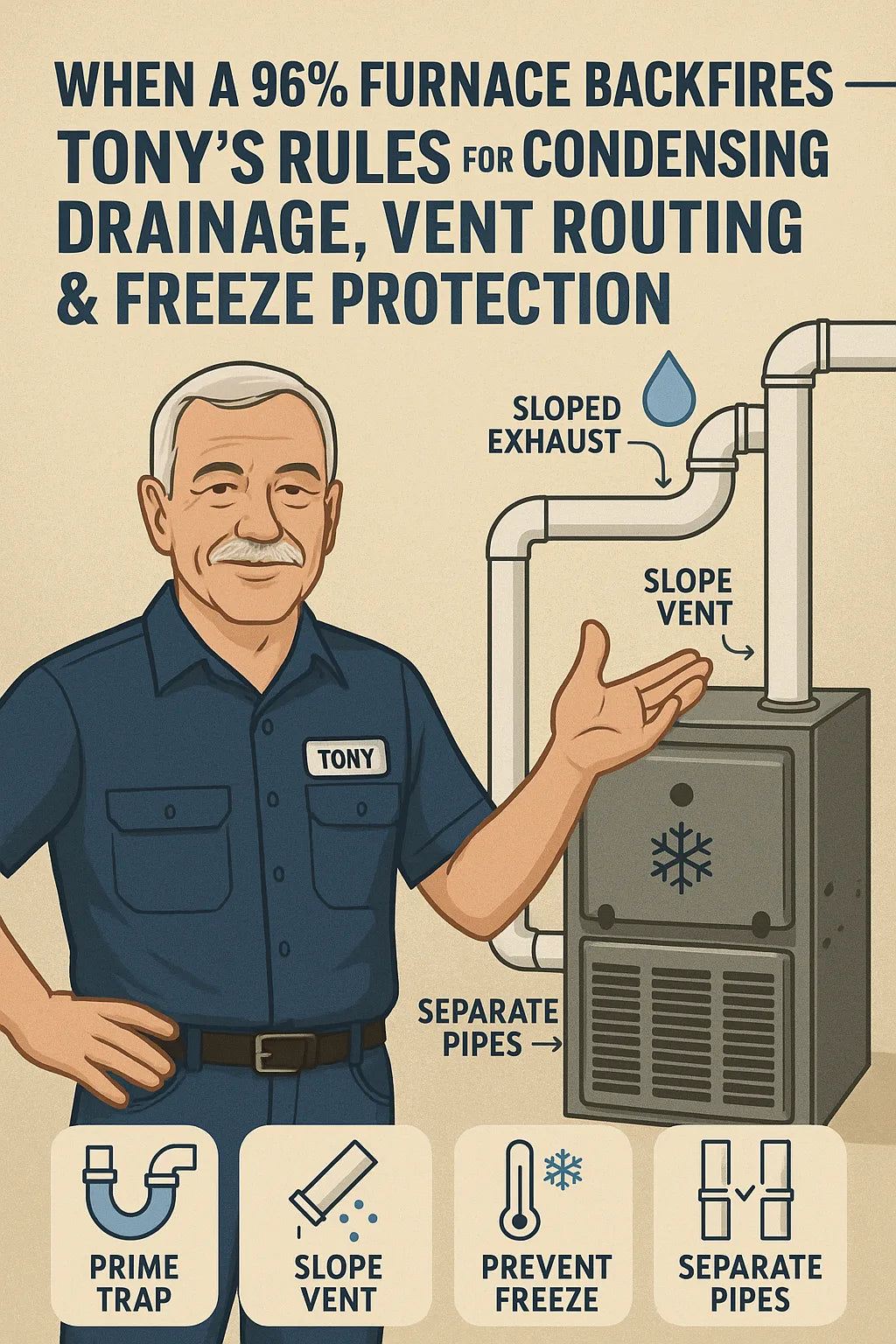

🏠 Introduction: High Efficiency Isn’t “Plug and Play” — It’s “Install It Right or Pay the Price”

Homeowners love 96% AFUE furnaces. Manufacturers love them. Utility companies love them.

But Tony — who’s been fixing HVAC installs for over 35 years — says something few techs want to admit:

“A 96% furnace can run worse than an 80% if you ignore drainage and vent routing.”

He’s not joking.

High-efficiency furnaces produce gallons of condensate per day, rely on precise vent pitch, and need freeze protection in ways older furnaces didn’t. One bad slope, one sagging vent pipe, or one clogged trap can turn a 96% furnace into:

-

A locked-out furnace

-

A water-logged furnace

-

A rust factory

-

A frozen PVC popsicle

-

Or a system that short-cycles ALL winter

This article breaks down Tony’s real-world rules — the ones he teaches every junior tech — to keep 96% furnaces running safely, silently, and reliably for decades.

