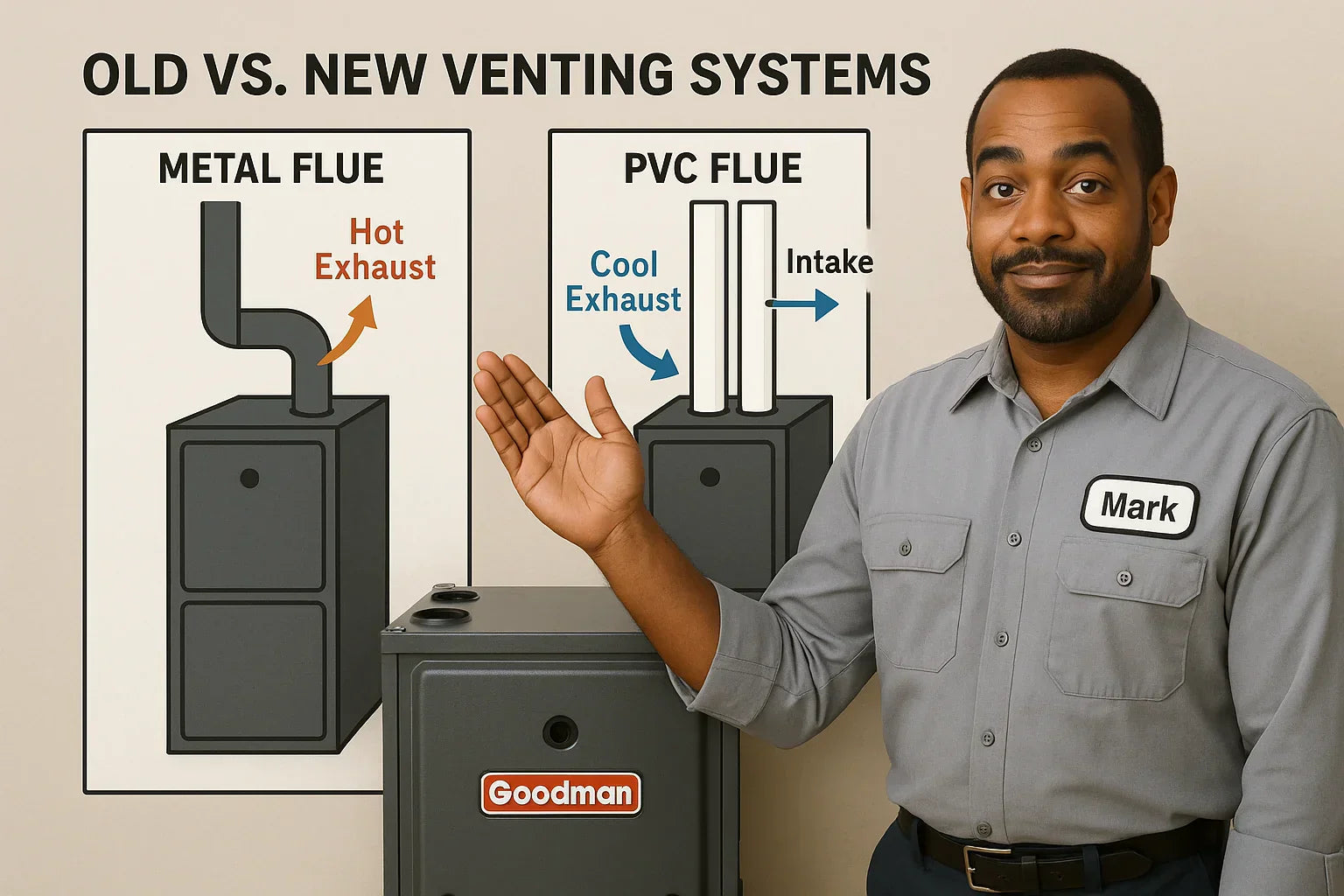

When I replaced my old gas furnace a few years ago, I noticed something interesting right away: the old metal chimney flue was gone. In its place were two white PVC pipes running through the side wall of my house.

