🔎 Introduction: Mike’s Crossroads

Mike Sanders is no stranger to tools. Over the years, he’s built a deck, swapped a water heater, and even tackled some minor electrical projects. So when his old central AC finally tapped out, he started pricing out a 1.5 ton R‑32 air conditioner.

The sticker shock came fast:

-

Equipment: $4,200

-

Professional Installation: $2,400–$3,000

“I thought, why not just do it myself and save a couple grand?” Mike recalls.

That’s when he faced the big question:

DIY or professional install?

This guide takes you through what Mike learned—the real pros and cons of each approach—so you can make the best call for your home.

🧰 1. Why DIY Sounds So Tempting

💵 The Cost Savings

The average professional installation for a 1.5‑ton system runs $2,000–$3,000 (HomeAdvisor). Skipping labor could cut your project cost nearly in half.

⏱️ Control Over Timing

DIY means no waiting for busy contractors in the middle of summer. Mike figured he could knock out the install in a weekend.

🛠️ Sense of Accomplishment

There’s pride in saying, “I installed my own AC.” Mike admitted the challenge appealed to his DIY side.

📹 Online Tutorials Everywhere

YouTube, blogs, and manufacturer guides make installs look straightforward.

Mike’s mindset at first:

“I’m handy, I’ve got the tools, and I hate writing big checks. How hard can it be?”

⚠️ 2. The Hidden Risks of DIY with R‑32

As Mike dug deeper, reality hit.

📜 EPA Requirements

R‑32 is a mildly flammable refrigerant (classified A2L). The EPA requires certified handling of refrigerants to ensure safe charging and disposal

Most manufacturers, including Goodman and Daikin, require professional installation for the 10‑year parts warranty to remain valid.

🔌 Electrical Hazards

A 1.5‑ton unit requires a dedicated 240V circuit. Mistakes can lead to fire or shock risks.

🔥 Refrigerant Safety

Without a vacuum pump, manifold gauges, and a micron gauge, you can’t properly evacuate or charge the system. And R‑32 leaks, while rare, must be handled carefully (ASHRAE).

🏛️ Code Compliance

Many counties mandate permits and inspections for HVAC work. A DIYer without a licensed installer may not pass inspection.

Mike’s realization:

“I knew how to pour the pad and run thermostat wire. But the refrigerant side? That was a no-go without the license.”

👷 3. What Professionals Bring to the Table

Hiring a pro isn’t just about turning wrenches. It’s about long-term performance.

📐 Correct Sizing with Manual J

-

Contractors use Manual J load calculations to confirm if a 1.5‑ton system is the right size.

-

Oversizing or undersizing leads to poor comfort and higher bills.

💨 Proper Refrigerant Charge

-

Charging too much or too little refrigerant reduces efficiency by 10–20%.

-

Pros use digital gauges and superheat/subcooling methods for precision.

⚡ Safe Electrical Work

-

They ensure breakers, wiring, and disconnects meet NEC code.

-

Install surge protection if recommended.

🛠️ Ductwork Sealing & Balancing

-

Sealed ducts prevent losing 20–30% of cooling into the attic or crawlspace

📊 Post-Install Testing

-

Measure static pressure, airflow, and efficiency.

-

Verify SEER2 performance matches specs.

📊 4. Mike’s Real Experience

🏗️ Mike’s Plan

He researched:

-

Buying a vacuum pump, recovery tank, gauges, and a refrigerant scale (≈$600–$1,000).

-

Pulling a permit in his county ($350).

-

Watching 20+ hours of tutorials.

💡 The Deal Breakers

-

Permit Office: Told Mike a licensed contractor was required for the refrigerant hookup.

-

Warranty Terms: Manufacturer warranty void without pro install.

-

Safety Risks: A friend (an HVAC tech) warned him about fire risk from improper line set brazing with R‑32.

✅ Final Decision

Mike hired a pro for the hookup and testing but did prep work himself.

-

Professional Labor: $2,400

-

Mike’s DIY Prep Savings: $500+

-

Peace of Mind: Priceless

🏠 5. The Hybrid Approach: Best of Both Worlds

Mike discovered he could still flex his DIY muscles:

🔨 Tasks Mike Did Himself

-

Pad Prep: Poured and leveled a 3’x3’ concrete pad.

-

Thermostat Wiring: Ran low-voltage wire through the walls.

-

Smart Thermostat Install: Set up a Nest thermostat.

-

Ductwork Touch-Ups: Sealed minor leaks with mastic.

💵 Savings Earned

-

Pad prep: Saved $200

-

Thermostat wiring: Saved $150

-

Smart thermostat: Installed himself, saved $150

-

Duct sealing: Saved $100+

Total savings: ~$600

💡 6. Long-Term Value of Professional Installation

⚡ Lower Utility Bills

-

Correct refrigerant charge = maximum efficiency.

-

Mike’s first July bill dropped $35 compared to his old system.

🔧 Fewer Breakdowns

-

Avoided compressor strain from incorrect charge.

-

System warranty protects against costly failures.

🏡 Higher Resale Value

-

Buyers and inspectors love documented professional installation.

🛡️ Warranty Protection

-

Goodman’s 10-year parts warranty only valid with pro install.

Mike’s verdict:

“The upfront cost hurt. But knowing the system is safe, efficient, and covered? Worth every penny.”

