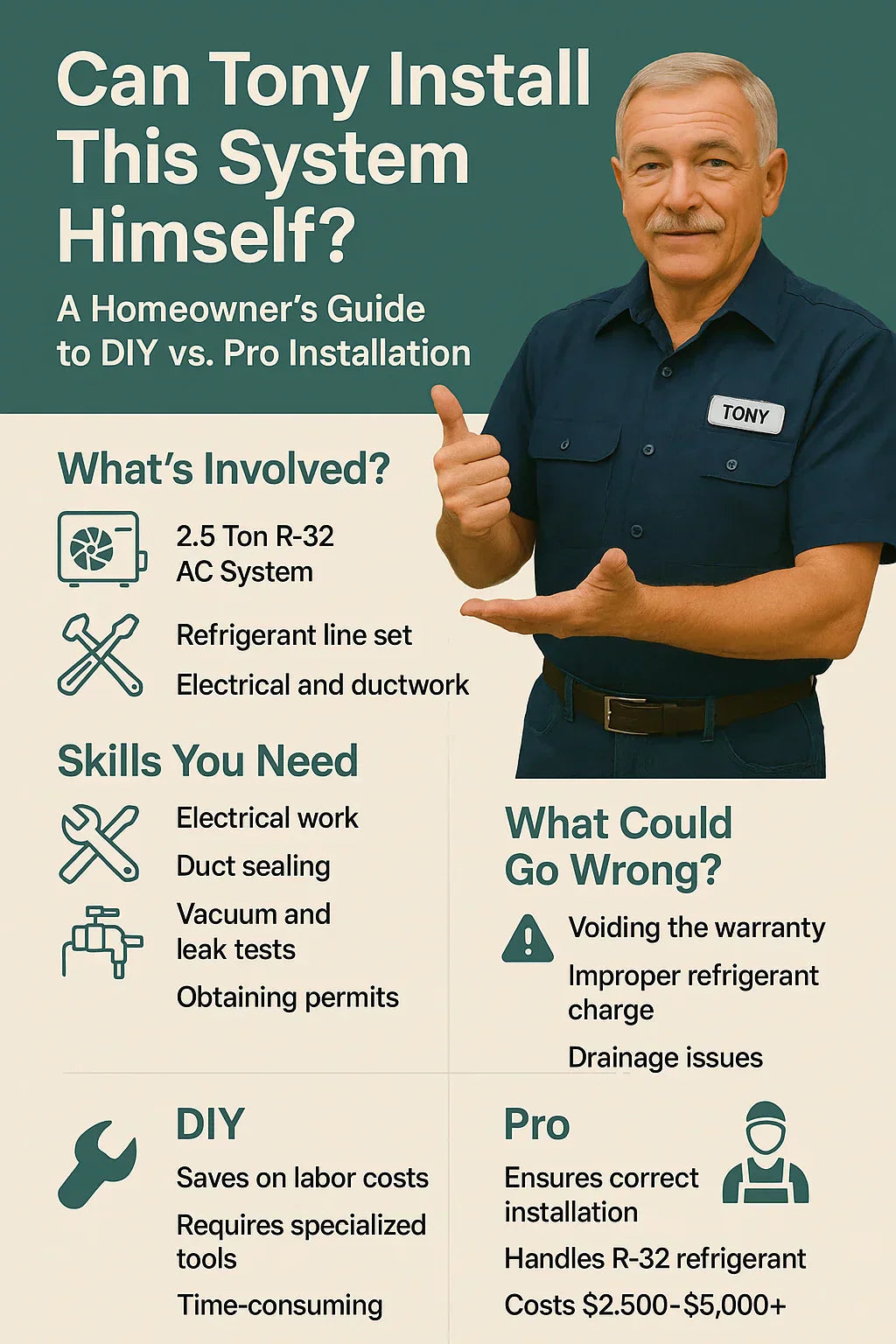

Tony’s the kind of guy who owns a socket wrench set, watches YouTube tutorials before breakfast, and doesn’t mind getting his hands dirty. So when it comes time to install a new 2.5 Ton R-32 air conditioning system in his home, his first question isn’t which contractor to call — it’s can I do this myself?

With rising installation costs, an increasing number of homeowners like Tony are exploring the DIY route for HVAC upgrades. But with new refrigerants like R-32 and tighter efficiency standards in play, is installing your own system still a good idea?

This guide breaks down the reality of DIY vs. professional installation, so Tony (and you) can make the smartest decision for your home, wallet, and long-term comfort.

What’s Involved in Installing a 2.5 Ton R-32 AC System?