I had installed a Goodman 96% AFUE 120,000 BTU Two-Stage Variable-Speed Gas Furnace (Model GRVT961205DN), and my installer explained that it didn’t need a metal vent anymore.

As a hands-on homeowner, that got me curious. Why the switch? What makes PVC venting safe for high-efficiency furnaces when older ones needed metal? And how does it all work together?

If you’ve wondered the same, this article breaks down everything you need to know about furnace venting systems — how they’ve evolved, how Goodman uses them for efficiency, and how to keep them running safely year after year.

💡 Why Furnace Venting Matters More Than You Think

Every gas furnace, whether it’s an old 80% model or a new 96% high-efficiency unit, creates combustion gases when burning fuel. These gases include:

-

Carbon dioxide (CO₂)

-

Water vapor

-

Nitrogen oxides

-

Trace amounts of carbon monoxide (CO)

Those byproducts must be safely vented out of the home — otherwise, you risk carbon monoxide buildup and reduced indoor air quality.

Venting also affects:

-

Efficiency: How much heat your system keeps before exhaust leaves.

-

Installation cost: Different vent types have different materials and routes.

-

Durability: Poor venting can corrode or damage your furnace.

💬 “When I upgraded to my Goodman 96% furnace, I noticed those two PVC pipes right away. My installer told me they were the secret to high efficiency — and safer too.” — Mark

According to Energy.gov, modern condensing furnaces use advanced venting systems to capture and reuse heat that older models simply wasted up the chimney.

🔥 The Basics — How Furnace Exhaust Works

At its core, a gas furnace is a combustion machine. It burns fuel to create heat, which is transferred to air through the heat exchanger. But burning fuel also creates exhaust gases that must be expelled safely.

Here’s the process simplified:

-

Combustion — The gas burners ignite inside the combustion chamber.

-

Heat Exchange — Heat transfers to the indoor air, but the exhaust gases stay isolated.

-

Exhaust Venting — The flue system carries those gases outdoors.

The type of vent your furnace uses depends entirely on how efficiently it burns fuel — measured by AFUE (Annual Fuel Utilization Efficiency).

| Furnace Type | AFUE | Vent Material |

|---|---|---|

| Standard Efficiency | ~80% | Metal flue (hot exhaust) |

| High Efficiency | 90–98% | PVC flue (cool exhaust) |

Reference: HVAC School – Furnace Draft and Venting Principles

🧱 Metal Flue Systems — Traditional, Durable, and Hot

Before high-efficiency furnaces came along, every home used metal venting, typically made of galvanized steel or aluminum. These systems rely on what’s called natural draft — the principle that hot air rises.

When exhaust gases exit the furnace at 300–400°F, they naturally flow upward through a vertical chimney and out the roof.

🔩 How It Works:

-

Exhaust gases rise naturally due to buoyancy.

-

The flue pipe directs them vertically out of the house.

-

The chimney remains warm enough to maintain the draft.

✅ Advantages:

-

Proven and reliable over decades.

-

Requires no vent fan or condensate drain.

-

Simple design for standard-efficiency units.

⚠️ Disadvantages:

-

Wastes energy — much of the heat escapes with exhaust.

-

Requires a vertical vent path and chimney liner.

-

Prone to corrosion and backdrafting if improperly installed.

💬 “My old metal flue worked, but you could feel the heat radiating out of it. That’s energy literally going up the chimney.” — Mark

Reference: International Code Council – Metal Venting Requirements

🧰 PVC Venting Systems — The Modern Standard for High Efficiency

When furnace technology evolved past 90% AFUE, the old metal flues couldn’t handle the new exhaust temperatures.

That’s because high-efficiency systems extract so much heat from combustion gases that the exhaust leaving the furnace is barely warm — often around 100°F.

These cooler gases don’t rise on their own, so manufacturers like Goodman use induced draft blowers and PVC venting to push the gases safely outdoors.

🔧 How It Works:

-

A small fan draws in combustion air and pushes out exhaust gases.

-

Cool exhaust travels through PVC or CPVC pipes.

-

Condensation forms and drains through a PVC condensate line.

-

The system uses two pipes:

-

Intake: Pulls fresh air in from outside.

