Furnaces don’t have emotions.

But control boards absolutely have memory.

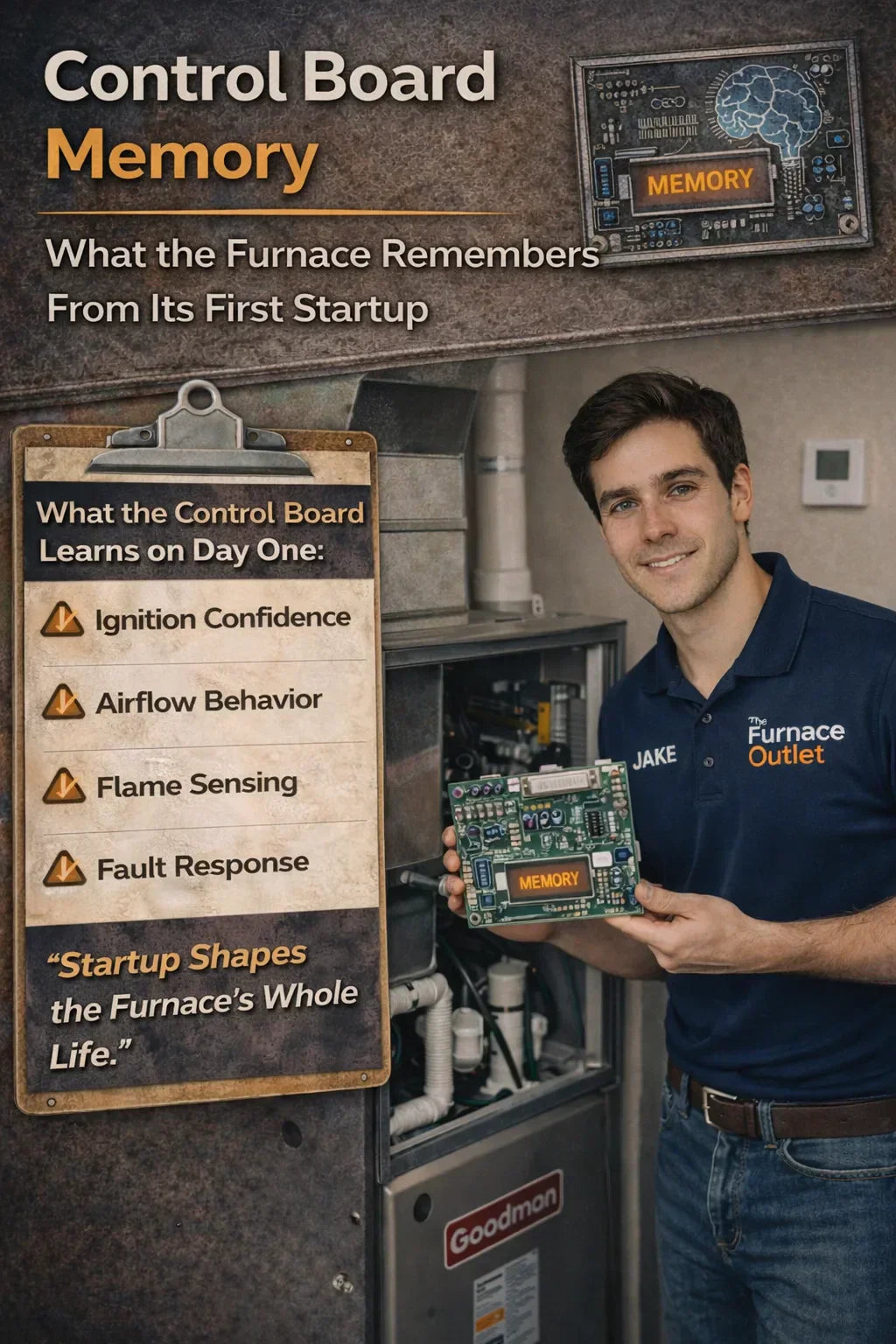

And the way a furnace behaves for the rest of its life is heavily influenced by what it experiences during its very first startup.

I’ve seen furnaces that ran clean for 15 years.

I’ve seen identical models become chronic problem children.

Same brand.

Same house size.

Same installer.

The difference wasn’t the equipment.

It was what the control board learned on day one.

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

🔌 The Myth: “Once It’s Running, It’s Fine”

Most people think startup ends when the furnace lights and stays lit.

That’s not startup. That’s ignition.

Startup is when the control board:

-

Establishes baseline behavior

-

Logs early fault conditions

-

Learns timing relationships

-

Responds to stress for the first time

And control boards don’t forget early lessons.

They adapt.

