When you're investing in a home heating system, the internal material isn't just a technicality—it's the foundation of long-term performance. For Mike Sanders, a smart, experienced homeowner who values durability, reliability, and upfront honesty from his equipment, choosing between cast iron and stainless steel boilers is a decision that affects comfort, cost, and peace of mind for decades.

This guide breaks down the pros and cons of cast iron vs. stainless steel boilers with real-world insight and manufacturer-backed data.

🧱 Cast Iron Boilers: Proven, Rugged, and Familiar

🔹 What Is a Cast Iron Boiler?

Cast iron boilers use heavy cast iron sections to hold water and transfer heat. They’ve been used for over 100 years, and their design is time-tested. The Weil-McLain CGA-4 is a perfect example of this type.

🔍 Benefits

-

Longevity: Often lasts 30+ years with proper care

-

Thermal Mass: Thick cast iron retains heat and minimizes temperature swings

-

Simple Maintenance: Fewer moving parts than condensing boilers

-

Reliability in Old Systems: Ideal for gravity-fed or large-radiator setups

⚠️ Drawbacks

-

Weight: Very heavy; tougher and costlier to install

-

Lower Efficiency: Most are 80–86% AFUE (non-condensing)

-

Corrosion Risk if Leaks Occur: Internal water leaks or oxygen infiltration can cause rust

🧪 Stainless Steel Boilers: Modern, Light, and High-Efficiency

🔹 What Is a Stainless Steel Boiler?

Stainless steel boilers are most common in modern high-efficiency condensing systems. They use lighter heat exchangers designed to withstand the acidic condensate created by low-temperature operation.

🌟 Benefits

-

High Efficiency: Up to 95% AFUE ratings in ENERGY STAR models

-

Lighter Installation: Easier to transport and install

-

Compact Size: Ideal for tight utility rooms

-

Advanced Controls: Often paired with modulating gas valves and smart thermostats

⚠️ Drawbacks

-

More Maintenance: Requires annual flushing and pH level monitoring

-

Shorter Lifespan: Typical life expectancy is 15–20 years

-

Sensitive to Water Quality: Hard or acidic water can damage heat exchangers

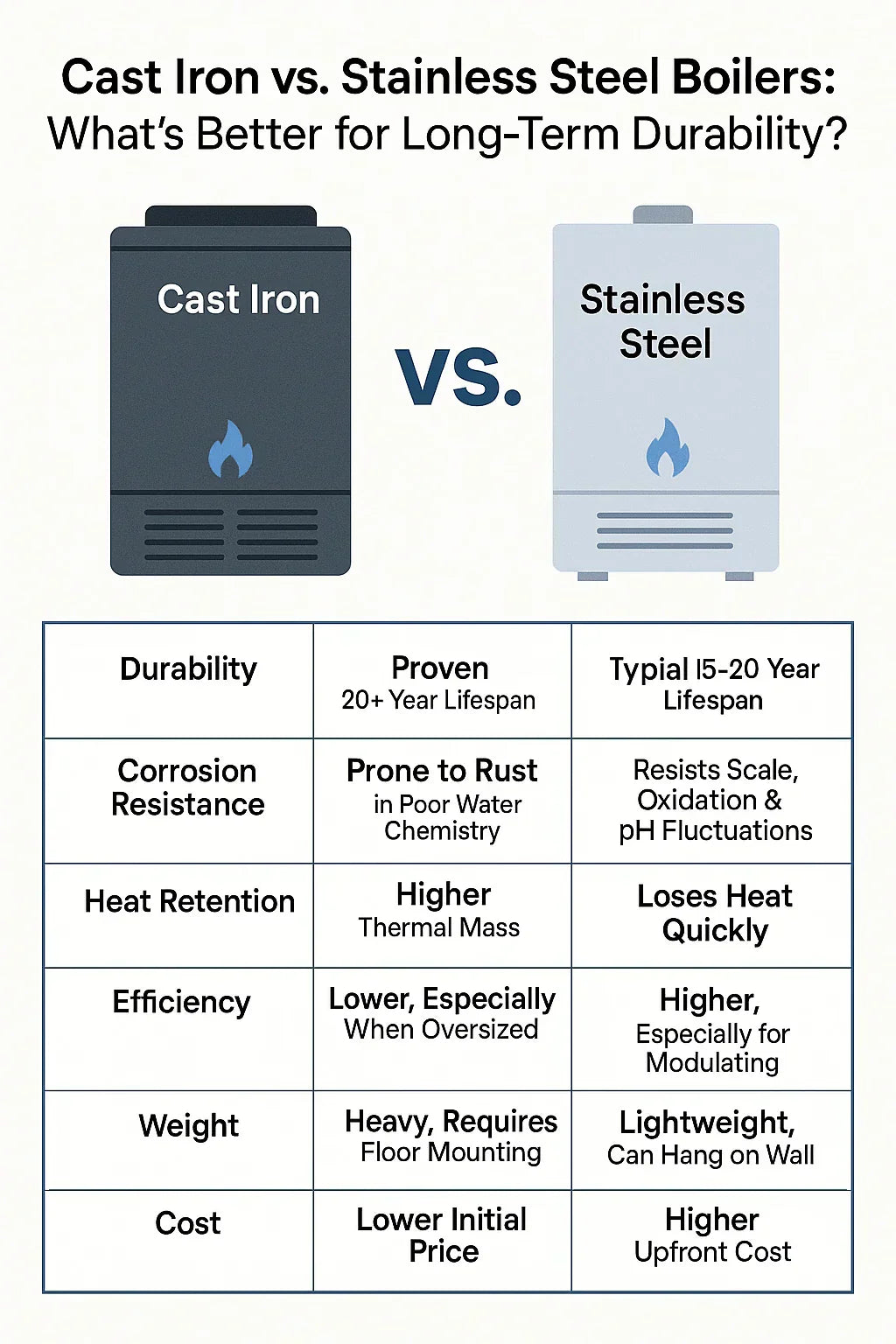

🆚 Head-to-Head: Cast Iron vs. Stainless Steel Boilers

| Feature | Cast Iron Boiler | Stainless Steel Boiler |

|---|---|---|

| Lifespan | 25–35 years | 15–20 years |

| Efficiency (AFUE) | 80–86% | 90–95% |

| Installation Weight | Heavy | Lightweight |

| Maintenance Frequency | Low (1–2x/decade service) | High (annual flushing recommended) |

| Water Quality Sensitivity | Medium | High |

| Ideal Use Case | Radiator systems, older homes | New builds, radiant floor systems |

🧰 Real-World Application: What Mike Sanders Needs to Know

Mike owns a 2,000 sq. ft., well-insulated home in a cold region. He’s not chasing the absolute highest efficiency—he’s after value and longevity. Here’s why the cast iron CGA-4 wins for him:

-

It will integrate well with his existing radiators

-

It's built for decades of life with minimal service

-

He's not dealing with high-acid condensate or complex venting

However, if Mike were in a newer home with radiant floor heating, or prioritizing carbon savings, a stainless steel condensing unit might offer faster returns.

🌐 External Resources for Deep Dive

✅ Bottom Line: Which One Should You Buy?

-

Choose cast iron if you want proven reliability, long-term durability, and simple service—even at slightly lower efficiency.

-

Choose stainless steel if you have excellent water quality, newer hydronic layouts, and prefer high AFUE ratings with modulating controls.

For Mike Sanders—and homeowners like him—the Weil-McLain CGA-4 delivers excellent value, especially in older or traditional radiator homes.

In the next topic we will know more about: How Much Does a Weil-McLain CGA-4 Boiler Installation Cost in 2025?