By Mark – homeowner, landlord, and guy who learned the hard way that where you put your detector matters just as much as which detector you buy.

🏠 Introduction: Why Placement Matters

When I first bought my Daikin D4120 duct smoke detector, I thought the hard part was over. I had the unit, I had the sampling tubes, and I had my drill ready. My plan was to mount it right near the filter because, hey, that seemed convenient.

Big mistake.

The inspector flagged it immediately. “Too much turbulence here,” he said. “Move it upstream.”

That experience taught me that placement is not optional. If you don’t install a duct smoke detector with the right clearance and airflow, you’re going to:

-

Fail inspection.

-

Get nuisance alarms.

-

Or worse—have a detector that doesn’t actually catch smoke.

This guide is everything I wish I had known before I cut into my duct the first time.

📐 Size & Clearance Requirements

Before you worry about airflow, you need to know if the detector will physically fit in your system.

🔹 Housing Dimensions

The Daikin D4120 (System Sensor D4120) is about:

-

14” long x 5” wide x 6” deep.

-

Requires space on the duct wall plus clearance for tubes.

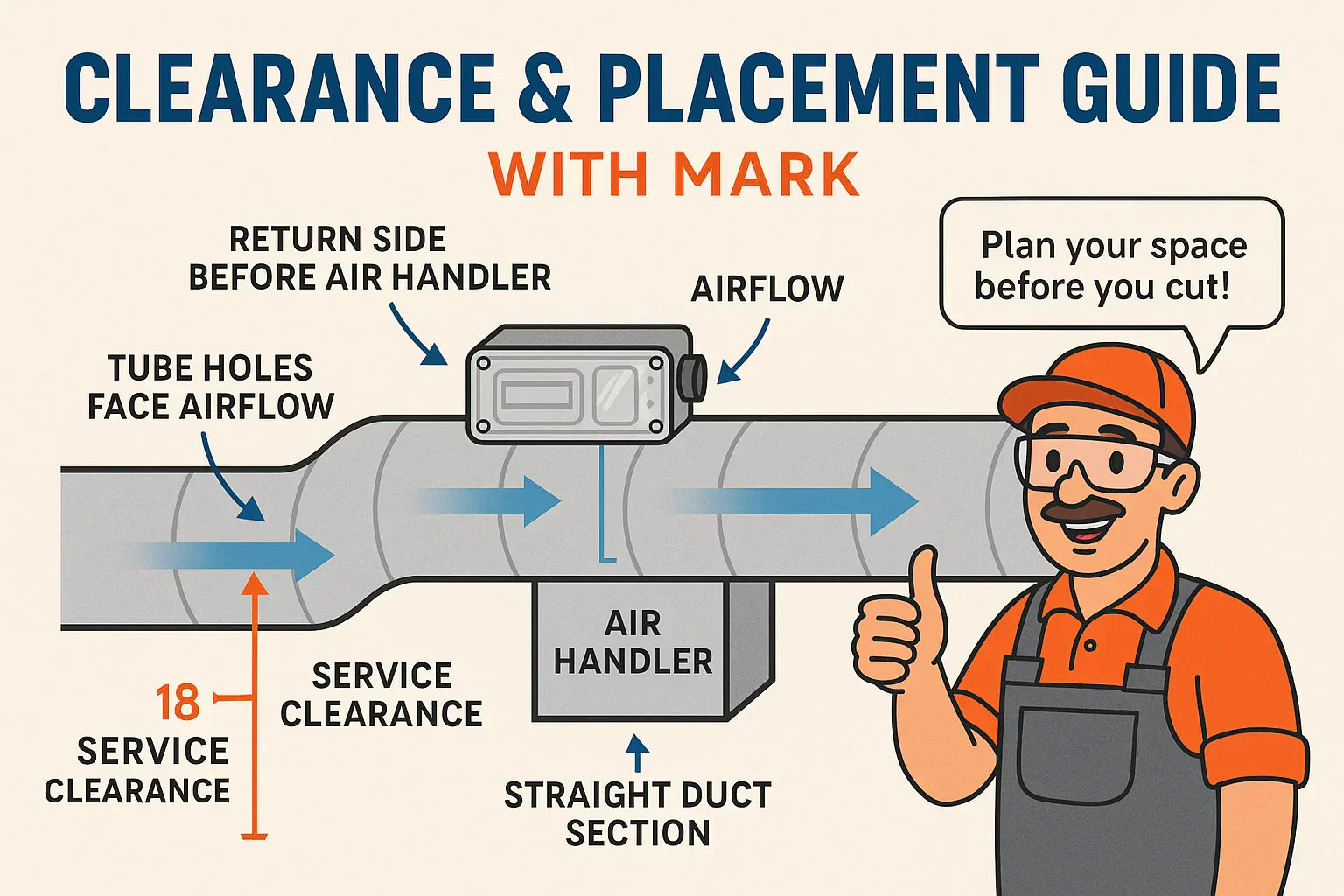

🔹 Service Clearance

-

NFPA 72 requires 18 inches of service access in front of the detector.

-

You need space to:

-

Open the cover.

-

Remove the sampling tube.

-

Test with smoke aerosol.

-

📌 Mark’s note: Don’t wedge it in a crawlspace where you can’t reach it. The inspector made me re-cut because I didn’t leave enough clearance for future testing.

🌬️ Best Placement for Airflow

Even if the detector physically fits, airflow is the bigger issue.

🔹 General Rule

Install on the return air side of the system, before filters and fans.

Why?

-

Filters trap dust, but they also disrupt airflow.