🧠 What “Memory” Really Means in a Furnace

Modern furnace control boards:

-

Track fault histories

-

Adjust retry behavior

-

Modify timing based on conditions

-

React differently after repeated events

Even if a board doesn’t store permanent fault codes, it still responds based on what it’s seen before.

A furnace that struggled on its first day will behave more cautiously — and sometimes more aggressively — for the rest of its service life.

🔄 Early Lockouts Change Future Behavior

One of the worst things you can do during startup is cause unnecessary lockouts.

Why?

Because early lockouts teach the board:

-

“Conditions here are unstable”

-

“I may need to retry more often”

-

“I may need to shut down sooner”

I’ve seen systems where:

-

First-day lockouts led to nuisance shutdowns later

-

Boards became hypersensitive to minor fluctuations

-

Homeowners complained about “random” faults

Nothing was random.

The furnace remembered.

🔥 Flame Sense Lessons Are Learned Immediately

The first few ignition cycles teach the board:

-

How strong flame rectification should look

-

How fast flame should be proven

-

What “normal” flame signal strength feels like

If flame signal is marginal during startup:

-

Due to grounding

-

Due to gas pressure behavior

-

Due to airflow interference

The board adapts around weakness instead of learning strength.

Honeywell’s combustion control documentation explains how flame sensing behavior influences control logic decisions over time

🌬️ Airflow Struggles Get Written Into the Script

If airflow is restricted during startup:

-

Blower ramps aggressively

-

Limits may flirt with trip points

-

Cabinet pressure fluctuates

The control board responds by:

-

Adjusting blower behavior

-

Shortening or extending cycles

-

Reacting defensively to temperature rise

Later, when airflow improves slightly, the board doesn’t instantly forget what it learned.

It still behaves cautiously.

That’s why airflow mistakes on day one haunt systems for years.

⚠️ Pressure Switch Behavior Leaves a Mark

Pressure switches don’t just open or close.

They:

-

Open late

-

Close slow

-

Flutter under marginal conditions

If the control board sees:

-

Delayed pressure closure

-

Inconsistent inducer response

-

Borderline venting behavior

It adapts by:

-

Extending pre-purge

-

Increasing retries

-

Becoming more sensitive to small changes

ASHRAE notes that repeated marginal pressure events can condition control responses, even if faults are not permanently logged:

https://www.ashrae.org/technical-resources

🔁 Why “It Was Fine at First” Is a Red Flag

When a homeowner says:

“It worked fine at first… then started acting up,”

That tells me:

-

Startup conditions were marginal

-

The control board compensated

-

Environmental changes exposed the weakness

The board didn’t suddenly fail.

It reached the limit of what it learned to tolerate.

🧪 Controlled Startup Builds Confident Memory

This is why I:

-

Avoid rushed startups

-

Avoid unnecessary failures

-

Verify clean recovery when testing safeties

-

Confirm stable operation over multiple cycles

I want the control board to learn:

-

Clean ignition

-

Stable airflow

-

Confident flame signal

-

Predictable timing

A calm startup creates a calm furnace.

🧯 Why Early Faults Matter More Than Later Ones

A fault on day one says:

“This is normal here.”

A fault after five years says:

“Something changed.”

Control boards treat those two situations very differently.

That’s why I’m more careful during startup than during service calls.

Startup is when the board sets expectations.

🧾 What I Document to Protect the Board’s “Memory”

My startup notes don’t just protect me.

They protect the system.

I record:

-

Number of clean ignition cycles

-

No early lockouts

-

Stable flame signal

-

No pressure switch hesitation

-

Consistent blower behavior

Because when something happens years later, I know:

-

Whether the system changed

-

Or whether it was always borderline

🛠️ Tools Help — Consistency Teaches

Yes, I use tools.

But tools don’t teach the control board.

Consistency does.

A furnace learns from repetition, not perfection.

🏠 Why Homeowners Never See This Coming

Homeowners don’t know:

-

What a control board saw on day one

-

How early behavior shaped later reactions

-

Why “random” faults aren’t random

They just know:

“It’s always been a little weird.”

And that’s usually true — from the very first startup.

🧠 Jake’s Rule on Control Board Memory

If the furnace struggles on day one,

it will remember how to struggle.

If the furnace runs clean on day one,

it learns confidence.

Startup isn’t just about making heat.

It’s about teaching the control board how to behave for the rest of its life.

🔚 Final Thought: You Only Get One First Impression

Control boards don’t get do-overs.

They don’t forget bad introductions.

And they don’t magically unlearn poor startup conditions.

If you want a furnace that:

-

Starts clean

-

Runs quietly

-

Recovers gracefully

-

Rarely calls you back

Then give the control board a good first memory.

Because it will carry that lesson longer than you think.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: Single-Stage Doesn’t Mean Simple: Jake’s Timing Map for the GR9S960803BN