Before you ever flip a breaker, open a gas valve, or power a system for the first time, there’s a moment that defines whether you’re a professional installer or just someone who got the equipment in place.

That moment is pre-start.

Pre-start safety and compliance aren’t about red tape—they’re about protecting lives, protecting equipment, and protecting your future business. For first-time installers, this is where most mistakes happen… and where most expensive lessons begin.

This guide walks you through what to verify before startup, why it matters, and how to do it the right way the first time.

Goodman 68,240 BTU 20 kW Electric Furnace with 2,000 CFM Airflow - MBVK20DP1X00, HKTAD201

🚦 Why Pre-Start Safety Is Non-Negotiable

Startup failures don’t usually come from “bad equipment.” They come from missed steps before power is applied.

Pre-start checks prevent:

-

Electrical fires

-

Equipment damage

-

Code violations

-

Failed inspections

-

Warranty denials

-

Lawsuits you don’t want to imagine

If you’re new, understand this:

The system is most dangerous before it ever runs.

🧠 The Installer Mindset That Prevents Accidents

Good installers don’t rush.

Great installers pause.

Before startup, your job is not to impress anyone with speed—it’s to verify, confirm, and document.

That mindset alone will save you from 80% of beginner mistakes.

🔌 Electrical Safety: The Top Priority

Electricity doesn’t care if you’re new.

⚡ What Must Be Verified Before Power-Up

-

Correct voltage at disconnect

-

Proper breaker size

-

Correct wire gauge

-

Solid grounding and bonding

-

No exposed conductors

The National Electrical Code (NEC) sets minimum safety standards for a reason:

👉 https://www.nfpa.org/education-and-research/electrical/understanding-nfpa-70-national-electrical-code

Never assume power is correct—measure it.

🔩 Torque & Connections: Small Details, Big Consequences

Loose electrical connections cause:

-

Overheating

-

Arcing

-

Burnt terminals

-

Hidden fire risks

Before startup:

-

Torque lugs to manufacturer specs

-

Inspect factory connections

-

Recheck aluminum wiring

One loose lug can end a business.

🌬️ Airflow & Ventilation Compliance

Airflow isn’t just about comfort—it’s a safety requirement.

🔄 What You Must Confirm

-

Blower speed matches system design

-

Filters are installed

-

Supply and return paths are unobstructed

-

Ductwork isn’t crushed or leaking badly

ASHRAE fundamentals explain why airflow is critical to system safety and performance:

👉 https://www.ashrae.org/technical-resources

Poor airflow causes:

-

Overheating

-

Limit trips

-

Equipment failure

-

Noise complaints

🔥 Combustion & Venting (If Applicable)

If you’re installing gas or combustion-based equipment, pre-start compliance becomes even more critical.

🧯 Required Checks

-

Correct vent type and size

-

Proper slope and termination

-

Combustion air availability

-

No shared vent conflicts

Local codes vary, but combustion safety never does.

If you’re unsure—stop and verify.

📋 Code Compliance: Know Before You Install

Compliance isn’t optional. It’s part of the job.

🏛️ What Inspectors Expect

-

Equipment installed per manufacturer instructions

-

Clearances maintained

-

Proper labeling

-

Accessible service space

-

Permits pulled when required

Manufacturers’ instructions are legally enforceable:

👉 https://www.goodmanmfg.com/resources

Ignoring them can void warranties instantly.

