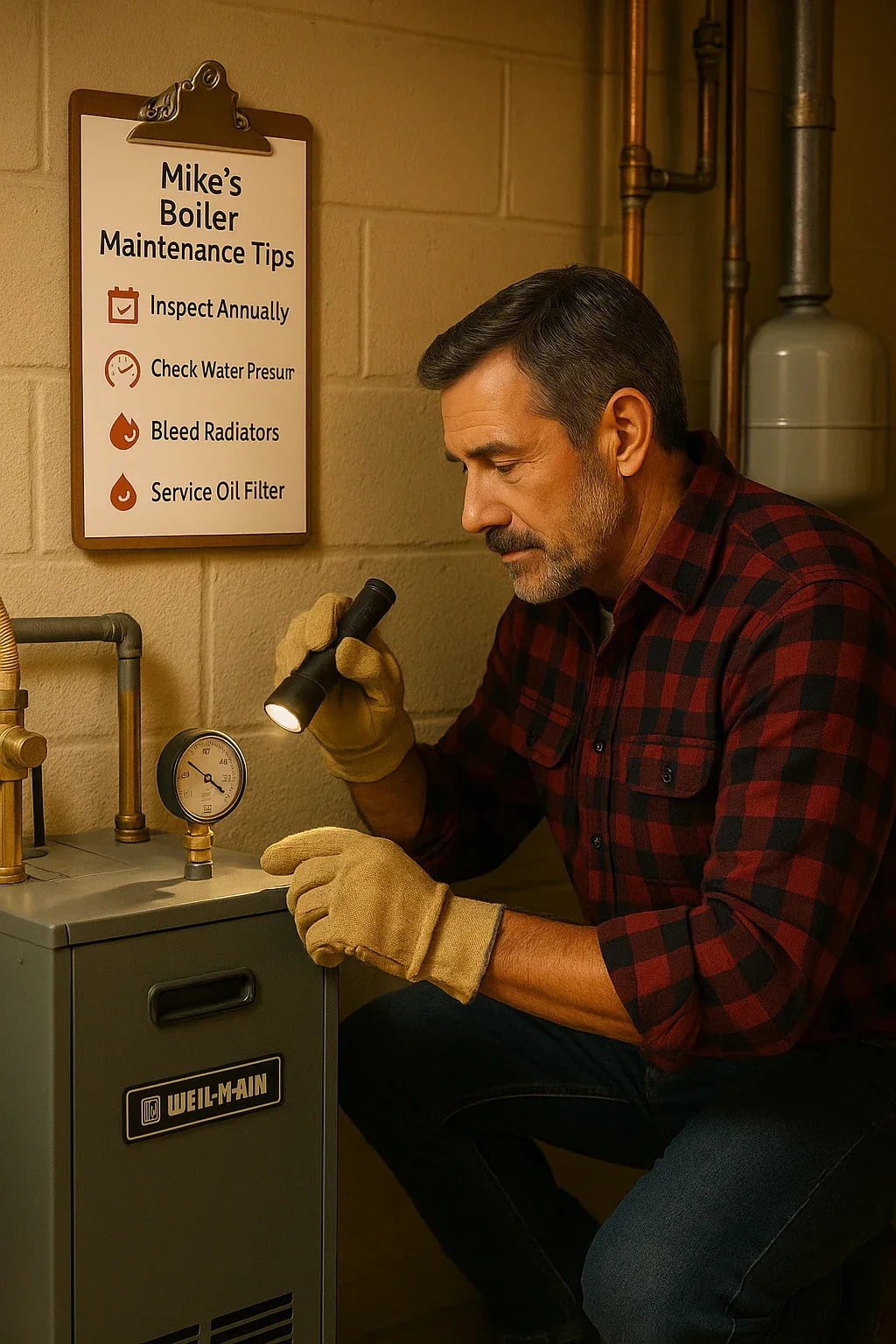

For Mike Sanders—and homeowners like him who want their boiler to last decades with minimal trouble—the Weil-McLain CGA-4 offers a solid foundation. But even the most durable cast iron system needs regular maintenance to run efficiently and avoid costly breakdowns.

This guide breaks down exactly what you should do seasonally, annually, and every few years to keep your CGA-4 boiler in peak condition.

🛠️ 1. Fall Startup Checklist (Before Heating Season Begins)

-

✅ Inspect pressure gauge: Should read 12–15 psi when cold

-

✅ Check expansion tank: Ensure diaphragm isn’t waterlogged

-

✅ Test thermostat: Set to call for heat and confirm boiler kicks on

-

✅ Clean air vents and purge valves: Prevent airlocks in zones

-

✅ Inspect flue and chimney: Remove nests, soot, or blockages

➡️ Start every season clean and safe—especially important for systems that sit idle all summer.