-

Exhaust: Vents combustion gases outdoors.

-

✅ Advantages:

-

Cooler exhaust = safer venting.

-

Flexible routing (horizontal or vertical).

-

No chimney required.

-

Resistant to corrosion and condensation.

-

Quieter, sealed combustion.

⚠️ Disadvantages:

-

Must be sloped correctly to drain condensate.

-

Requires occasional inspection for frost or blockage.

-

Uses PVC cement and joints that need proper installation.

🧊 Why High-Efficiency Furnaces Use PVC Instead of Metal

To understand why Goodman uses PVC venting on models like the GRVT961205DN, you need to look at how condensing furnaces work.

In an older 80% furnace, exhaust gases leave hot enough to escape naturally through a chimney. But in a 96% AFUE furnace, nearly all of that heat is captured inside a secondary heat exchanger before the gases exit.

That extra heat extraction cools the exhaust — causing water vapor in the gases to condense into liquid water, hence the term condensing furnace.

This condensate is acidic and would quickly corrode metal pipes. PVC, however, is immune to this kind of corrosion.

💬 “My Goodman’s exhaust is barely warm to the touch — that’s how I know it’s working efficiently.” — Mark

⚙️ Inside a Goodman PVC Venting System

Goodman’s venting design for the GRVT961205DN is a perfect example of modern furnace engineering.

🧩 Main Components:

-

Two PVC Pipes (2”–3”) — One for intake air, one for exhaust.

-

Condensate Drain Line — Channels condensed water to a floor drain or pump.

-

Induced Draft Fan — Moves combustion air through the system.

-

Pressure Switches — Monitor vent pressure for safe operation.

-

Termination Caps — Keep debris and snow out of the pipes.

-

PVC Cement and Fittings — Ensure airtight, watertight joints.

📈 Installation Tip:

PVC pipes should slope ¼ inch per foot back toward the furnace to allow condensate to drain properly — otherwise, water can collect and block airflow.

Reference: NFPA 54 – National Fuel Gas Code

🧯 Safety Benefits of PVC Venting

PVC venting isn’t just about efficiency — it’s about safety.

-

Sealed Combustion: Air for combustion is drawn from outdoors, not from your living space. This prevents negative pressure and backdrafting.

-

Direct Exhaust: Combustion gases are fully contained and expelled directly outdoors.

-

CO Prevention: The sealed system drastically reduces carbon monoxide risks.

-

Automatic Safety Checks: Pressure sensors shut down the furnace if venting is blocked.

💬 “When you’re talking about gas appliances, safety isn’t optional. PVC venting makes sure the furnace breathes and exhales properly — no shortcuts.” — Mark

Reference: National Fire Protection Association – Combustion Air and Vent Safety

🧩 PVC vs. Metal Venting — The Key Differences

| Feature | Metal Flue (80% Furnace) | PVC Flue (96% Furnace) |

|---|---|---|

| Efficiency | ~80% | 90–96% |

| Exhaust Temperature | 300–400°F | 100–120°F |

| Draft Type | Natural (rising hot air) | Forced (blower fan) |

| Vent Direction | Vertical only | Horizontal or vertical |

| Materials | Galvanized steel | PVC or CPVC |

| Corrosion Resistance | Low | High |

| Safety | Moderate | Excellent |

| Energy Waste | High | Minimal |

The difference is clear: PVC venting represents modern heating technology — safer, cleaner, and more adaptable to tight home designs.

🧼 Maintaining a PVC Venting System

Just because it’s low-maintenance doesn’t mean “no maintenance.” Keeping your PVC vent clear and clean is key to maintaining Goodman’s efficiency.

✅ Mark’s Maintenance Checklist:

-

Monthly: Check outdoor intake and exhaust for snow, frost, or debris.

-

Twice a year: Flush condensate line with a vinegar and warm water mix.

-

Annually: Inspect joints and fittings for discoloration or corrosion.

-

Every 3–5 years: Have a pro clean the entire vent run and inspect slope.