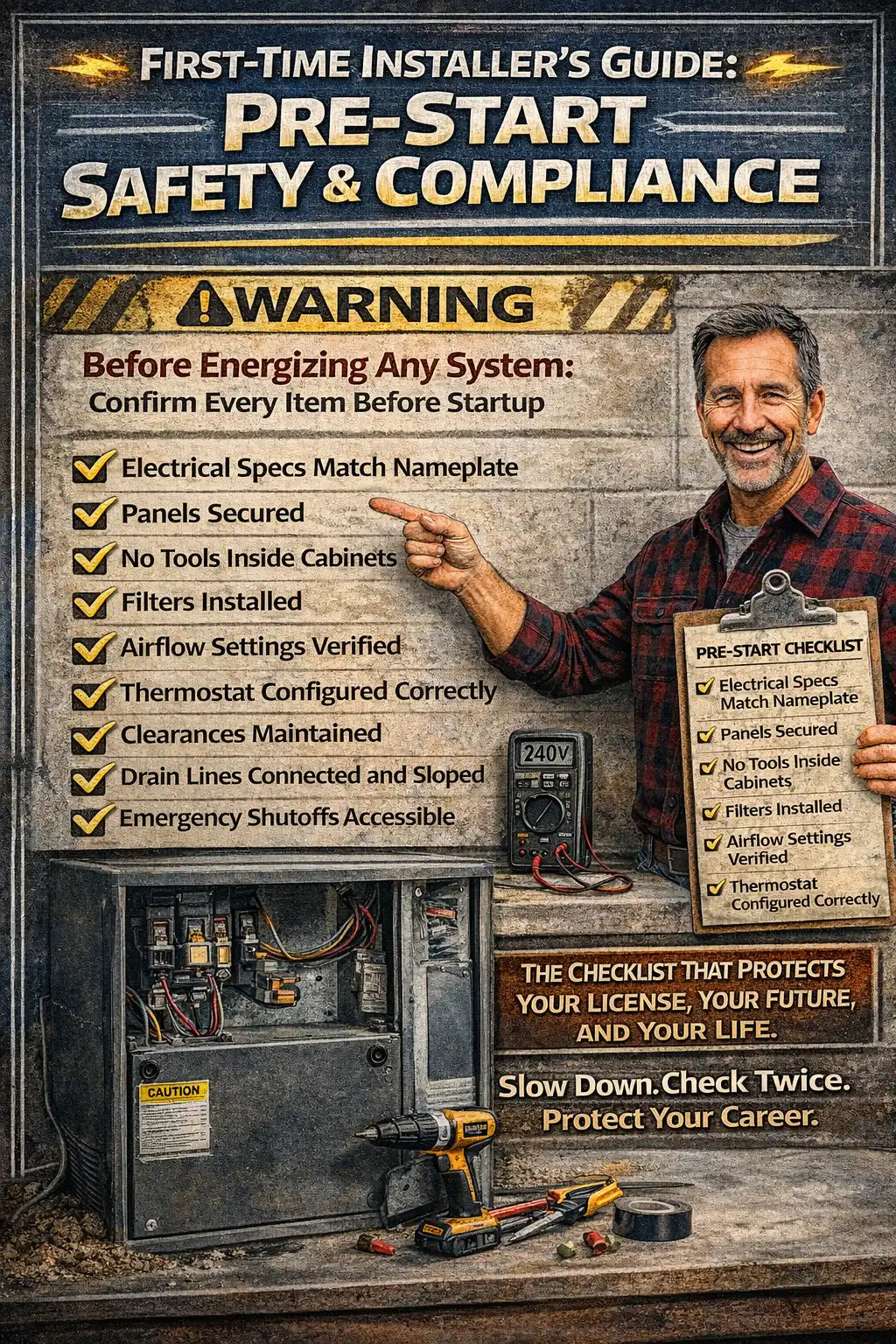

🧪 Pre-Start Safety Checklist (Use This Every Time)

Before startup, confirm:

-

✅ Electrical specs match nameplate

-

✅ Panels secured

-

✅ No tools inside cabinets

-

✅ Filters installed

-

✅ Airflow settings verified

-

✅ Thermostat configured correctly

-

✅ Clearances maintained

-

✅ Drain lines connected and sloped

-

✅ Emergency shutoffs accessible

If you skip the checklist, you’re gambling.

📸 Documentation: Your Silent Protection

Take photos of:

-

Electrical connections

-

Breaker labeling

-

Venting

-

Airflow settings

-

Final install condition

Why?

-

Inspection support

-

Warranty defense

-

Customer disputes

-

Training reference

AHRI emphasizes proper installation documentation for performance and warranty integrity:

👉 https://www.ahrinet.org

🧠 Communicating Safety to the Customer

Don’t just install—educate.

Explain:

-

Why startup takes time

-

What smells or sounds are normal

-

When to call you

-

When not to call you

Educated customers create fewer emergencies.

Energy.gov reinforces homeowner awareness as part of safe system operation:

👉 https://www.energy.gov/energysaver/energy-saver

🚫 Common Pre-Start Mistakes First-Timers Make

❌ Rushing to Finish

Speed creates mistakes. Mistakes create callbacks.

❌ Assuming Factory Settings Are Correct

Always verify.

❌ Skipping Documentation

If it’s not documented, it didn’t happen.

🧱 How Pre-Start Discipline Builds Long-Term Success

Pre-start safety:

-

Builds inspector trust

-

Reduces callbacks

-

Improves reviews

-

Protects your license

-

Protects your future

It’s not just about today’s job—it’s about every job after it.

🧠 Mike’s Final Word

If you’re new, hear this clearly:

You don’t prove professionalism by how fast you start a system.

You prove it by how carefully you prepare it.

Pre-start safety and compliance aren’t optional steps—they’re the foundation of a career that lasts.

Slow down.

Check twice.

Document everything.

That’s how first-time installers become trusted pros.