❄️ 2. During Winter: Weekly or Monthly Checkups

-

🔄 Listen for short cycling: May indicate thermostat, air, or pump issue

-

🔧 Watch for dripping relief valve: Can signal overpressure or expansion tank failure

-

💧 Check for water leaks: Especially at fittings and valves

-

🔥 Confirm burner ignition: Should ignite smoothly, without delay or soot

-

💨 Monitor vent draft: Cold flue can reduce efficiency or trigger condensation

➡️ Mike’s rule: 5-minute boiler check every weekend = years of added life.

🌼 3. Spring Shutdown Guide

-

📴 Turn off boiler power and fuel supply

-

💦 Drain and flush if recommended by your installer

-

🧼 Clean burners and inspect ignition

-

🧰 Inspect controls and wiring

-

💨 Cover exhaust or flue pipe (optional, keeps out moisture and debris)

Energy.gov Seasonal Boiler Shutdown Tips

🔄 4. How to Bleed Air from Your Radiators or Baseboards

-

Step 1: Turn off heat and let system cool

-

Step 2: Use bleed key (for radiators) or purge valve (for baseboards)

-

Step 3: Open slowly until air hisses, then water flows

-

Step 4: Close valve and recheck system pressure

➡️ Air in the system reduces flow and heat transfer—bleed zones once per season or as needed.

Weil-McLain Radiator Maintenance

🧼 5. Flushing the Boiler: When and How

💧 What Flushing Does:

-

Removes sediment, rust flakes, or scale from the heat exchanger

-

Improves water flow and efficiency

-

Reduces stress on the pump and circulators

🔧 When to Flush:

-

Every 3–5 years (standard system)

-

Every 1–2 years (hard water areas)

🧰 How to Flush:

-

Close feed and isolate boiler

-

Connect hose to boiler drain

-

Open zone valves and drain system

-

Refill, bleed air, check pressure

➡️ Pro tip: Add boiler conditioner after flushing to prevent internal corrosion.

🔍 6. Signs Your Boiler Needs Attention

| Symptom | Likely Cause | Action Needed |

|---|---|---|

| Noisy radiators/baseboards | Air in system | Bleed system |

| Frequent resets | Control issue or blocked vent | Call technician |

| Slow warm-up | Sediment or poor circulation | Flush + check pump |

| Dripping pressure valve | High pressure or tank failure | Replace relief valve |

| Burner won’t ignite | Flame sensor dirty or bad gas mix | Clean burner, inspect gas |

👨🔧 7. What to Expect During a Professional Annual Tune-Up

-

Combustion analysis (draft, CO, flame quality)

-

Heat exchanger inspection

-

Burner and ignition cleaning

-

Water chemistry check

-

Valve and pump performance test

-

Safety switch and sensor calibration

Estimated cost: $150–$300

Time: 1.5–2 hours

➡️ Mike’s reminder: Schedule in early fall before pros get booked.

🧰 8. Tools Mike Should Keep in His Toolbox

-

Bleed key or radiator wrench

-

Pressure gauge (inline or handheld)

-

Non-contact infrared thermometer

-

Backup ignitor or thermocouple (if applicable)

-

Flashlight + inspection mirror

-

Emergency shutoff tag

🧮 9. How Maintenance Saves You Money

| Task | Average Cost Avoided |

| Flushing boiler | $300–$600 scale repair |

| Bleeding air | $100–$300 in pump strain |

| Checking pressure | $200–$400 valve replacement |

| Fall tune-up | Prevents $800+ winter failure |

➡️ Small tasks prevent major costs—just like oil changes for your car.

✅ Conclusion: Mike’s Long-Term Maintenance Plan

Mike Sanders wants reliable heat, no surprises, and the satisfaction of hands-on care. By following:

-

A fall startup checklist

-

Monthly checks during winter

-

Spring shutdown

-

Occasional flushing and annual tune-ups

...he can expect 25+ years of strong performance from his Weil-McLain CGA-4 boiler—with fewer repairs, better efficiency, and lower lifetime costs.

With a basic toolset, attention to detail, and an annual visit from a pro, Mike stays in control—and stays warm all winter long.

In the next topic we will know more about: Do I Need a Chimney Liner for My Gas Boiler? Venting Code Requirements in 2025