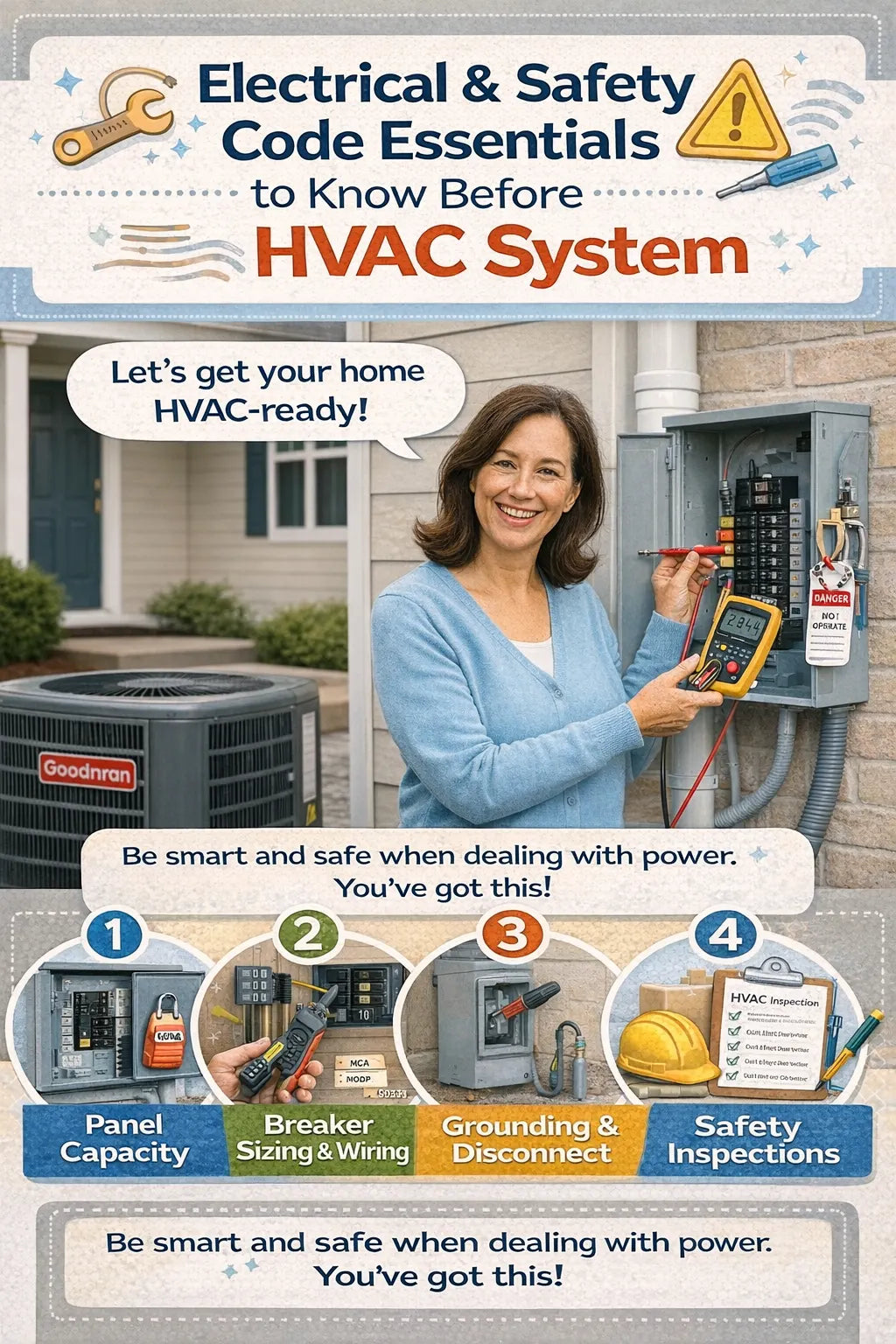

Installing a large HVAC system isn’t just a mechanical project—it’s an electrical and safety project that happens to involve heating and cooling. And while manufacturers design modern systems to be safer than ever, codes exist because mistakes here can cause fires, shock hazards, gas leaks, or long-term system damage.

This guide breaks down the electrical and safety codes that matter most before HVAC installation, explained in plain English so you know what to expect, what to ask for, and when to slow things down.

🧠 Why Electrical & Safety Codes Matter More Than Equipment Specs

I’ll say this plainly:

A perfectly sized, high-efficiency HVAC system can still be unsafe or unreliable if electrical and safety basics are ignored.

Codes exist to:

-

prevent electrical fires

-

reduce shock risk

-

protect equipment from overload

-

ensure safe shutdown during emergencies

-

protect homeowners and technicians

Knowing these essentials helps you spot red flags before installation day—not after something trips, smokes, or fails inspection.

📘 The Big Three Code Frameworks (You’ll Hear These Names)

You don’t need to memorize codes—but you should recognize the sources installers follow.

🔌 National Electrical Code (NEC)

The NEC governs:

-

breaker sizing

-

wire gauge

-

grounding and bonding

-

disconnect requirements

🦺 OSHA Safety Standards

OSHA rules apply primarily to workers, but they shape:

-

lockout/tagout practices

-

ladder safety

-

jobsite electrical handling

🔗 External reference:

https://www.osha.gov/laws-regs/regulations/standardnumber/1910

🏠 Local Building & Mechanical Codes

Your city or county adopts versions of national codes and may add stricter rules. Local code always wins if there’s a conflict.

