Jake’s Startup Trap That Saves Secondary Heat Exchangers

High-efficiency furnaces don’t usually die dramatically.

They rot.

Slowly. Quietly. Invisibly.

And most of the time, the damage starts on day one — during startup — when condensate isn’t handled the way the furnace expects.

I’ve seen secondary heat exchangers fail that were barely out of warranty.

I’ve seen pressure switch problems that made no sense on paper.

I’ve seen furnaces that “just never ran right” from the first winter.

And almost every time, the root cause was the same:

The condensate system wasn’t treated as part of startup.

80,000 BTU 96% AFUE Upflow/Horizontal Single Stage Goodman Gas Furnace - GR9S960803BN

🧠 Why Condensate Is a Startup Issue (Not a Maintenance One)

Most installers think condensate is something you deal with later:

-

If it leaks

-

If it freezes

-

If it backs up

That’s already too late.

On a 90%+ furnace, condensate management is combustion management.

From the first ignition:

-

Acidic moisture is forming

-

Pressure relationships depend on water seals

-

Draft is influenced by liquid, not just air

If the condensate system isn’t correct at startup, the furnace never truly stabilizes.

🔥 What Condensate Is Really Doing Inside the Furnace

Condensate isn’t just water.

It’s:

-

Acidic (carbonic acid from combustion)

-

Warm

-

Reactive with metals

-

Part of the pressure system

Inside a high-efficiency furnace, condensate:

-

Forms in the secondary heat exchanger

-

Drips into the collector box

-

Passes through a trap

-

Maintains a pressure seal for proper draft

That trap isn’t optional. It’s functional.

The Gas Technology Institute explains how condensate and pressure balance are integral to condensing furnace operation, not a byproduct:

https://www.gti.energy

🚫 The #1 Startup Mistake: Dry Trap Ignition

Here’s the fastest way to shorten a furnace’s life:

Start it with a dry trap.

A dry trap causes:

-

Pressure switch instability

-

Delayed ignition

-

Inducer surging

-

Combustion byproducts backing up where they shouldn’t

And worst of all:

-

Acidic condensate splashing internally instead of draining cleanly

Once the secondary heat exchanger starts seeing improper drainage, corrosion accelerates.

