Turning on your PTAC for the first time feels like a milestone—especially in a start-up space where every system needs to work reliably from day one. But before you press that power button, there’s a short (and very important) phase that often gets rushed: pre-start testing.

These checks don’t require advanced HVAC skills. What they do require is patience and attention to detail. Skipping them can lead to nuisance breaker trips, performance issues, or early service calls—none of which are great when you’re just getting started.

Amana J-Series PTAC Model 17,000 BTU PTAC Unit with 5 kW Electric Heat

In this guide, I’ll walk you through the essential pre-start tests to complete before switching on your Amana PTAC, so your first run is smooth, safe, and stress-free.

🧠 Why Pre-Start Testing Matters (Especially for Start-Ups)

PTACs are designed to be durable and user-friendly—but they’re also powerful electrical appliances. A proper pre-start check helps you:

-

Catch installation issues early

-

Prevent electrical damage

-

Avoid unnecessary warranty claims

-

Ensure efficient heating and cooling from the start

Think of this as your insurance policy before power-up.

🧱 Test 1: Wall Sleeve Fit, Level & Drainage

Before electricity ever enters the picture, confirm the PTAC is physically set up correctly.

🔍 What to Check

-

Unit is fully seated in the wall sleeve

-

Sleeve is level (slight outward tilt is OK for drainage)

-

No gaps between unit and interior wall

-

Outdoor grille is unobstructed

Improper seating can cause vibration, noise, and condensate leaks later on.

🔩 Test 2: Structural Stability & Vibration Check

PTACs move air—and air movement creates vibration if the unit isn’t secured properly.

✔️ Confirm:

-

Mounting screws or brackets are installed

-

Unit does not rock when gently pushed

-

Front panel is secure

A loose PTAC might run fine on day one but develop noise complaints or alignment issues within weeks.

🔌 Test 3: Electrical Supply Verification (Critical Step)

This is the most important pre-start test.

⚡ Verify the Following

-

Correct voltage (commonly 208/230V for Amana PTACs)

-

Dedicated circuit (no shared outlets)

-

Proper breaker size (often 20–30 amps, model-specific)

-

Power cord fully seated, no adapters or extension cords

Do not power on the unit if you’re unsure about electrical compatibility.

👉 Electrical safety guidance:

U.S. Consumer Product Safety Commission – Electrical Safety

🧪 Test 4: Visual Inspection of Internal Components

Before startup, remove the front cover (if manufacturer-approved) and look inside.

👀 Look For:

-

Loose packing material

-

Dislodged filters

-

Visible damage to coils or wiring

-

Anything that “doesn’t look right”

This step alone prevents many first-run failures caused by shipping debris.

👉 General HVAC inspection overview:

Energy.gov – Heat & Cooling Equipment Basics

🌬 Test 5: Airflow Path & Filter Check

Restricted airflow is a silent PTAC killer.

✔️ Confirm:

-

Filter is installed correctly and clean

-

No packaging blocks air intake

-

Front grille opens freely

-

Outdoor airflow path is clear

Never run a PTAC without its filter—it protects both the coil and the compressor.

🎛 Test 6: Control Panel & Thermostat Response

Before full power-up, check that controls respond correctly.

🧠 Test These Settings

-

Power button responsiveness

-

Mode selection (cool / heat / fan)

-

Temperature adjustment

-

Fan speed options

If using an external thermostat, confirm wiring and communication before startup.

👉 How thermostats interact with HVAC systems:

This Old House – Thermostat Basics

🌡 Test 7: Environmental Readiness Check

Your PTAC doesn’t operate in isolation—it reacts to its environment.

🏠 Confirm:

-

Windows and doors near the unit are closed

-

No extreme heat sources nearby

-

Space temperature is within normal range

-

Room isn’t under active construction

This ensures accurate performance readings during the first run.

🧯 Test 8: Safety & Clearance Verification

PTACs generate heat (especially electric heat models), so clearances matter.

✔️ Ensure:

-

No furniture blocks airflow

-

No flammable materials nearby

-

Adequate clearance per manufacturer specs

This protects both the unit and the space it serves.

