When I replaced my old heating system, everyone kept asking me the same thing: “Why not get one of those new high-efficiency condensing boilers?” On paper, they look amazing: 95%+ AFUE, compact, modern controls, and rebates. But when I dug deeper — and talked to a few seasoned HVAC pros — I realized something:

👉 If you want a system that will still be running 20–30 years from now, you stick with cast iron.

That’s why I chose the Weil-McLain CGI-4 Series 4, 90,000 BTU cast iron natural gas boiler. And here’s why I still trust cast iron boilers, especially Weil-McLain, to keep my home warm for the long haul.

🧱 Cast Iron = Built for Decades

The single biggest reason cast iron boilers last so long? The material itself.

-

Cast iron heat exchangers are thick, heavy, and resistant to corrosion.

-

They handle scale and mineral deposits better than aluminum or steel.

-

Less sensitive to water chemistry than condensing boilers.

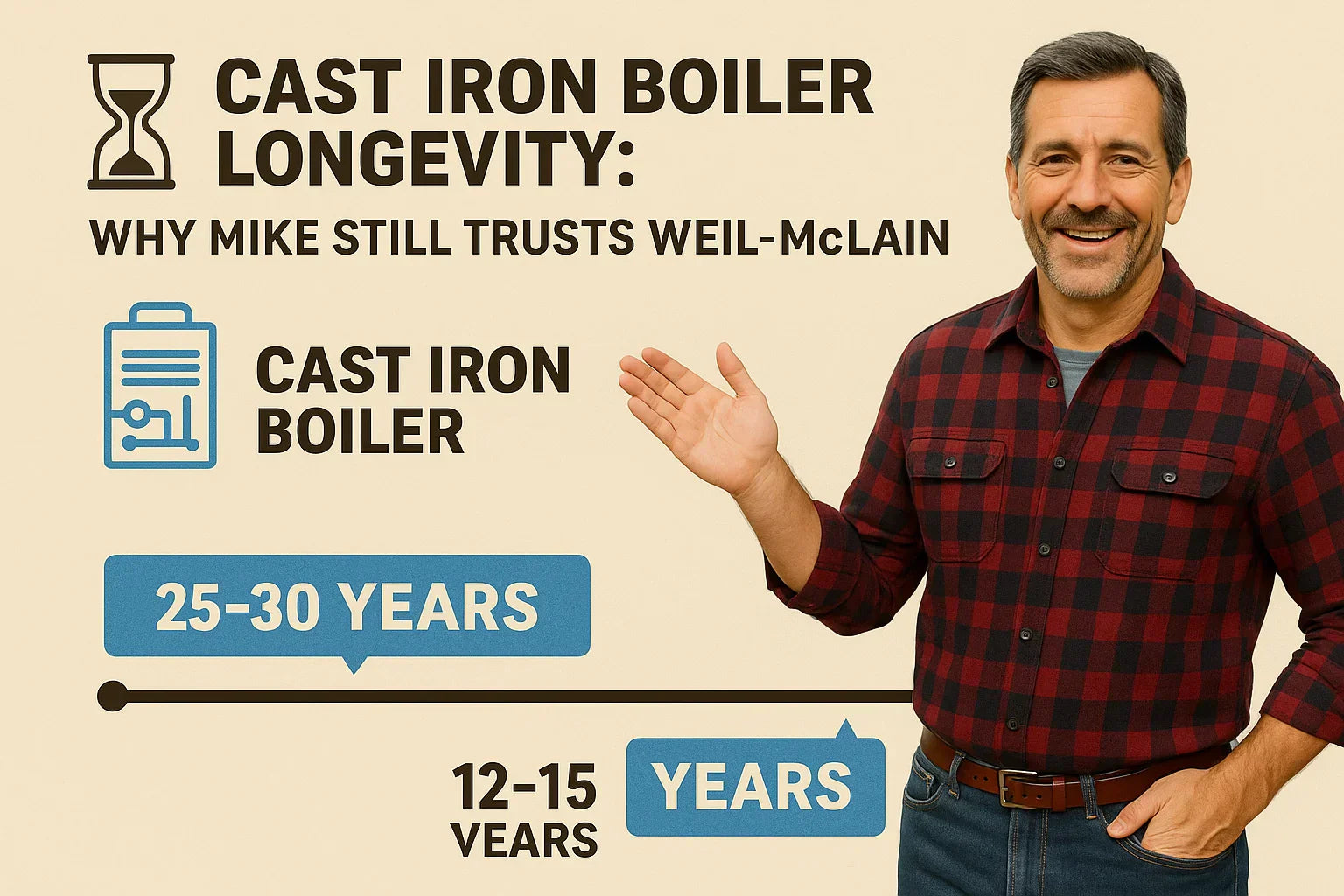

Real-world lifespan

-

Cast iron boilers: 20–30 years (sometimes even 40 with good care).