At first glance, it might seem simple: hook up the outdoor unit, connect the indoor air handler, wire a thermostat, and enjoy cool air. But let’s unpack what the install really requires:

-

Indoor Air Handler Installation: Mounting, duct connections, condensate drainage, electrical tie-ins.

-

Outdoor Condenser Placement: Pad leveling, proper airflow clearance, vibration reduction.

-

Refrigerant Line Set: Sizing, insulation, leak-free connection, evacuation, and R-32 refrigerant charge.

-

Electrical Work: Disconnect box, circuit breaker, whip, and system wiring.

-

Control Systems: Thermostat compatibility and low-voltage wiring.

Add to that safety, code compliance, and manufacturer-specific steps, and you’ve got a complex multi-day project.

Skills You Need for a Safe and Successful DIY Install

Tony might be skilled, but HVAC installation isn’t casual home improvement. You’ll need:

-

Electrical Knowledge: Know how to safely work with 240V circuits and wiring codes.

-

HVAC Tools Proficiency: Use of a manifold gauge set, vacuum pump, torque wrench, and leak detectors.

-

Ductwork Skills: Understanding airflow, static pressure, and duct sealing best practices.

-

Refrigerant Handling: R-32 is mildly flammable (A2L classification) and under high pressure.

-

Permitting Savvy: Most jurisdictions require HVAC permits and inspections, even for DIYers.

Tools, Permits & Materials Checklist

Here’s what Tony would need to gather before starting:

Essential Tools:

-

Vacuum pump

-

Manifold gauge set (R-32 compatible)

-

Flaring tool

-

Torque wrench

-

Multimeter

-

Leak detector

Installation Materials:

-

Line set (length matched to your install)

-

Wall sleeve and grommets

-

Condensate drain line

-

Electrical whip and disconnect box

-

AC pad (concrete or composite)

-

Sealant, zip ties, wire nuts, duct tape

Permits & Paperwork:

-

Mechanical permit from city/county

-

Inspection scheduling

-

Potential proof of EPA Section 608 certification for refrigerant work

What Could Go Wrong with a DIY Install?

DIY has potential, but it also comes with risk:

-

Warranty Voiding: Most R-32 systems require certified installation for the warranty to remain valid.

-

Improper Refrigerant Charge: Over- or undercharging can reduce efficiency and damage components.

-

Electrical Hazards: One small wiring mistake could trip breakers or start a fire.

-

Drainage Errors: Poor drainage setup can cause water leaks and mold issues.

-

System Sizing Mistakes: Even if the unit is right, ductwork or airflow issues can cause poor performance.

When a Pro Makes Sense

There are strong arguments for hiring an HVAC professional:

-

R-32 Expertise: Proper handling and charging of mildly flammable refrigerant.

-

Faster Installation: Pros can complete what might take Tony a week in just one day.

-

Permitting & Inspection: Contractors know the local code inside and out.

-

Peace of Mind: Knowing it was done right, and that service is just a phone call away.

Cost Range: $2,500 to $5,000+ for full install, depending on region and install complexity.

Blended Option: DIY Prep, Pro Finish

Many savvy homeowners choose a hybrid approach:

-

What You Can Do:

-

Prepare the pad and site

-

Install wall sleeve and line set path

-

Run low-voltage thermostat wires

-

-

What the Pro Does:

-

Connect refrigerant lines and vacuum the system

-

Wire high-voltage safely

-

Verify charge and test pressures

-

This option can cut $500–$1,000 off install costs while ensuring R-32 handling and code compliance are handled professionally.

Tony’s Decision: Go DIY, Pro, or Hybrid?

Tony is handy, but not an HVAC tech. After reviewing tool costs, safety requirements, and the warranty fine print, he decides to do the prep work himself:

-

Clear the install space

-

Lay the pad

-

Install the wall sleeve

-

Run the thermostat wire

Then, he calls a licensed pro to handle the refrigerant line, system vacuum, charge, and final inspection.

Final Take: Should You DIY Your 2.5 Ton R-32 AC System?

Ask yourself:

-

Are you confident working with electrical and refrigerant systems?

-

Can you obtain the right permits and follow code?

-

Do you want to keep your warranty valid?

-

Is it worth saving a few thousand dollars if you risk costly mistakes?

DIY isn’t impossible, but it isn’t for everyone.

Tony made the smart call by splitting the job and leaning on a pro for the high-stakes parts. That way, he saved money, kept his warranty, and gained peace of mind.

Further Resources

Want to install your own 2.5 Ton R-32 system like Tony? Start with prep, know your limits, and don’t be afraid to call in help when it counts.

In the next topic we will know more about: Do 2.5 Ton R-32 ACs Qualify for Energy Rebates or Federal Tax Credits?