3 Ton 15.2 SEER2 80,000 BTU 96% AFUE Goodman Upflow Air Conditioner System

❄️ 1. Why 96% Furnaces Create So Many Problems When Installed Wrong

A 96% AFUE furnace extracts so much heat from the combustion gases that the exhaust temperature drops below the dew point.

So water condenses inside the furnace, inside the vent, and inside the drain lines.

How much?

A typical 96% furnace creates:

0.75–1.25 gallons of condensate per hour of runtime

If that water doesn’t exit quickly and correctly:

-

It backs up into the secondary heat exchanger

-

It floods the inducer

-

It leaks onto the control board

-

It freezes in vent lines

-

It triggers pressure switch lockouts

-

It produces error codes the homeowner can’t diagnose

Tony says:

“If you install a 96% furnace without thinking like a plumber, you’re in trouble.”

✔️ High-efficiency condensation explanation: https://www.energy.gov/energysaver/furnaces-and-boilers

🧊 2. The Three Enemies of Every 96% Furnace

Tony has seen thousands of high-efficiency installs.

He says 96% furnaces always get taken down by one of these three enemies:

1. Standing water in the secondary heat exchanger

Caused by:

-

Blocked trap

-

Incorrect vent pitch

-

Sagging drain tubes

-

Algae buildup

2. Frozen vent or drain lines

Caused by:

-

Installing PVC without insulation in cold spaces

-

Running outdoors too long before termination

-

Downhill slope outdoors

-

Wind blowing into termination

3. Vent pressure imbalance

Caused by:

-

Too many elbows

-

Wrong pipe diameter

-

Exhaust & intake too close

-

Negative pressure room

-

Flue intake pulling exhaust fumes

Tony calls them:

“Water, Ice, and Pressure — the death triangle of bad 96% installs.”

💧 3. Tony’s Drainage Rule #1 — The Trap Must Be Accessible, Visible & Cleanable

Every 96% furnace requires a condensate trap because the system uses negative pressure inside the heat exchanger.

Tony’s rules:

✔️ Trap must be manufacturer-approved

Never substitute a random P-trap.

✔️ Trap must be lower than all internal drain connections

Gravity matters.

✔️ Trap must be fully accessible

Hidden traps = future service nightmare.

✔️ Trap must be removable

Tony replaces traps yearly in harsh climates.

✔️ Trap must be primed

An unprimed trap causes:

-

Gurgling sounds

-

Pressure switch lockouts

-

Flue gas recirculation

-

Water sloshing noises

Tony’s saying:

“If you don’t prime the trap, the furnace screams at you.”

✔️ Condensate drainage guidelines: https://www.acca.org

🛠️ 4. Drainage Rule #2 — No Sags, No Dips, No Uphill Runs

Condensate must flow downhill — always.

A drain hose that sags like a hammock will collect water, algae, and slime. That creates:

-

Pressure switch issues

-

Overflow

-

Backup into the collector box

Tony’s rule:

“If it’s not sloped, it’s stopped.”

He demands:

-

Secure mounting clips every 12–16 inches

-

¼” drop per foot of run

-

No tight radius bends

-

Smooth internal surfaces (rigid tubing preferred)

-

No barbed fittings if avoidable

✔️ Plumbing slope guidance (ENERGY STAR): https://www.energystar.gov

🌬️ 5. Vent Rule #1 — Exhaust Must Slope BACK to the Furnace

This rule causes more failures than every other mistake combined.

PVC exhaust venting must always slope TO the furnace.

Tony prefers:

-

¼” per foot slope back

-

No exceptions

-

No flat runs longer than 3 feet

Why?

Moisture condenses inside the vent.

If the vent slopes away from the furnace:

-

Water sits in the vent

-

Inducer floods

-

Furnace locks out

-

Freezing risk increases

-

PVC joints crack

The number of installers who slope vents the wrong way is shocking.

Tony says:

“Slope it wrong and you just built a water slide aimed at your heat exchanger.”

✔️ PVC vent installation standards: https://www.nfpa.org

🚫 6. Vent Rule #2 — No Horizontal Runs in Unconditioned Spaces

Cold spaces include:

-

Garages

-

Attics

-

Crawlspaces

-

Uninsulated basements

-

Exterior walls

PVC + freezing air = ice blockage inside the vent.

Tony’s rules:

✔️ if the vent MUST pass through a cold zone:

-

Insulate the pipe

-

Use heat tape (in extreme climates)

-

Add a secondary drain hole at the furnace

-

Minimize exposure length

✔️ preferred:

Route venting through conditioned spaces only.

Tony explains:

“PVC doesn’t care that the manual says it’s okay.

PVC listens to the weather, not the manual.”