-

Fans create turbulence that messes with smoke sampling.

🔹 Straight Duct Section

-

Place on a straight run, at least 6 duct diameters downstream from bends or dampers.

-

Avoid elbows, transitions, or mixing boxes.

📌 Mark’s story: My first install was 2 feet from a damper. The airflow test failed because turbulence made the sample inconsistent. I had to re-install further upstream.

🔧 Sampling Tube Orientation

One of the most common mistakes I see online is backwards sampling tubes.

🔹 Correct Setup

-

Holes must face into the airflow.

-

Tube must span 70–100% of duct width.

-

End must be capped to prevent bypass.

-

Exhaust tube should return sampled air downstream.

🔹 Why It Matters

If the tube is reversed:

-

Smoke bypasses the holes.

-

Detector may not trigger until it’s too late.

📌 Mark’s reminder: I once flipped mine the wrong way. When I tested with aerosol, nothing happened. Always check airflow direction arrows before cutting.

🛠️ Common Installation Mistakes to Avoid

Here are the errors I’ve seen (and made):

-

Installing on the supply side.

-

Detectors belong on the return side.

-

Supply air is filtered and less likely to carry smoke.

-

-

Mounting too close to filters.

-

Filters block smoke particles.

-

Causes missed detection or false alarms.

-

-

No service clearance.

-

If you can’t reach the test button, you’ll fail inspection.

-

-

Skipping airflow verification.

-

NFPA requires a smoke test.

-

Tissue test at the exhaust tube can catch airflow problems.

-

📌 Mark’s advice: Don’t rush the placement. Measure, plan, and think about long-term maintenance.

📊 Fit in Different HVAC Systems

🏡 Residential Single-Family Homes

-

Most systems are under 2,000 CFM, so detectors aren’t usually required.

-

But if you have a large system, there’s usually space in the return plenum.

🏢 Small Commercial Rooftop Units

-

Most RTUs over 2,000 CFM require detectors.

-

Often installed right in return duct above the curb.

-

May need multiple detectors if system has multiple air handlers.

🏬 Multi-Family Apartments or Condos

-

Central air handlers almost always require detectors.

-

Inspectors check duct placement carefully.

📌 Mark’s takeaway: My duplex had a central air handler. There was plenty of space in the return, but I had to move the detector twice before the inspector was satisfied.

📜 Compliance References

🔹 NFPA 90A (HVAC Fire Safety)

-

Requires detectors in systems ≥ 2,000 CFM.

-

Placement on return side before fans and filters.

🔹 NFPA 72 (Fire Alarm & Signaling Code)

-

Requires accessible test/reset.

-

Requires annual functional testing.

🔹 System Sensor D4120 Datasheet

-

Provides clearance diagrams.

-

Lists duct size requirements for sampling tubes.

🔹 IMC & IFC (International Codes)

-

Mirror NFPA requirements.

-

Adopted in most jurisdictions.

📌 Mark’s note: Codes aren’t suggestions. If you ignore them, your inspector will make you redo it.

🧪 Airflow Verification Test

Once installed, you need to prove the detector is sampling correctly.

🔹 Methods

-

Tissue test: place tissue at exhaust tube—it should flutter.

-

Aerosol test: insert smoke into sampling tube, confirm alarm + fan shutdown.

🔹 Why It’s Required

-

Ensures the detector is in the right place.

-

Prevents false confidence in a poorly installed unit.

📌 Mark’s lesson: My first airflow test failed. It was embarrassing, but better to fail in front of the inspector than in a real fire.

🛠️ Tools & Materials Checklist

To plan clearance and placement, I used:

-

Tape measure (for duct size & clearance).

-

Drill with hole saw (for sampling tube holes).

-

Foil HVAC tape (for sealing).

-

Ladder (to access return plenum).

-

Test aerosol spray.

📌 Mark’s tip: Don’t cut until you’ve triple-checked measurements and airflow direction.

📊 Real-World Planning Scenarios

Scenario 1 – Small Office HVAC

-

2,500 CFM rooftop unit.

-

Detector installed in straight return section before filter.

-

Clearance left for annual testing.

-

Passed inspection first time.

Scenario 2 – Apartment Building

-

4,000 CFM air handler serving multiple units.

-

Inspector required two detectors (main return + secondary return).

-

Labor doubled, but it was non-negotiable.

Scenario 3 – Single-Family Home

-

1,200 CFM furnace.

-

Detector not required by code.

-

Owner installed anyway for extra safety.

📌 Mark’s takeaway: Requirements vary, but airflow and clearance always matter.

✅ Key Takeaways

-

The D4120 will fit in most systems—but only if you plan carefully.

-

Always mount on the return side, before filters and fans.

-

Leave 18 inches clearance for testing and service.

-

Place on a straight duct run with laminar airflow.

-

Sampling tubes must face into the airflow.

-

Inspectors will require an airflow verification test.

📌 Mark’s bottom line: Plan your space before you cut. It saves time, money, and headaches.

🔗 Verified References

📝 Final Word from Mark

I’ll be honest: I thought clearance and placement were “details” that didn’t matter. But after cutting one wrong hole and failing my first airflow test, I learned the truth:

If you don’t get clearance and airflow right, your detector is useless.

The Daikin D4120 is a solid unit, but even the best equipment won’t save you if you install it in the wrong spot. Plan carefully, measure twice, and always think about future testing and inspections.

Now when I look at my installed detector, I know it’s not just filling a code requirement—it’s in the right place to actually protect lives.

In the next topic we will know more about: Accessories You Might Need: Remote Test Stations, Sampling Tubes & Relays Explained