🔒 Lockout/Tagout: The Most Important Safety Practice You’ll Never See

Before any HVAC work begins, power must be positively disabled and secured.

What proper lockout/tagout (LOTO) means

-

Breakers are shut off

-

A physical lock prevents re-energizing

-

A tag identifies who is working on the system

This prevents someone else (a family member, utility worker, or even another tech) from restoring power mid-job.

🔗 External reference (OSHA LOTO standard):

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.147

If you don’t see some form of lockout during electrical work, that’s a safety concern.

🔋 Electrical Panel Capacity: The Foundation Most Problems Sit On

Large HVAC systems draw significant current, especially at startup.

What should be verified before installation

-

Panel has available breaker space

-

Service amperage can support the new load

-

Panel is in good physical condition

-

No signs of overheating, corrosion, or double-tapped breakers

Common red flags

-

“We’ll just squeeze it in”

-

Using undersized breakers

-

Reusing old wiring not rated for the new load

If a panel upgrade is needed, it should happen before HVAC installation—not as a workaround after tripping issues begin.

🔌 Breaker Sizing & Wire Gauge (Why “Close Enough” Isn’t Enough)

HVAC equipment specifies:

These values are printed on the unit’s data plate and must be followed exactly.

Why this matters

-

Undersized wire → overheating risk

-

Oversized breaker → fire hazard

-

Incorrect pairing → voided warranties

This isn’t preference—it’s code-driven and manufacturer-mandated.

🧯 Grounding & Bonding: Quiet, Critical, Often Overlooked

Grounding and bonding protect people and equipment during faults.

HVAC-specific grounding basics

-

Equipment grounding conductor must be continuous

-

Outdoor condensers must be bonded correctly

-

Metallic gas piping often requires bonding (check local code)

Improper grounding can cause:

-

nuisance tripping

-

electronic board damage

-

shock hazards

Inspectors check this closely—and for good reason.

🔌 Service Disconnects: Your Emergency Stop Button

Every outdoor condenser must have a service disconnect within sight.

What codes generally require

-

Located within visible range of the unit

-

Easily accessible

-

Rated for the circuit amperage

-

Clearly labeled

The disconnect allows:

-

safe servicing

-

emergency shutdown

-

compliance with NEC and mechanical codes

🔗 External reference (NEC disconnect principles):

https://www.nfpa.org/

🌧️ Outdoor Electrical Protection & Weatherproofing

Outdoor HVAC components must survive years of exposure.

Code-driven protections include

-

Weather-rated disconnects

-

Proper conduit and fittings

-

Drip loops to prevent water intrusion

-

Correct sealing at wall penetrations

Improper weatherproofing leads to corrosion, nuisance failures, and electrical shorts—often years later, long after installation.

🔥 Furnace Electrical & Safety Essentials (Gas or Electric Heat)

If your system includes a furnace, additional safety layers apply.

Electrical safety checks

-

Dedicated circuit where required

-

Correct polarity (yes, it matters)

-

Secure low-voltage wiring

-

Proper transformer protection

Safety controls that must never be bypassed

-

limit switches

-

pressure switches

-

rollout sensors

-

flame sensors

Bypassing safeties—even “temporarily”—is a major code and safety violation.

🌬️ Combustion Safety & Electrical Interactions

Modern furnaces rely on electrical controls to manage combustion safely.

Why electrical accuracy matters

-

Pressure switches verify venting

-

Inducer motors must be properly powered

-

Control boards depend on stable voltage

Electrical shortcuts here can create carbon monoxide risks, not just comfort issues.

🔗 External reference (combustion safety fundamentals):

https://www.energy.gov/energysaver/furnaces-and-boilers

💧 Condensate Safety Switches: Not Always Required—Always Smart

While not always mandated by code, condensate overflow switches are increasingly required in:

-

attic installations

-

systems above finished spaces

-

high-efficiency equipment

They prevent:

-

ceiling damage

-

mold growth

-

insurance claims

If your installer recommends one, that’s a good sign—not an upsell.

🧪 Inspections: What They’re Actually Looking For

Electrical and safety inspections typically verify:

-

breaker sizing and labeling

-

conductor sizing and routing

-

grounding and bonding

-

disconnect placement

-

clearances

-

safety control integrity

Passing inspection isn’t a nuisance—it’s proof your system is safe to live with for the next 15–20 years.

🚩 Common Code Red Flags Homeowners Shouldn’t Ignore

If you hear or see these, pause the job:

-

“This passes everywhere”

-

“Inspectors never check that”

-

“We’ll add the disconnect later”

-

“That safety switch causes nuisance shutoffs”

-

exposed wiring

-

missing labels

Good installers respect codes. Great installers explain them.

🧡 Samantha’s Final Advice

Electrical and safety codes aren’t there to complicate your install—they’re there to protect your home, your family, and your investment.

You don’t need to memorize regulations.

You do need to:

-

expect proper shutdown procedures

-

confirm electrical capacity

-

insist on correct breaker and wiring sizes

-

allow inspections to happen

-

never accept bypassed safety controls

Buy this on Amazon at: https://amzn.to/43doyfq

In the next topic we will know more about: Refrigerant Lines and Charging: A Beginner’s Guide Without the Scary Jargon