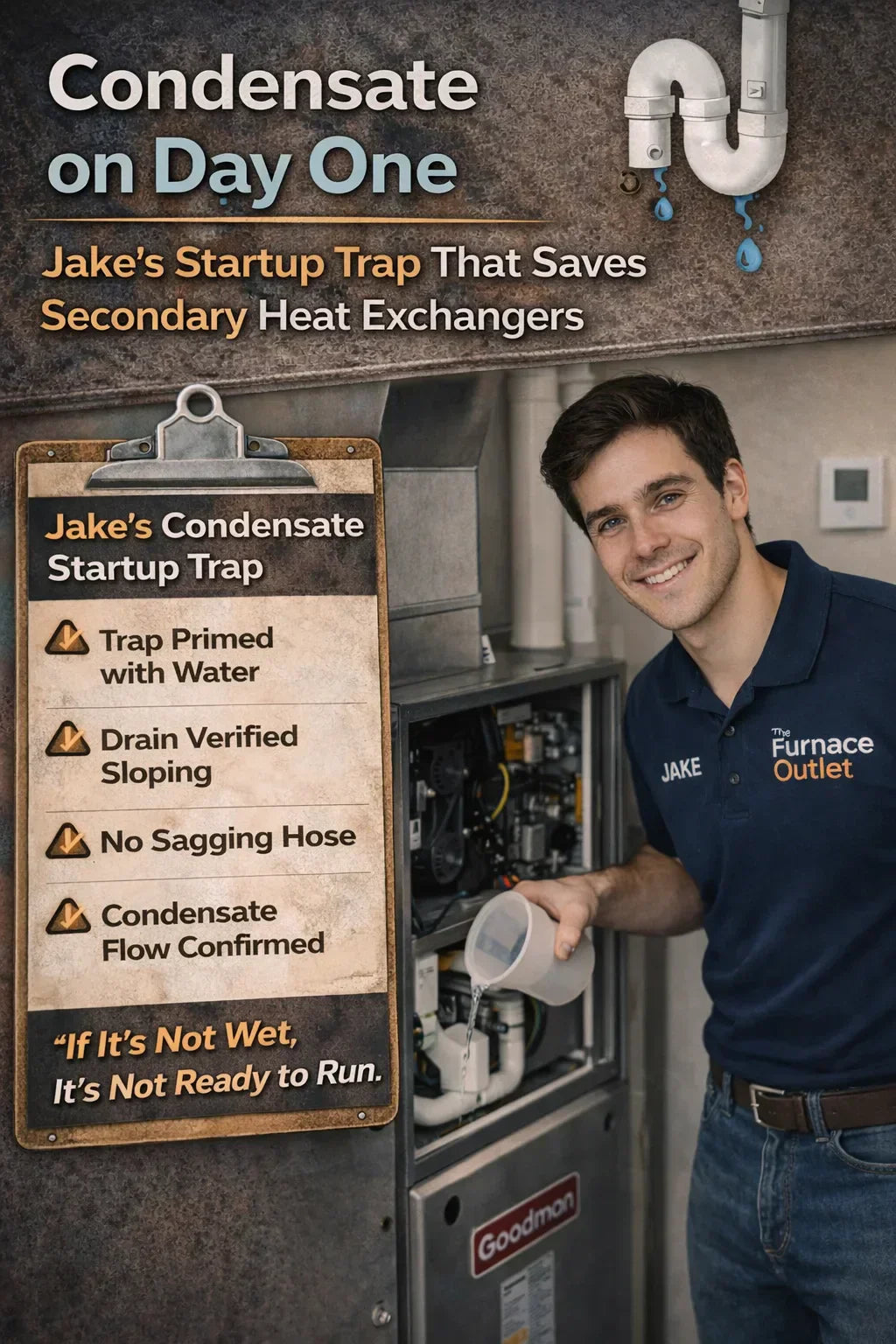

💦 Jake’s Rule: If It’s Not Wet, It’s Not Ready

Before I ever power a high-efficiency furnace, I confirm:

-

Trap installed

-

Trap primed

-

Drain line pitched

-

No air gaps

-

No sagging hose runs

I physically pour water into the trap.

Every time.

Because a furnace that starts dry is already stressed.

📐 Drain Pitch: Gravity Doesn’t Negotiate

Condensate doesn’t forgive poor pitch.

During startup, I trace the entire drain path:

-

From collector box

-

Through the trap

-

To the termination

I’m looking for:

-

Continuous downward slope

-

No dips that hold water

-

No uphill sections “that usually work”

-

No soft vinyl lines sagging after install

Standing water creates:

-

Algae growth

-

Freeze points

-

Pressure irregularities

-

Acid concentration

ASHRAE’s condensate disposal guidance stresses proper slope and drainage to prevent operational and corrosion issues:

https://www.ashrae.org/technical-resources

🌬️ Pressure Switch Problems That Aren’t Pressure Switch Problems

When someone says:

“This furnace has a bad pressure switch,”

I immediately check condensate.

A partially blocked or improperly trapped drain:

-

Changes internal pressure

-

Delays switch closure

-

Causes intermittent faults

-

Mimics venting problems

Replacing the switch doesn’t fix the cause.

Startup condensate setup does.

🧪 Why Day-One Condensate Is the Most Dangerous

Here’s what most people don’t realize:

The first few hours of operation produce the most aggressive condensate.

Why?

-

Fresh metal surfaces

-

Cold heat exchangers

-

Maximum condensation rates

-

High acid concentration

If that condensate isn’t drained and sealed correctly on day one, it attacks the secondary exchanger immediately.

You don’t see the damage for years — but it starts instantly.

The U.S. Department of Energy notes that improper condensate handling contributes to premature failure in condensing furnaces

🧯 Freeze Protection Starts at Startup

If the furnace is installed in:

-

A garage

-

An attic

-

A crawlspace

-

An exterior wall closet

I plan freeze protection before startup, not after the first winter.

That means:

-

Insulating drain lines

-

Avoiding exterior terminations when possible

-

Preventing traps from sitting in cold air paths

Frozen condensate lines don’t just stop drainage — they force acidic water back into the furnace.

🔄 Trap Design: Factory Isn’t Always Final

Some factory traps:

-

Are undersized

-

Sit too low

-

Require repositioning

-

Need support to prevent sagging

I don’t assume the factory configuration is ideal for every install.

Startup is when I confirm:

-

Trap orientation

-

Accessibility

-

Long-term serviceability

If I wouldn’t want to clean it later, I don’t leave it that way now.

🛠️ Tools Help — Water Tells the Truth

You don’t need fancy tools to test condensate.

I use:

-

Water

-

Gravity

-

My eyes

But no tool replaces watching water move where it’s supposed to go.

🧾 What I Document About Condensate

My startup notes include:

-

“Trap primed”

-

“Drain pitched and flowing”

-

“No standing water”

-

“Condensate observed during run”

Because when someone says:

“It smells weird when it runs,”

I know whether condensate was handled correctly from day one.

🏠 Why Homeowners Never Suspect Condensate

Homeowners notice:

-

Noise

-

Heat

-

Smells

-

Error codes

They don’t notice water slowly attacking metal.

So when secondary heat exchangers fail, it feels sudden.

It’s not.

It’s cumulative — and it starts at startup.

🧠 Jake’s Rule on Condensate

If the furnace can’t drain correctly, it can’t breathe correctly.

If it can’t breathe correctly, everything else becomes a guess.

Condensate isn’t a side system. It’s part of combustion.

And day one is when you either protect the furnace — or quietly shorten its life.

🔚 Final Thought: Water Is Patient

Condensate doesn’t rush.

It just keeps doing what it does:

-

Dripping

-

Collecting

-

Reacting

If you respect it during startup, it behaves for decades.

If you ignore it, it waits.

And then one day, the furnace fails — and everyone wonders why.

Buy this on Amazon at: https://amzn.to/48HGh2g

In the next topic we will know more about: Control Board Memory: What the Furnace Remembers From Its First Startup