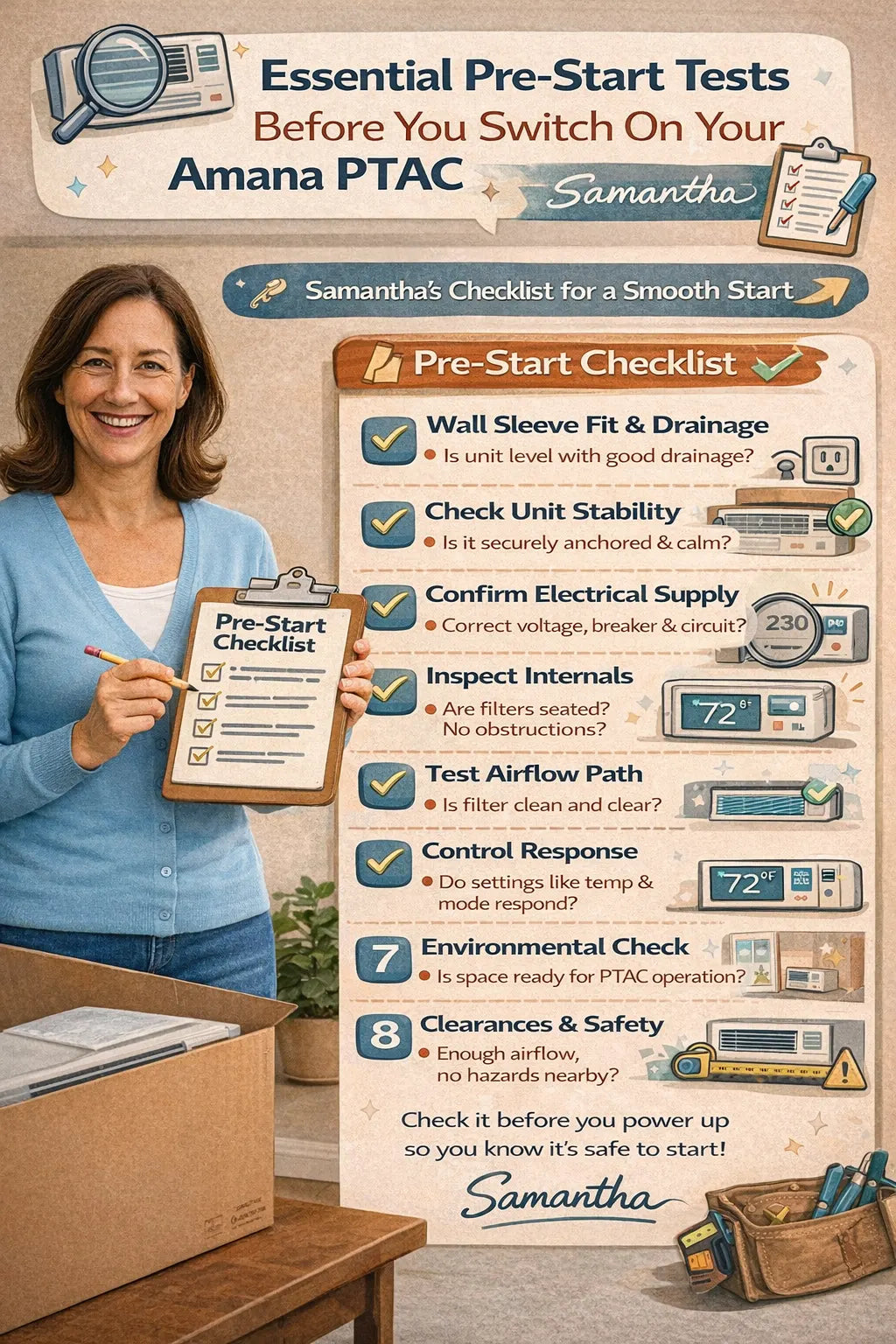

📝 Pre-Start Sign-Off Checklist (Samantha’s Version)

Before switching on your Amana PTAC, you should be able to confidently say:

✔ Unit is level and secure

✔ Electrical supply is correct and dedicated

✔ Airflow is unobstructed

✔ Controls respond properly

✔ No visible damage or loose parts

✔ Space is ready for operation

If all boxes are checked—you’re ready for power-up.

🚀 Why These Tests Save You Time (and Money)

Skipping pre-start tests often leads to:

-

Breaker trips on first run

-

False assumptions about defective units

-

Unnecessary service calls

-

Delayed comfort in your space

Taking 30–45 minutes now can save days of troubleshooting later.

🧠 Final Thoughts from Samantha

Your Amana PTAC is built to perform—but like any system, it performs best when it’s respected from the start.

Pre-start testing isn’t about being overly cautious. It’s about being intentional, especially in a start-up environment where reliability matters more than ever.

Once these checks are complete, you can switch on your PTAC knowing you did it the right way.

And that confidence? It’s worth the extra time.