🌀 7. Vent Rule #3 — Intake & Exhaust Must Be Properly Separated

If intake air is too close to exhaust:

-

Furnace re-breathes CO₂

-

Flame weakens

-

Ignition becomes unstable

-

Condensate production increases

-

Efficiency drops

-

Burners get noisy

-

Soot forms

Tony’s spacing rules (he uses them on every Goodman install):

-

Minimum 12 inches separation

-

Prefer 24–36 inches depending on wind patterns

-

Intake should always be upwind of exhaust

-

Both terminations should be the same length of pipe

✔️ Vent location requirements: https://www.goodmanmfg.com

🧊 8. Winter Rule — Protect the Drain Line Like It’s a Water Pipe

A frozen drain line = furnace lockout.

Signs of freeze:

-

Gurgling drain trap

-

Water leaking from furnace base

-

Blower running but no heat

-

Pressure switch error

-

Inducer humming without firing

Tony protects drain lines using:

✔️ Foam insulation

Closed-cell foam prevents freezing down to moderate temperatures.

✔️ Heat tape (extreme climates)

He uses self-regulating heat cable approved for PVC.

✔️ Interior routing

Drain line should stay inside the building envelope whenever possible.

✔️ Air gap protection

Proper air gap before the drain enters the home’s plumbing stack prevents cold-air siphoning.

Tony’s line:

“If your drain pipe sees your breath, it will freeze.”

✔️ Freeze protection fundamentals:

https://www.energy.gov/energysaver/weatherize/insulation

🧯 9. Pressure Switch Rules — Don’t Make the Furnace Fight for Air

Pressure switches are not the problem.

They are the messenger.

When a furnace won’t start due to a pressure switch error, Tony knows the real causes are:

-

Blocked intake

-

Sagging vent pipe filled with water

-

Frozen vent

-

Incorrect pipe size

-

Too many elbows

-

Condensate flooding the inducer

-

Negative pressure in the mechanical room

Tony measures:

-

Intake pressure

-

Exhaust pressure

-

Vent length

-

Number of elbows

-

Vent pipe diameter

-

Combustion air availability

His rule:

“If the pressure switch is tripping, you installed something wrong — fix that first.”

✔️ Venting & pressure guide: https://www.ahridirectory.org

🧪 10. Combustion Rule — Avoid Mechanical Rooms That Go Negative

96% furnaces can be installed in closets, small rooms, and sealed spaces — IF the venting and combustion air rules are followed.

Tony’s preferred setups:

Direct vent (sealed combustion)

-

Furnace pulls combustion air from outside

-

Mechanical room stays neutral

-

No backdraft risk

-

No pressure imbalance

Non-direct vent (rarely recommended)

The furnace pulls air from the room, which requires:

-

Large combustion air openings

-

Makeup air

-

No competing exhaust fans (bath/kitchen)

-

No dryers nearby

Tony warns:

“Tight houses don’t give up air. The furnace will suck until it chokes.”

🧰 11. Tony’s Real-World Case: The “Brand New 96% Furnace That Died in a Week”

A contractor installs a new 96% Goodman furnace.

Homeowner calls Tony in a panic:

-

Furnace shuts off every few minutes

-

Water leaking around bottom

-

Cold rooms

-

Inducer roaring

-

Pressure switch error

Tony inspects and finds:

❌ Vent sloped AWAY from furnace

Holding almost 2 quarts of water.

❌ Drain trap installed ABOVE internal ports

Water backing into collector box.

❌ Intake and exhaust only 6" apart

Recirculating flue gases into intake.

❌ Drain line routed through freezing crawlspace

Frozen solid block.

Tony fixes everything:

-

Re-routes vent with proper slope

-

Installs correct trap

-

Places intake/exhaust 24" apart

-

Insulates and reroutes drain line

-

Re-primes trap

-

Confirms ΔT and pressure readings

Now the system runs flawlessly.

Tony’s conclusion:

“The furnace wasn’t bad. The installer was.”

🏁 Conclusion: High Efficiency Requires High Attention

A 96% furnace is incredible when installed right.

But when installed wrong, it becomes:

-

Noisy

-

Short-lived

-

Freeze-prone

-

Waterlogged

-

Inefficient

-

Unsafe

Tony’s final message to techs and homeowners:

“You don’t install a 96% furnace — you engineer it.”

Because:

-

Drainage matters

-

Vent slope matters

-

Freeze protection matters

-

Pressure balance matters

-

Termination location matters

-

Trap size and priming matter

If any of these are wrong, a high-efficiency furnace backfires.

Buy this on Amazon at: https://amzn.to/4hyDyKH

In the next topic we will know more about: The Line Set Trap — Why Your AC Can Lose a Full Half-Ton of Capacity from Improper Length or Rise