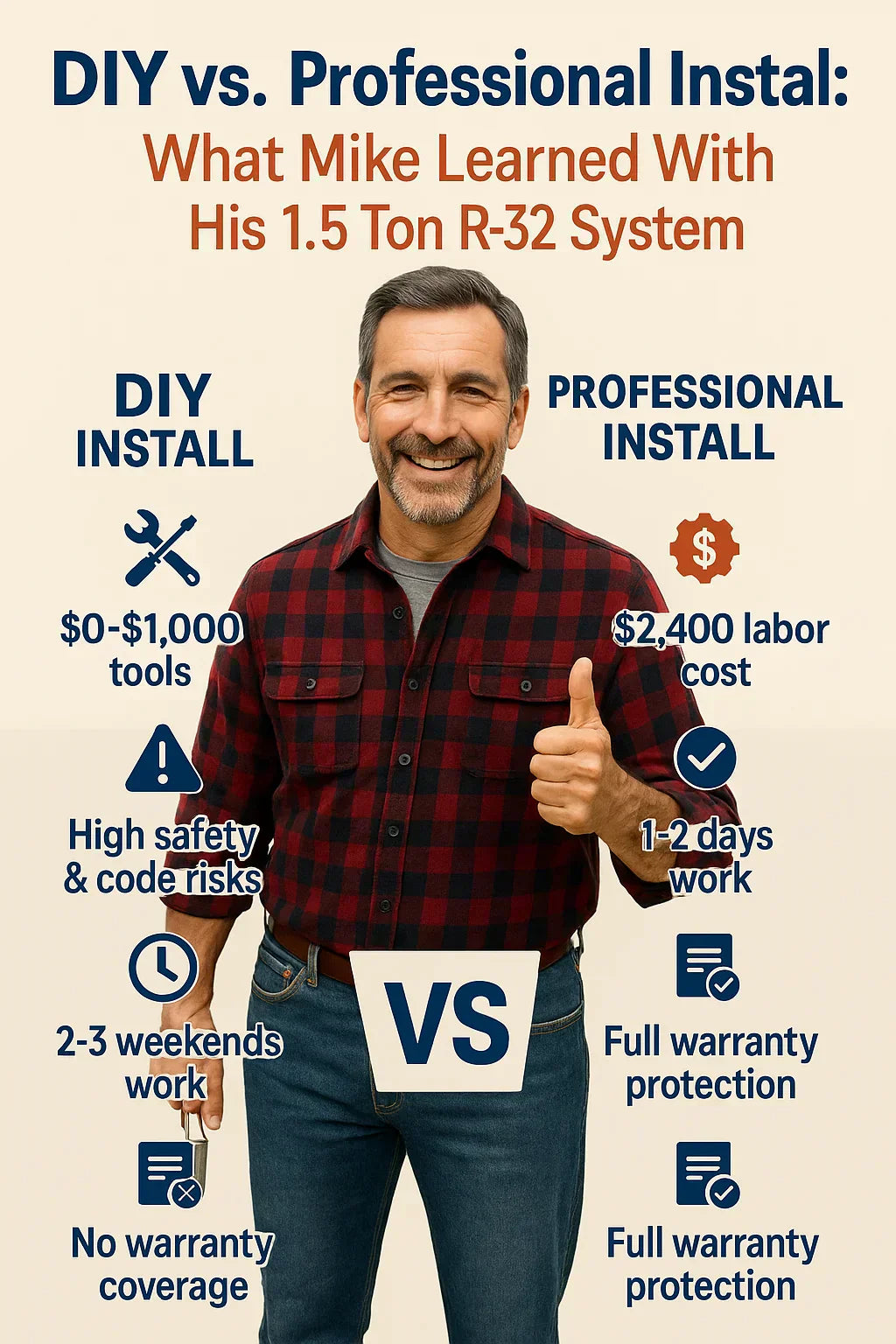

📊 7. DIY vs. Pro: Side-by-Side Comparison

| Factor | DIY Install | Professional Install |

|---|---|---|

| Upfront Cost | $0–$1,000 tools + $4,200 unit | $2,400–$3,000 labor + $4,200 unit |

| Warranty | Voided in most cases | Full 10‑year coverage |

| Safety | High risk: electrical & refrigerant | Low risk: certified work |

| Code Compliance | Often fails inspection | Guaranteed pass |

| Time Commitment | 2–3 weekends + stress | 1–2 days |

| Long-Term Bills | Higher from inefficiency | Lower from precision setup |

🛠️ 8. Tools You’d Need for DIY (and Why Mike Passed)

-

Vacuum Pump: $150–$300

-

Refrigerant Gauges & Micron Gauge: $200+

-

Brazing Torch + Nitrogen Kit: $250–$400

-

Recovery Tank: $150

-

Electrical Tools & Disconnect Kit: $100–$200

Total DIY tool investment: $800–$1,200

Still without a warranty or code compliance.

✅ Conclusion: Mike’s Final Word

Mike’s journey showed him that while DIY looked appealing, the risks outweighed the savings. By doing the prep work himself and letting pros handle the refrigerant and electrical, he:

-

Saved $600

-

Kept his 10‑year warranty

-

Lowered his bills with a properly charged, efficient system

-

Slept better knowing the job was safe and code‑compliant

“If you’re like me, do what you can—prep, wiring, even the thermostat. But when it comes to R‑32, let the pros handle the critical steps.”

In the next topic we will know more about: Maintenance Checklist: Keeping Your 1.5 Ton R-32 AC Running Like New