-

Condensing boilers: 12–15 years on average, due to delicate parts and corrosion risks.

💡 Mike’s Note: My old Weil-McLain boiler lasted 26 years before I replaced it. It wasn’t dead — I just wanted an upgrade before winter.

🔧 Simplicity = Reliability

Another reason I stick with cast iron: fewer moving parts.

Cast Iron Boiler Design

-

No condensate drain lines to clog or freeze.

-

No exhaust fans or plastic vent pipes that can crack.

-

Minimal electronics — most parts are mechanical and easy to replace.

Condensing Boiler Design

-

Relies on sensors, fans, and condensate drains.

-

More efficient, but more delicate.

-

Repairs often require specialized parts.

🔗 This Old House – Boiler Basics

💡 Mike’s Note: With my CGI-4, the most “high-tech” component is the aquastat. If it ever fails, a replacement is $200 — not $2,000.

⚡ Efficiency vs. Longevity

Here’s the tradeoff every homeowner faces:

-

Condensing boilers hit 95%+ AFUE. They save gas in mild weather, especially when return water temps are low. But they require perfect conditions and regular maintenance to stay efficient.

-

Cast iron boilers run at 82–84% AFUE. Less efficient on paper, but their long service life often makes them more economical in the long run.

Example Cost Comparison (20 Years)

-

Condensing boiler: $6,500 install + $1,200/year gas (saves 15%) + $4,000 repairs/replacement after 15 years = ~$33,500 total.

-

Cast iron boiler: $7,500 install + $1,400/year gas + $2,000 repairs = ~$37,500 total.

Not a huge difference — and for me, reliability and fewer headaches won the day.

🔗 Energy.gov – Boiler Efficiency

💡 Mike’s Note: I value not worrying about my heat in a blizzard more than squeezing out a few percent of efficiency.

🏆 Why Weil-McLain in Particular?

There are other cast iron boiler brands, but I trust Weil-McLain for three big reasons:

1. Proven Track Record

-

Over 130 years in the boiler business.

-

Manufactured in the U.S.

-

Reputation for reliability among contractors.

2. Parts & Service Availability

-

Almost every supply house carries Weil-McLain parts.

-

Large nationwide service network.

3. Contractor Preference

-

Many HVAC pros cut their teeth on Weil-McLain installs.

-

Simple design = easy to service, fewer callbacks.

💡 Mike’s Note: When I asked three contractors what brand they’d install in their own homes, all three said Weil-McLain.

⏳ Longevity Factors Homeowners Control

Of course, no boiler lasts 30 years without some help. Here’s what you can do:

-

Annual Tune-Up

-

Cleaning burners, checking safeties, testing efficiency.

-

$150–$300 per year.

-

-

System Flushing

-

Removes sediment that can reduce heat transfer.

-

Every 3–5 years recommended.

-

-

Monitor Pressure & Expansion Tank

-

Keep pressure around 12–15 psi.

-

Replace or recharge expansion tank as needed.

-

-

Keep a Logbook

-

Record maintenance dates and pressure readings.

-

Helps catch problems early.

-

🔗 HVAC.com – Boiler Maintenance Checklist

💡 Mike’s Note: My old logbook helped me catch a failing expansion tank before it damaged the relief valve.

📋 Real-World Examples

My Neighbor’s Burnham vs. My Weil-McLain

-

Neighbor’s Burnham (cast iron) lasted 22 years before a major heat exchanger crack.

-

My Weil-McLain went 26 years with only minor repairs.

Contractor’s Story

-

Local HVAC pro told me he sees condensing boilers failing after 10–12 years, especially in hard water areas.

-

Meanwhile, cast iron units from the ’80s are still running strong.

🛑 When Cast Iron Might Not Be the Best Fit

I’ll be honest: cast iron isn’t for everyone.

-

If you live in a mild climate with low heating demand, a condensing boiler may save more on fuel.

-

If you’re chasing rebates and federal tax credits, most require 95% AFUE+, which excludes standard cast iron models.

-

If space is tight, condensing boilers are more compact and wall-mounted.

👉 But for cold-climate, long-term homeowners like me? Cast iron still wins.

🔗 Energy Star – Federal Tax Credit Info

📝 Mike’s Final Word

The reason I still trust Weil-McLain cast iron boilers comes down to three words: longevity, reliability, and trust.

-

Longevity: 20–30 years is realistic, not a sales pitch.

-

Reliability: Simple design means fewer things break.

-

Trust: Weil-McLain’s history and service network back it up.

For me, that’s worth more than chasing the latest efficiency trends. If you want a boiler that will outlast your car, your appliances, and maybe even your roof, cast iron is still king. And in the cast iron world, Weil-McLain still leads the pack.

In the next topic we will know more about: Sizing Guide: Is 90,000 BTUs Enough for Your Home?