💬 “I check my vent pipes every time I shovel snow — it takes 30 seconds and could prevent a shutdown.” — Mark

🌬️ Common PVC Venting Problems (and How to Prevent Them)

Even the best systems can run into issues if installed or maintained improperly. Here are the most common ones — and how to fix or avoid them:

-

Frost or Ice Buildup:

-

Install vent hoods and keep area clear of snow.

-

Ensure vent termination is at least 12 inches above grade.

-

-

Improper Slope:

-

Reposition vent lines to ensure condensate flows back to the furnace.

-

-

Condensate Freezing:

-

Insulate exposed sections or reroute indoors.

-

-

Improper Glue or Fittings:

-

Use PVC cement rated for flue gas temperatures.

-

-

Blocked Terminations:

-

Keep vents at least 3 feet from doors, windows, or shrubs.

-

🧮 Cost Comparison: Metal vs. PVC Venting

| Component | Metal Flue | PVC Vent |

|---|---|---|

| Materials | $300–$600 | $150–$400 |

| Labor | $800–$1,200 | $1,000–$1,500 |

| Total Installed Cost | $1,100–$1,800 | $1,200–$1,900 |

| Lifespan | 15–20 years | 20–25 years |

PVC venting may cost about the same upfront, but the long-term savings from improved furnace efficiency easily offset the difference.

Reference: Furnace Vent Installation Costs

🔧 Retrofitting — Can You Replace Metal with PVC?

Yes, absolutely — when upgrading from an 80% furnace to a high-efficiency model like the Goodman GRVT961205DN.

However, retrofitting requires a few key steps:

-

Seal the old chimney vent. It won’t be used for exhaust anymore.

-

Install PVC venting through an exterior wall or ceiling.

-

Add a condensate drain line or pump for water management.

-

Ensure proper vent clearances from windows, decks, or soffits.

💬 “When I upgraded my furnace, the installer simply ran two white pipes out the basement wall — no more leaky chimney. It looked clean and modern.” — Mark

🧭 Local Codes and Permitting Requirements

Before any venting work begins, your installer must follow national and local building codes.

Key standards include:

-

NFPA 54 (National Fuel Gas Code) for combustion air, vent materials, and slope.

-

Clearances:

-

Terminations at least 12 inches above ground.

-

3 feet from doors and windows.

-

¼ inch per foot slope back toward the furnace.

-

-

Permits: Required for furnace replacement or venting modifications.

Following these ensures both performance and warranty compliance.

🧠 Frequently Asked Questions

1. Can PVC venting melt or deform?

No. The exhaust temperature in a 96% furnace rarely exceeds 120°F, well below PVC’s heat tolerance (140°F).

2. Do I need two PVC pipes?

Yes, most high-efficiency furnaces use dual-pipe systems — one for fresh air intake, one for exhaust.

3. Can I vent through the roof instead of the wall?

Yes, vertical PVC venting is acceptable if properly sloped and sealed.

4. What if I have a shared water heater flue?

High-efficiency furnaces vent separately — your old metal flue may still serve the water heater.

5. Do PVC pipes need insulation?

Only if they run through unheated spaces to prevent condensation freezing.

💬 Mark’s Final Take — Why PVC Venting Is the Future

“Upgrading to a Goodman 96% furnace taught me that venting isn’t just about getting exhaust out — it’s about getting efficiency in. PVC venting is cleaner, safer, and smarter. It’s one of those upgrades you don’t notice until you realize how much quieter and more comfortable your home feels.”

PVC venting represents the evolution of heating technology — transforming how furnaces operate while making homes safer and more energy-efficient.

If you’re planning to replace an older furnace, take a close look at the Goodman GRVT961205DN. Those two PVC pipes are more than just plumbing — they’re the future of comfort done right.

✅ Final Word

Furnace venting might seem like a small detail, but it’s one of the biggest differences between old and new heating technology.

With PVC venting, high-efficiency systems like the Goodman 96% AFUE GRVT961205DN deliver more heat, greater safety, and lower energy costs — all in a cleaner, quieter package.

If you see two white pipes coming out of your home this winter, smile — your furnace is working smarter, not harder.

In the next topic we will know more about: Energy Rebates and Tax Credits for 96% AFUE Furnaces in 2025